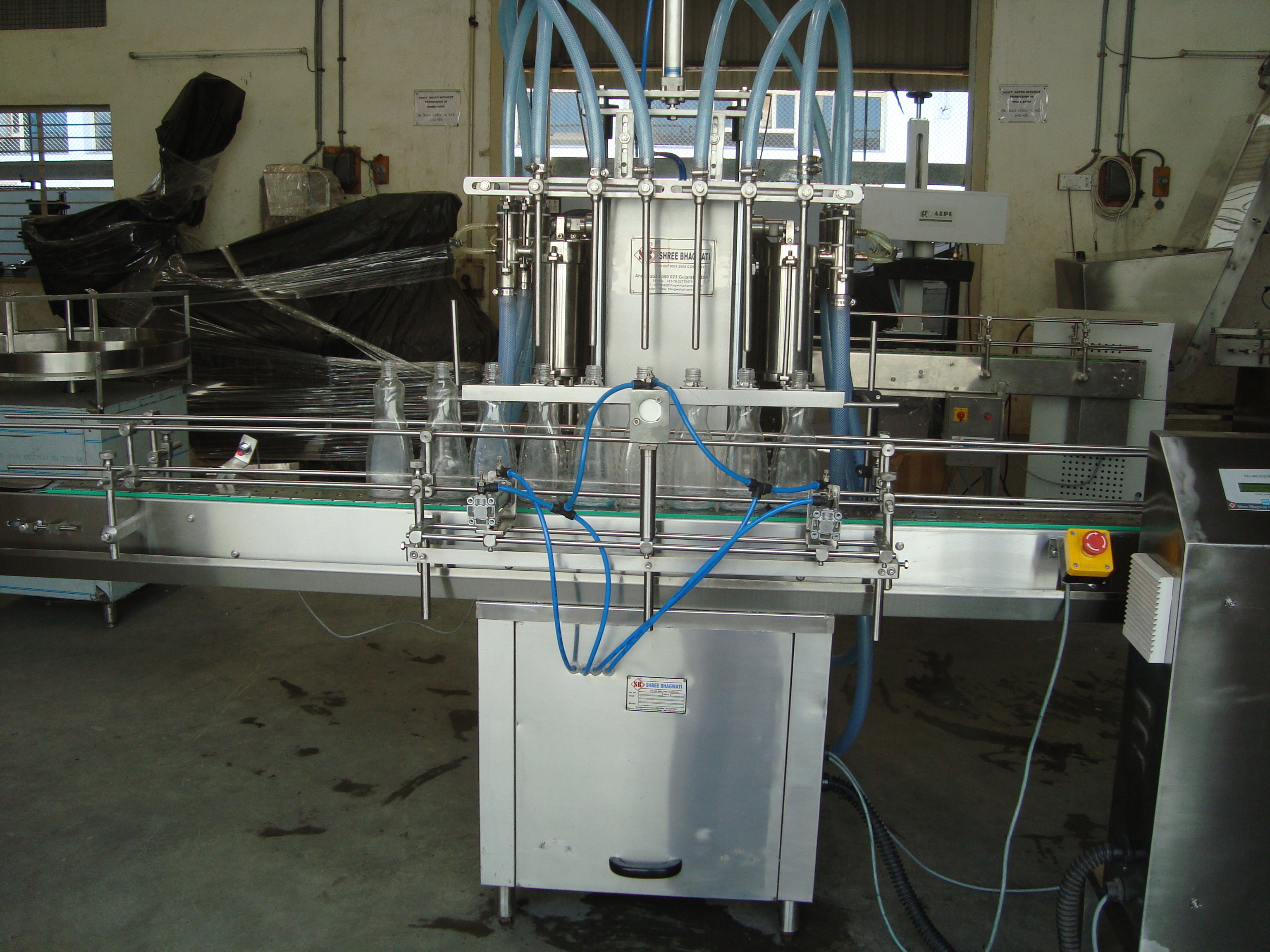

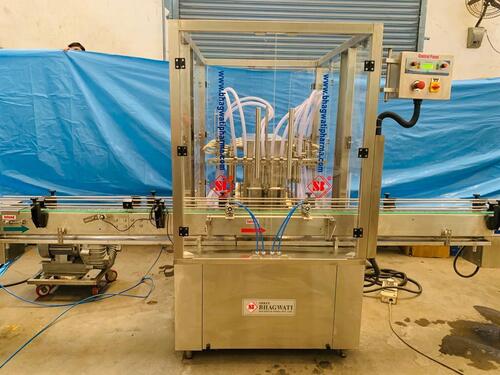

AUTOMATIC FOUR HEAD FILLING MACHINE

Price 300000.00 INR/ Piece

AUTOMATIC FOUR HEAD FILLING MACHINE Specification

- Product Type

- Automatic Filling Machine

- Material

- Stainless Steel

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Control

- Drive Type

- Electric

- Voltage

- As per customer required Watt (w)

- Warranty

- 1 year

AUTOMATIC FOUR HEAD FILLING MACHINE Trade Information

- Minimum Order Quantity

- 01 Piece

- Payment Terms

- Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Cash Against Delivery (CAD), Days after Acceptance (DA), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 30 Pieces Per Month

- Delivery Time

- 4-6 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden packing only

- Main Export Market(s)

- South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia, North America, Australia

- Main Domestic Market

- All India

- Certifications

- ISO and CE Certified

About AUTOMATIC FOUR HEAD FILLING MACHINE

| Model No. | SBLF-100 | |

| Out/Put | Up to 20-25 BPM ï depend on fill volume | |

| Filling Range | 10 ml to 1000 ml (With help of change parts) | |

| Direction of Movement | Left to Right | |

| Number of head/syringe | 4 Nos. | |

| Electrical | Main Machine | 2.0 HP / 415 Volts / 50 Hz. |

| Conveyor | 1.0 HP / 415 Volts / 50 Hz. | |

| Height of Conveyor | 860 mm to 910 mm adjustable. | |

| Net Weight | 600 Kgs. | |

| Change parts required | (A) Syringes. (B) Nozzle (C) Inlet & outlet hose pipe | |

Salient Features

The unit is made compact &versatile

S.S. Slat conveyor.

S.S. Elegantly MattFinished Body

No Container Nofilling system.

Reciprocating Fillingnozzle with self centring device

Pneumatically operatedbottle stopper

Advanced Automation with PLC Control

This filling machine integrates the latest PLC control system for optimized automation. Users benefit from touch-screen operations and computerized precision, allowing for smooth functioning and minimal human intervention. High-quality stainless steel construction ensures hygiene and longevity, making it suitable for demanding industrial environments.

Flexible Configuration for Diverse Needs

The voltage configuration can be tailored according to customer specifications, making the machine compatible with varied power setups across India. Whether you are an exporter, manufacturer, or distributor, this adaptability simplifies installation and guarantees consistent performance everywhere.

FAQs of AUTOMATIC FOUR HEAD FILLING MACHINE:

Q: How does the Automatic Four Head Filling Machine improve the filling process?

A: The Automatic Four Head Filling Machine utilizes advanced PLC-controlled automation and computerized functions, delivering rapid and precise filling across four simultaneous heads. This increases throughput and ensures consistent volumes, reducing product wastage and operational errors.Q: What types of materials can be processed with this machine?

A: Constructed from stainless steel, the machine accommodates a wide range of liquid products, including food, chemicals, and pharmaceuticals, maintaining high standards of safety and hygiene throughout operation.Q: When is the best time to schedule maintenance for this equipment?

A: Regular servicing aligns with the manufacturers recommendations, typically every six months or as usage intensity dictates. Scheduled checks help preserve reliability, and the included one-year warranty covers any necessary repairs during the initial period.Q: Where can the Automatic Four Head Filling Machine be installed?

A: This machine is designed for versatile installation in industrial environments across India, such as manufacturing plants, bottling facilities, and processing units. Its customizable voltage feature makes it suitable for diverse locations.Q: What is the process for adjusting voltage requirements?

A: Customers may specify their required wattage and voltage when ordering. The manufacturer will configure the machine accordingly, ensuring safe and efficient operation under the provided electrical conditions.Q: How does the computerized control system benefit daily operation?

A: Computerized control streamlines daily usage by automating operational settings, monitoring performance, and minimizing manual input. This enhances productivity and improves the overall reliability of the filling process.Q: What are the main advantages of choosing this machine for bulk filling operations?

A: Key benefits include high-speed and simultaneous filling, reduced manpower requirements, robust stainless steel construction, and comprehensive warranty support, making it a valuable asset for businesses focusing on large-scale production.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Liquid Filling Machine Category

Liquid Syrup Filling Machine

Price 300000 INR / Piece

Minimum Order Quantity : 1 Piece

Drive Type : Electric

Computerized : No

Automatic Grade : SemiAutomatic

Control System : Human Machine Interface

Volumetric Linear Bottle Filling Machine

Price 500000 INR / Piece

Minimum Order Quantity : 1 Piece

Drive Type : Electric

Computerized : No

Automatic Grade : Automatic

Control System : Human Machine Interface

Chemical Filling Machine

Price 1600000 INR / Unit

Minimum Order Quantity : 1 Unit

Drive Type : Electric

Computerized : No

Automatic Grade : Automatic

Control System : Human Machine Interface

Automatic Win-e Filling Machine

Price 1500000 INR / Unit

Minimum Order Quantity : 1 Unit

Drive Type : Electric

Computerized : No

Automatic Grade : Automatic

Control System : Human Machine Interface

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free