Triblock

Triblock Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 30 Pieces Per Month

- Delivery Time

- 8 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Packing Only

- Main Domestic Market

- All India

- Certifications

- CE & ISO Certified

About Triblock

Triblock

![]() Salient Features:

Salient Features:

|

GMP Model based on advanced technology. |

|

| Single Operator for Three Operations. | |

| Rinse Fill & Seal cycle, fully Trio-block for total filling hygiene. The whole process is automatic | |

| Bottle in-feed using high pressure air conveyor with air filter on suction side. | |

| Less Floor Area. | |

| No Contamination as immediate sealing of filled bottles. | |

| Centralized Volume Adjustment System- no down time in volume settings. | |

| No Bottle No Fill for Individual head, hence no spillages. | |

| Torque adjustable capping heads using PICK & PLACE provided.. | |

| Machine is fully Neck holding by design, So no change part required for different size of bottles | |

| Automatic PLC control speed regulation. | |

|

The advanced Programmed Logic Controller (PLC) is adapted to control the machine runs automatically, air conveyor system is adopted in bottle entry section and belt |

|

| Machine covered with SS 304 frame & Acrylic Doors for total filling hygiene | |

| Placing of Cap Feeder Outside Trio-block-avoid entering of dust in it. | |

| Better finish imported polished, laminated S.S. sheet used. | |

| Separate variator drive to control speed of conveyor. | |

| Self Lubricating UHMW- PE Guide profile for Low friction wear surface, smooth and noiseless conveying. | |

| Fully automatic rotor to rotor transfer without any human contact. It is convenient to operate with higher automation | |

| Safety Guard for Operation and Protection. |

|

Automatic Rotary Rinsing, Filling & Capping Machine is versatile, self-supported on stainless steel leg with height adjustable adjustment system. The machine is precision built on sturdy welded steel frame completely enclose in stainless steel sheet and doors are providing to facilitate the servicing of machine, work on gravity filling principle with rotary motion. The unit is made compact, versatile and enclosed in stainless steel elegantly matt finish body. No container No filling & No Sealing system arrangement is standard features of the machine. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

In-feed air conveyor fitted with high pressure air blower with filter fitted on the suction side. This conveyor feeds empty bottles into the in-feed rotor by neck holding mechanism of the Trio-block machine. The conveyor is mounted at right angles to the Trio-block machine. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The In-feed Rotor is transfer the bottle from In-feed Air Conveyor to the Rinsing rotor. The bottles are automatically picked up by the rinser rotor from in-feed rotor with neck holding & bring it to the grippers clamp. The grippers clamps turn them upside down means inverted positions which place the bottle mouth over the nozzle. Where the fountain type nozzle spray water in-side the bottle in series, each bottle being rinsed up to four seconds. Mechanical rinse valve provides the feature NO BOTTLE NO RINSING. Whenthe bottles are held at the neck, there is no distortion of the bottle profile. At the end of the rinsing cycle, the bottle is drained of most reschedule water, before being straightened out and handed over to the filling rotor for the filler operation. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The mechanical filling valves, mounted radically on the rotary filling tank, are actuated automatically by the bottles when lifted up to commence filling. Here again the bottles are held at the neck by neck holding grippers which ensures precise valve centering. Consequently, there is no bottle damage or water wastage during the filling operation. The main machine drive motor has variable speed A.C. Drive, by which the machine speed can be varied depending upon the bottle size to be run. Three position probe fitted in the filling tank automatically regulates the machine speed based upon product inflow, using a panel mounted PLC. NO BOTTLE NO FILLING system arrangement is standard features of the machine. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The feed container moving on transfer rotor, this transfer rotor feed the bottle from the filler rotor to the capper rotor. The Capper Rotor bringing the container below the sealing head in the subsequent indexing part, mean while the rotating head pickup a cap from the cap star wheel which is receiving from delivery chute of cap filling bowl, where the body and the neck of the container are positioned below the rotating head, where the sealing head is performing perfect operation of sealing. The Capping adopts a unique PICK & PLACE mechanism for capping in conjunction with an efficient bottle anti-turn device. The bottle is held at the neck firmly during capping to produce absolutely leak proof results. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Caps are fed into the machine by an automatic cap elevator having an S. S. 304 ground level hopper, which can hold up to three thousand caps. This hopper also an automatic agitator, which gets activated as soon as the caps stop moving inside the cap hopper. Thus, the elevator is never starved of caps. The elevator orientates and feeds caps at the desired rate to the capper rotor. Shortly before cap pickup the caps are exposed to UV light for sterilization. After capping, the bottles are .discharged on to the out-feed slate conveyor. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Advanced Automation for Precision Filling

The Triblock enhances productivity through its automatic and computerized PLC control, guaranteeing accurate and consistent performance. Electric drive ensures clean, low-maintenance operations. Adjustable filling volumes, from 100ml to 2000ml, make it adaptable to diverse production needs and liquid types.

Customizable for Your Requirements

Triblock machines are engineered with flexible voltage and power options to accommodate unique operational setups. The warranty period is also customizable, providing confidence and peace of mind to users. Interested parties can access the Triblock through a network of distributors, exporters, manufacturers, and suppliers across India.

FAQs of Triblock:

Q: How does the Triblock machine operate automatically?

A: The Triblock leverages an advanced PLC control system and computerized interface, allowing for automated filling, capping, and labeling processes. Operators can program and monitor the machine via its digital controls, minimizing manual intervention.Q: What materials are used in the construction of the Triblock?

A: The Triblock is constructed from high-quality stainless steel, ensuring robust durability, corrosion resistance, and hygienic operations suitable for food, beverage, or pharmaceutical industries.Q: When should I consider using the Triblock for my production line?

A: The Triblock is ideal for businesses seeking to automate liquid filling tasks for volumes between 100ml and 2000ml. It is particularly beneficial when scalability, consistency, and hygiene are crucialespecially in high-output or multi-product environments.Q: Where can the Triblock be sourced in India?

A: The Triblock is available throughout India via a network of authorized distributors, exporters, manufacturers, and suppliers. You can reach out for purchasing options or to request quotations and after-sales support.Q: What is the process for customizing the voltage, power, and warranty?

A: Customers can specify their preferred voltage, power, and warranty terms when placing the order. The manufacturer will tailor the machines configuration and service agreement to the clients operational and regional needs.Q: How is the Triblock machine maintained and what are its benefits?

A: Routine cleaning and basic inspection are recommended due to its stainless steel construction and electric drive, which reduce wear and maintenance. Benefits include operational efficiency, high hygiene standards, and reduced downtime.Q: What are the key usage and benefits of employing the Triblock machine?

A: Designed for automatic, high-precision filling, the Triblock optimizes labor, ensures product consistency, and reduces waste. Its adaptable design suits various industries, while computerized controls streamline user management and enhance productivity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Liquid Filling Machine Category

Volummetric Eight Head Liquid Filling Machine

Price 1000000 INR / Unit

Minimum Order Quantity : 1 Piece

Automatic Grade : Automatic

Drive Type : Electric

Material : SS

Warranty : 1 Year3

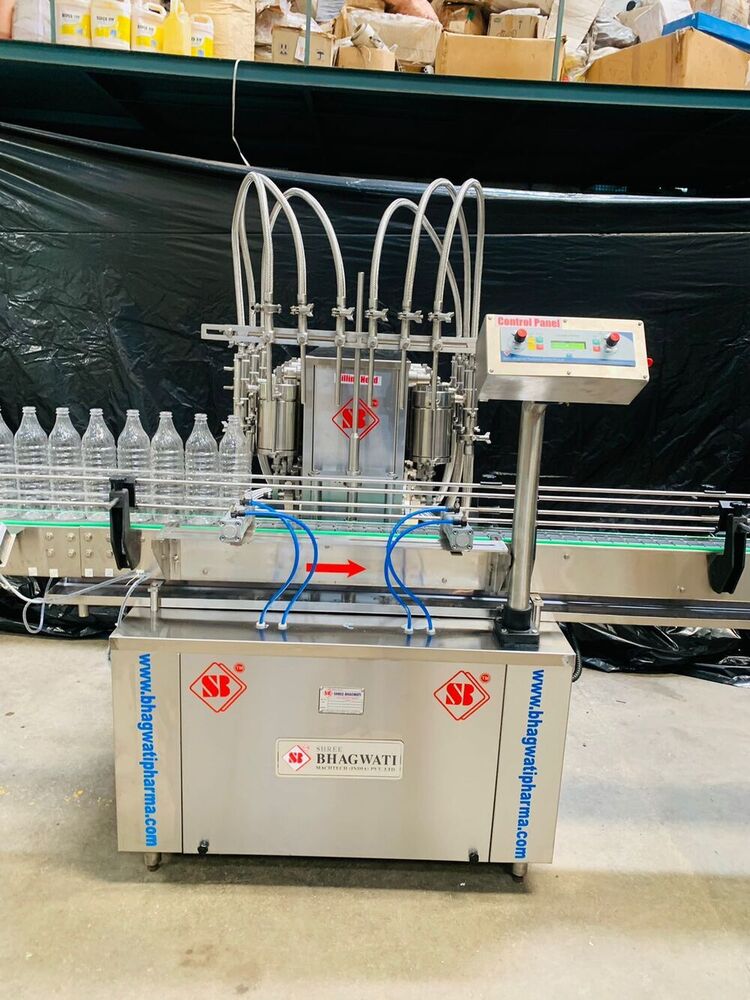

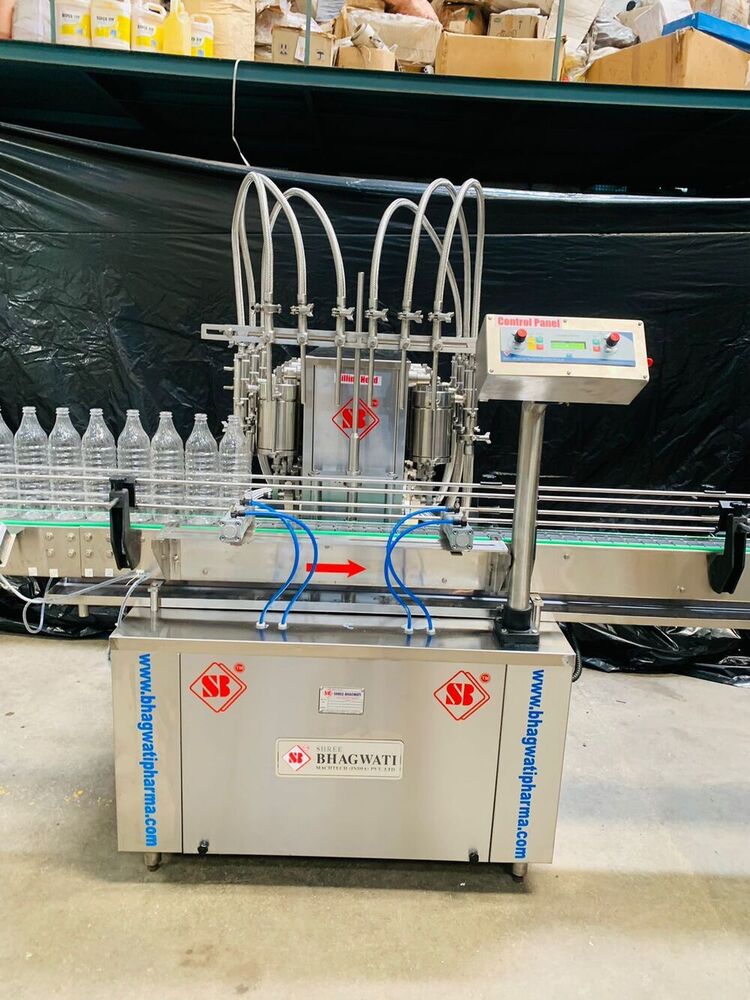

AUTOMATIC FOUR HEAD FILLING MACHINE

Price 300000.00 INR / Piece

Minimum Order Quantity : 01 Piece

Automatic Grade : Automatic

Drive Type : Electric

Material : Stainless Steel

Warranty : 1 year

6 Head Volumetric Essential Oil Filling Machine

Price 675000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Drive Type : Electric

Material : SS

Warranty : 1 Year

Automatic Honey Filling Machine

Price 500000-2000000 INR / Unit

Minimum Order Quantity : 1 Piece

Automatic Grade : Automatic

Drive Type : Electric

Material : SS

Warranty : 1 Year

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free