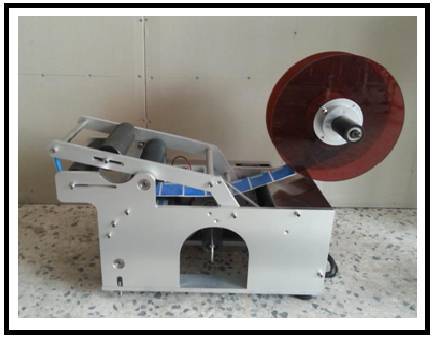

Automatic Sticker labeling machine

Price 5000000 INR/ Unit

MOQ : 1 Unit

Automatic Sticker labeling machine Specification

- Product Type

- Labeling Machine

- Material

- Stainless Steel

- Application

- To stick on Bottles or jars

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Control

- Drive Type

- Electric

- Accuracy

- +/- 0.5 mm mm

- Power Source

- Electric

- Voltage

- As per the client required Volt (v)

- Weight (kg)

- In kgs Kilograms (kg)

- Dimension (L*W*H)

- In Inches Inch (in)

- Capacity

- Up to 80-100 BPM Kg/day

- Feature

- High Performance, Lower Energy Consumption, Touch Screen, Simple Control, ECO Friendly, Low Noise, High Efficiency

- Color

- Other

- Warranty

- 1 Year

Automatic Sticker labeling machine Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- India

- Supply Ability

- 30 Units Per Week

- Delivery Time

- 4 -6 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden packing only.

- Main Export Market(s)

- Australia, Eastern Europe, Western Europe, Middle East, Central America, Africa, South America, Asia, North America

- Main Domestic Market

- All India

- Certifications

- ISO and CE Certified

About Automatic Sticker labeling machine

Features:-- No change parts for container and label size in standard shaped containers

- Single Point on-line Speed Variation control system

- Precise Label Placement Accuracy

- Built In A.C. Freq. Drive System

- Output up to 150 labels per minute.

- Fully Stainless Steel Finish including main machine frame

- Optionally online coding system

Seamless Labeling with Maximum Efficiency

Our automatic sticker labeling machine combines swift operation with unmatched efficiency. Designed to process up to 100 bottles or jars per minute, it ensures your production line runs smoothly. The simple control interface enables quick setup and changeover, reducing downtime and increasing productivity for manufacturers and suppliers alike.

Precision and Sustainability Built-In

Enjoy accurate labeling with a precision of 0.5 mm, reducing material waste and ensuring product consistency. The energy-efficient motor and eco-friendly design minimize operational costs while supporting sustainable practices. Low noise output and stainless steel construction make this machine durable and suitable for demanding environments.

Touch Screen Ease and Flexible Control

User convenience is elevated by a sophisticated touch screen display and PLC-based control system. Operators can easily adjust settings and monitor processes in real-time, resulting in fewer errors and higher quality output. Voltage requirements and machine dimensions can be tailored to your specific needs, offering versatile integration into diverse production setups.

FAQs of Automatic Sticker labeling machine:

Q: How does the automatic sticker labeling machine enhance labeling accuracy?

A: The machine uses a computerized PLC control system and precise mechanisms to achieve accuracy of 0.5 mm, ensuring uniform placement of stickers on bottles or jars. This minimizes labeling errors and enhances the professional look of your products.Q: What types of containers can this machine label?

A: It is specifically designed for bottles and jars, making it suitable for a wide range of industries, including food, beverage, and pharmaceuticals. The adjustable features allow it to accommodate different sizes and shapes.Q: When should I perform routine maintenance for the machine?

A: Routine maintenance should be conducted as recommended in the user manual, typically after a set number of operational hours or daily, depending on the intensity of use. Regular checks ensure optimal performance and help to prolong the machines lifespan.Q: Where can this machine be utilized?

A: The automatic sticker labeling machine is ideal for integration within manufacturing plants, bottling facilities, and packaging centers. Its robust stainless steel design ensures reliability in industrial environments across India and beyond.Q: What is the process for setting up and operating the machine?

A: To operate, simply connect the electric power as per your voltage requirements, use the touch screen to configure settings, load label rolls and bottles, and the machine automates the sticking process. The PLC control and interface guide operators through setup and usage.Q: What are the benefits of using an eco-friendly sticker labeling machine?

A: This machines eco-friendly design ensures lower energy consumption and reduced noise, supporting sustainable manufacturing practices while cutting down on operational expenses and environmental impact.Q: How does the warranty coverage work?

A: The machine comes with a 1-year warranty covering manufacturing defects and certain parts. Service and support are provided by the supplier or manufacturer, ensuring peace of mind and prompt assistance if issues arise.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Label & Sticker Labeling Machine Category

Multi Function Oil Bottle Labeling Machine

Minimum Order Quantity : 1 Piece

Computerized : Yes

Material : Stainless Steel

Drive Type : Electric

Automatic Grade : Automatic

Automatic Single Side Flat Sticker Labelling Machine

Price 500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Computerized : Yes

Material : Stainless steel

Drive Type : Electric

Automatic Grade : Automatic

Table Top Sticker Labeling Machine

Price 150000 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : No

Material : Stainless steel

Drive Type : Mechanical

Automatic Grade : Semi Automatic

Tube Sticker Labelling Machine With Manually Feeding Systems

Price nan INR

Minimum Order Quantity : 1 Piece

Computerized : No

Material : Stainless steel

Drive Type : Electric

Automatic Grade : Semi Automatic

Let's talk business

Please take a moment to complete this form and a business representative will get back to you swiftly

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free