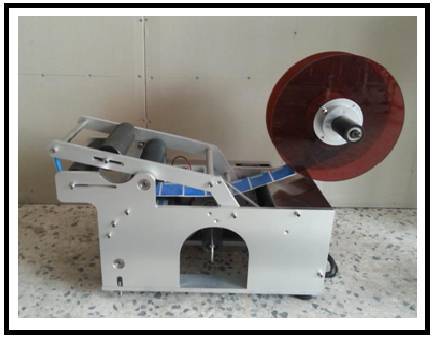

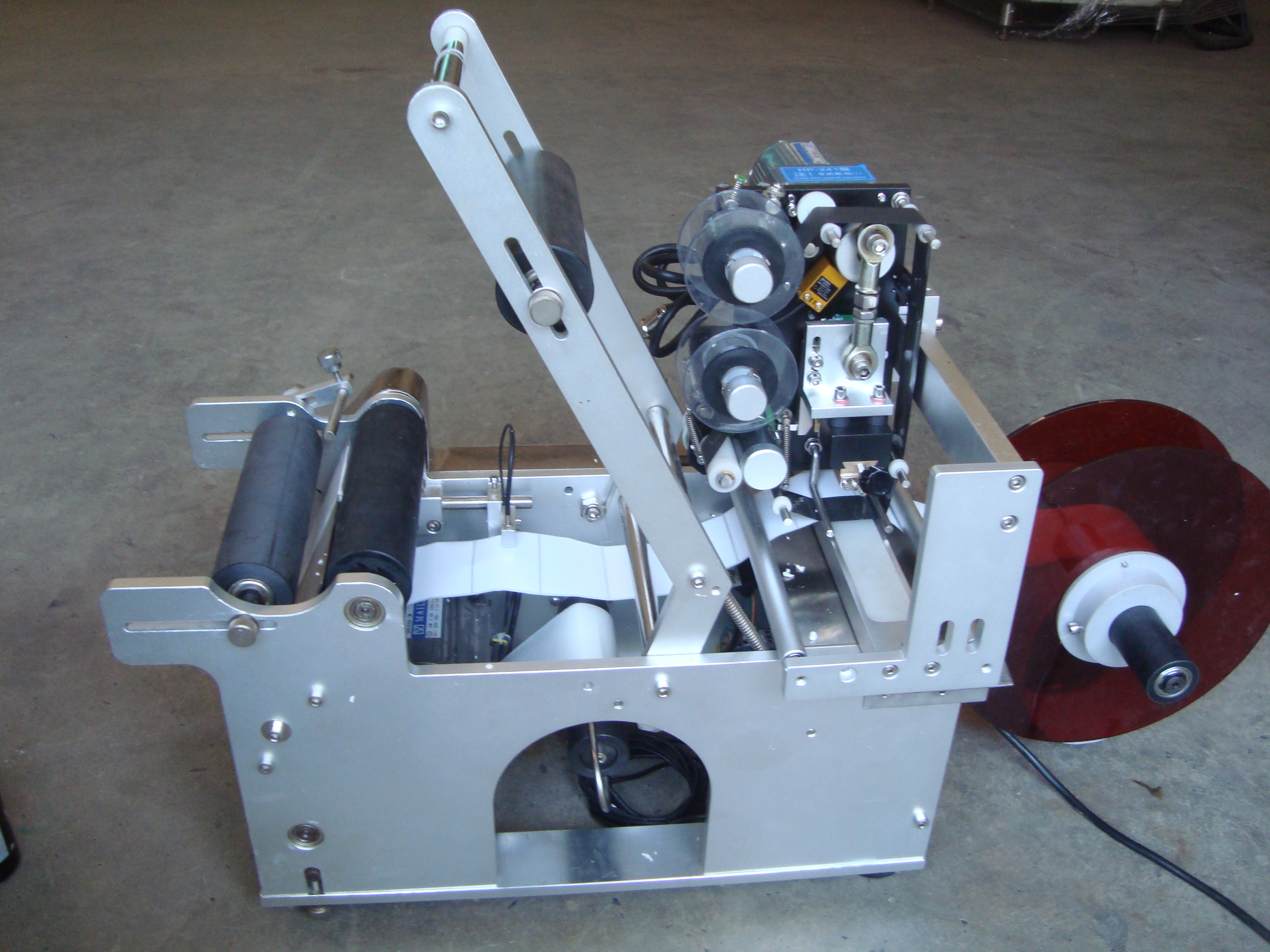

Table Top Sticker Labeling Machine

Price 150000 INR/ Unit

Table Top Sticker Labeling Machine Specification

- Product Type

- Labeling Machine

- Material

- Stainless steel

- Application

- To Stick the labels on Bottles or Jars

- Computerized

- No

- Automatic Grade

- Semi Automatic

- Control System

- Human Machine Interface

- Drive Type

- Mechanical

- Accuracy

- 0.1 mm mm

- Power Source

- Electric

- Voltage

- As per the client required Watt (w)

- Warranty

- 1 year

Table Top Sticker Labeling Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- India

- Supply Ability

- 30 Units Per Week

- Delivery Time

- 4-6 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Packing Only

- Main Export Market(s)

- Australia, North America, Eastern Europe, Western Europe, Middle East, Central America, South America, Asia, Africa

- Main Domestic Market

- All India

- Certifications

- ISO and CE Certified

About Table Top Sticker Labeling Machine

Application

Any type Aluminium, Composite, HDPE, Pet, Tin or Glass bottle Suitable for Pharmaceuticals, Food, Beverage, Distillery, Cosmetics, Pesticides, Chemicals,Agro Chemical and similar products. We have to put the bottle manually on wrapping unit for label application.

Technical Specification

| Bottle size | 15mm to 90mm |

| Output speed | Up to 05 to 08 BPM depend on bottle size |

| Label size ( H x L ) | Min 15 and 250 mm |

| Working Height | Table top |

| Power Consumption | 0.2 KW |

| Power Supply | Single Phase, 230V, 50 Hz |

| Air Supply | 4 to 6 Kg/cm2 |

Efficient Label Application

This semi-automatic machine streamlines the process of applying stickers to bottles and jars, delivering uniform and professional results. The device features adjustable settings for precise labeling, making it suitable for diverse industry requirements. With its compact table-top design, users benefit from ease of installation, operation, and minimal space consumption.

Durable Construction

Manufactured using high-quality stainless steel, the Table Top Sticker Labeling Machine promises longevity even in demanding environments. Its robust build resists corrosion and wear, ensuring reliable performance for heavy-duty operations. Combined with a mechanical drive and electric power source, the machine operates smoothly and efficiently over extended periods.

FAQs of Table Top Sticker Labeling Machine:

Q: How does the Table Top Sticker Labeling Machine operate for labeling bottles or jars?

A: The machine uses a semi-automatic mechanism where operators place bottles or jars on the labeling platform. The Human Machine Interface manages the process, ensuring labels are accurately applied with a precision of 0.1 mm.Q: What are the benefits of using this labeling machine for businesses in India?

A: It offers efficient and consistent label application, increased productivity, and reduced human error. Its robust stainless steel construction ensures long-term reliability, making it suitable for distributors, manufacturers, exporters, and suppliers.Q: When can I expect the machine to be ready for use after installation?

A: Once installed and connected to the appropriate electric power source as per your required voltage specifications, the machine is ready for immediate operation. Basic setup and adjustment can be completed swiftly.Q: Where can this machine be used in the labeling process?

A: It is ideal for table-top operations in packaging lines, factories, small manufacturing units, and export setups where bottles or jars require accurate sticker labels applied quickly and efficiently.Q: What is the process for customizing the voltage of the machine?

A: The voltage of the machine can be tailored to the clients requirements during the order stage. Please specify your desired wattage so the manufacturer or distributor can ensure compatibility with your facilitys power supply.Q: How does the control system enhance user experience during operation?

A: The Human Machine Interface provides straightforward controls for managing labeling functions, making operation intuitive even for users with minimal training. This speeds up the process and minimizes errors.Q: What maintenance is required to ensure the machines optimal performance?

A: Routine cleaning of the stainless steel surfaces, regular mechanical checks, and adherence to operation guidelines are recommended. The manufacturer offers support and a 1-year warranty for added peace of mind.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Label & Sticker Labeling Machine Category

Automatic Sticker labeling machine

Price 5000000 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : Yes

Power Source : Electric

Drive Type : Electric

Automatic Grade : Automatic

Automatic Single Side Flat Sticker Labelling Machine

Price 500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Computerized : Yes

Power Source : Electric

Drive Type : Electric

Automatic Grade : Automatic

Tube Sticker Labelling Machine With Manually Feeding Systems

Price nan INR

Minimum Order Quantity : 1 Piece

Computerized : No

Power Source : Electric

Drive Type : Electric

Automatic Grade : Semi Automatic

Automatic Self Adhesive Vertical Sticker Labelling Machine

Price 300000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Computerized : Yes

Power Source : Electric

Drive Type : Electric

Automatic Grade : Automatic

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free