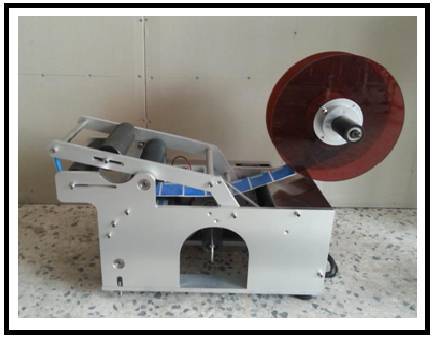

Automatic Single Side Flat Sticker Labelling Machine

Price 500000.00 INR/ Piece

Automatic Single Side Flat Sticker Labelling Machine Specification

- Product Type

- Labeling Machine

- Material

- Stainless steel

- Application

- To Stick the Labels on bottles or Jars

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Control

- Drive Type

- Electric

- Accuracy

- 0.5 mm mm

- Power Source

- Electric

- Voltage

- As per the client required Watt (w)

- Feature

- High Performance, Simple Control, Touch Screen, ECO Friendly, Low Noise, Lower Energy Consumption, High Efficiency

- Warranty

- 1 year

Automatic Single Side Flat Sticker Labelling Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- India

- Supply Ability

- 30 Pieces Per Week

- Delivery Time

- 4 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden packing only

- Main Domestic Market

- All India

- Certifications

- ISO and CE Certified

About Automatic Single Side Flat Sticker Labelling Machine

TechnicalSpecification:

| Type Of Labelling | Single Side Labelling |

| Model | SBSL -120F |

| Speed | Up to 40-50 Labels per minute depending on Product and Label Size. The speed is also depending on stable movement of product on machine conveyor at higher speed. |

| Label Roll Dia. | 300 mm |

| Label accuracy | ±1mm |

| Core Dia. | 75/76 mm |

| Gap Between two Labels | Appx. 3 mm |

| Electrical | 220 VAC Single Phase Power Supply (50/60 Hz) |

| Power | 2.0 Amp. |

| Conveyor height | 830-875 mm* |

| Machine Direction of Movement | Left to Right from operator side |

Advanced Control Technology for Seamless Operation

Equipped with computerized PLC control and a responsive touch screen, the machine ensures straightforward operation and real-time process monitoring. Users can easily adjust settings for various labelling requirements, ensuring consistent and high-quality results every time.

Precision and Efficiency for Modern Manufacturing Needs

This labelling machine delivers exceptional accuracy (0.5 mm), high-speed performance, and optimal energy efficiency. Its robust stainless steel construction supports long-term use, while low-noise and eco-friendly features cater to environmentally conscious businesses.

FAQs of Automatic Single Side Flat Sticker Labelling Machine:

Q: How does the Automatic Single Side Flat Sticker Labelling Machine enhance labelling accuracy?

A: This machine utilizes computerized PLC control and advanced sensors to achieve a consistent labelling accuracy of 0.5 mm, ensuring each label is perfectly positioned on bottles or jars.Q: What is the process for installing and operating the labelling machine?

A: Installation is guided by manufacturer instructions, including electric connection based on client voltage requirements. Operation is simplified through a touch screen and PLC control system, allowing users to set parameters and begin automatic labelling swiftly.Q: When is preventive maintenance recommended for the machine?

A: Preventive maintenance is advised at regular intervals, ideally once every few months, to check components, clean sensors, and ensure the touch screen and PLC system function efficiently. This upkeep helps maintain high performance and prolongs machine lifespan.Q: Where can this labelling machine be used effectively?

A: The machine is suitable for use in manufacturing plants, packaging facilities, bottling lines, and jar labelling applications. Its compact design and electric drive make it adaptable to various industrial environments.Q: What benefits does the machine provide for energy and operational efficiency?

A: Thanks to its lower energy consumption features and eco-friendly design, the machine reduces operational costs, supports sustainable practices, and enhances productivity with high-speed labelling capabilities.Q: Can the machines voltage and settings be customized for specific client needs?

A: Yes, the voltage specifications and control settings can be tailored to match individual client requirements, ensuring compatibility with different factory setups across India.Q: What warranty and support services are available for this labelling machine?

A: The machine comes with a 1-year warranty, covering manufacturing defects and providing dedicated support from the supplier, exporter, distributor, and manufacturer network within India.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Label & Sticker Labeling Machine Category

Automatic Sticker labeling machine

Price 5000000 INR / Unit

Minimum Order Quantity : 1 Unit

Power Source : Electric

Material : Stainless Steel

Automatic Grade : Automatic

Warranty : 1 Year

Multi Function Oil Bottle Labeling Machine

Minimum Order Quantity : 1 Piece

Power Source : Electric

Material : Stainless Steel

Automatic Grade : Automatic

Warranty : 1 year

Table Top Sticker Labeling Machine

Price 150000 INR / Unit

Minimum Order Quantity : 1 Unit

Power Source : Electric

Material : Stainless steel

Automatic Grade : Semi Automatic

Warranty : 1 year

Automatic Horizontal Top Sticker Labelling Machine

Price 400000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Power Source : Electric

Material : Stainless steel

Automatic Grade : Automatic

Warranty : 1 Year

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free