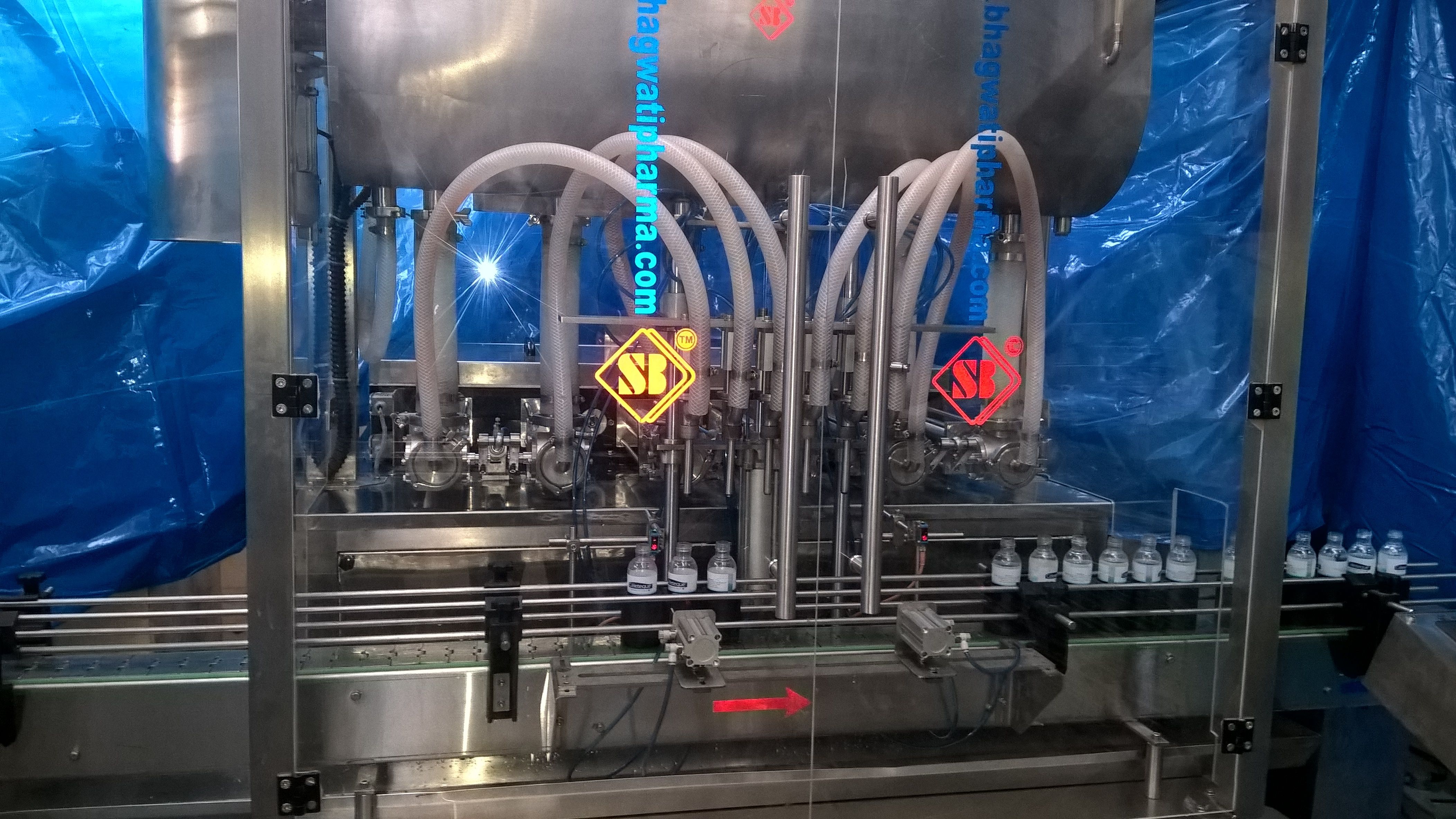

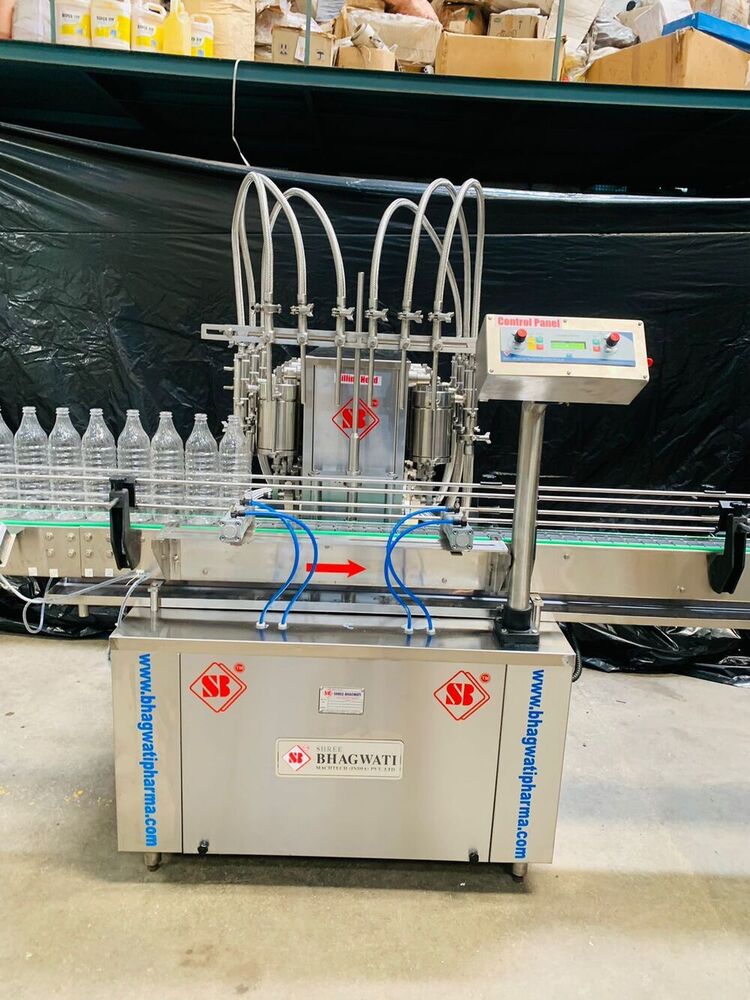

Automatic Honey Filling Machine

Price 500000-2000000 INR/ Unit

Automatic Honey Filling Machine Specification

- Product Type

- Honey Filling Machine

- Material

- SS

- Computerized

- No

- Automatic Grade

- Automatic

- Control System

- Human Machine Interface

- Drive Type

- Electric

- Feature

- ECO Friendly

- Warranty

- 1 Year

Automatic Honey Filling Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Cash Against Delivery (CAD), Cash Advance (CA), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque

- Supply Ability

- 30 Pieces Per Month

- Delivery Time

- 6-8 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Packing Only

- Main Domestic Market

- All India

- Certifications

- CE & ISO Certified

About Automatic Honey Filling Machine

SPECIFICATIONOF THE EQUIPMENT MACHINES BASICS

| PARTICULAR | SPECIFICATION |

| Machine Name | Automatic Piston Liquid Filling Machine |

| Filling System | Servo base filling |

| Production Speed Per Hour | 3200 to 3600 containers per hour Speed Depends upon the Number of Filling Heads, Liquid Foaming Nature, Filling Volume, Neck Size) |

| Number of Filling Heads | 4 Heads |

| Working Direction | Left to Right - Linear |

| Suitable for Products | Free Flowing Liquids |

| Suitable for Packing Material | HDPE / PET / GLASS / METAL TIN / Aluminum Bottles |

| Application | Filling Liquid / Viscous Liquid/ Hot Liquid in to the Bottles /Containers |

| Volume Capacity (Range of Syringe) | 100ml to 1000 ml with help of change parts |

| Hopper Capacity | 200 liters |

| Hopper Specification | Jacketed with stirrer |

| Volume Adjustment | HMI + PLC (one time setting) |

| Prevention of Dropping | Pneumatic system |

| Up Down Movement | Pneumatic system |

| Filling Volume Accuracy | +/-0.5 % |

| Working Height | 860mm ( +/-50 mm) |

| Machine Weight | Approx 450 Kgs |

| Machine Dimension | Approx 8 (L) x 8 (W) x 10 (H)in Feet |

| No Bottle No Filling | With the help of Sensor |

Effortless Operation

This honey filling machine is equipped with a touch screen and simple control system, allowing users to easily set parameters for filling volume and speed. Its automatic grade and electric drive eliminate the need for manual intervention, ensuring consistent and accurate filling every time.

Versatile and Customizable

Designed to handle container sizes from 100 to 1000 ml, the machine accommodates various packaging needs. Customers can request voltage specifications to align with their facility requirements, making it suitable for diverse manufacturing environments across India.

FAQs of Automatic Honey Filling Machine:

Q: How does the automatic honey filling process work?

A: The machine utilizes an electric drive and PLC or Human Machine Interface for precise control. Operators set filling parameters using the touch screen; the system then automatically dispenses honey into containers ranging from 100 to 1000 ml, ensuring uniformity and speed.Q: What benefits does the automatic honey filling machine offer?

A: Key advantages include high efficiency, simple operation, lower energy consumption, low noise, and eco-friendly performance. The stainless steel construction ensures durability and hygiene, while automatic operation improves productivity and reduces labor costs.Q: When is this machine most suitable for use?

A: It is ideal for use in honey production facilities, packaging plants, and distribution centers, especially where large volumes and a variety of container sizes need to be filled with consistency and minimal manual effort.Q: Where can I purchase the automatic honey filling machine in India?

A: The machine is available through distributors, exporters, manufacturers, and suppliers based in India. Interested buyers can contact these businesses to place orders or request customization options.Q: What is the warranty period and what does it cover?

A: The machine comes with a one-year warranty covering manufacturing defects and faulty components. This provides customers with assurance regarding quality and after-sales support for repairs or replacements, if needed.Q: Can the filling capacity and voltage be customized?

A: Yes, the machines filling capacity is adjustable between 100 and 1000 ml, and the voltage can be tailored to match specific customer requirements, ensuring compatibility with various regional standards.Q: Is the honey filling machine environmentally friendly?

A: Absolutely. The machine is designed with lower energy consumption, uses eco-friendly technology, and operates quietly, minimizing its environmental impact while maintaining high performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Liquid Filling Machine Category

Automatic Win-e Filling Machine

Price 1500000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : As per customer requirement Watt (w)

Warranty : 1 Year

Automatic Grade : Automatic

Heating System : Other

4 Head Viscous Lotion Filling Machine

Price 1200000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : As per customer requirement Watt (w)

Warranty : 1 Year

Automatic Grade : Automatic

Heating System : Other

6 Head Volumetric Essential Oil Filling Machine

Price 675000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 220240 Volt (v)

Warranty : 1 Year

Automatic Grade : Automatic

Heating System : Other

Chemical Filling Machine

Price 1600000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : As per customer requirement Watt (w)

Warranty : 1 Year

Automatic Grade : Automatic

Heating System : Other

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free