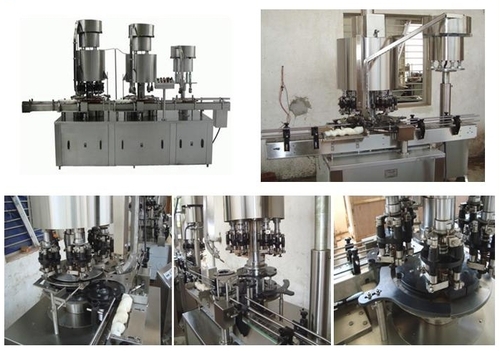

Two Head Rotary Servo Capping Machine

Two Head Rotary Servo Capping Machine Specification

- Type

- Capping Machines

- Material

- Stainless steel

- Feature

- Other

- Auxiliary Packaging Machine Type

- Other

- Capacity

- Up to 35-40 BPM. Kg/hr

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Control

- Drive Type

- Electric

- Power

- As per the client required Watt (w)

- Voltage

- As per the client required Watt (w)

- Weight (kg)

- As per the client required Kilograms (kg)

- Dimension (L*W*H)

- In inches Inch (in)

- Color

- Other

- Warranty

- 1 year

Two Head Rotary Servo Capping Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- India

- Supply Ability

- 30 Pieces Per Week

- Delivery Time

- 4-6 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden box packing

- Main Domestic Market

- All India

- Certifications

- ISO and CE Certified

About Two Head Rotary Servo Capping Machine

Features:-

- PLC based controlled panel.

- Operating Modes Auto & Manual.

- Easily alter the capping chuck according to the bottle cap size.

- For perfect capping Servo Motors is used so that with a required torque capping of bottles are done.v The Variable Frequency Drive allows setting the appropriate speed of the conveyor to synchronize the machine operation according to the bottle size/volume.

- No cap no feeding.

- Input Supply 230VAC, Max 400 Watt.

- Air Consumption 3CFM at 6 bar only.

Product Details:

| Automation Grade | Automatic |

| Frequency | 50 Hz |

| Voltage | 240 V |

| Capping Speed | Up to 35-40 BPM. |

| Air Consumption | 4-5 CFM at 6 Bar. |

| Power Source | Electric |

| Material | SS-304 / SS-316 |

| Power Consumption | 1 KW |

Advanced Servo Technology

Equipped with state-of-the-art rotary servo motors, this capping machine provides superior torque accuracy and smooth, reliable operation. The technology ensures fast cycle times and consistent sealing, minimizing downtime and maintaining product integrity. Operators benefit from reduced maintenance thanks to robust stainless steel construction and precision engineering.

User-Friendly Automated Features

The automatic grade and computerized controls simplify operation, allowing for seamless adjustments and monitoring through a dedicated PLC control system. This automation reduces human intervention, enhances productivity, and supports flexible configurations based on specific project requirements, including custom weight, voltage, dimensions, and power settings.

Customizable for Industry Needs

Manufacturers, distributors, exporters, and suppliers in India can tailor the machines specifications for weight, dimensions, voltage, and capacity. This capping machine is ideal for diverse applications, handling various bottle sizes and closure types with ease. Designed to integrate smoothly into existing production setups, it improves efficiency and adapts to changing business demands.

FAQs of Two Head Rotary Servo Capping Machine:

Q: How does the Two Head Rotary Servo Capping Machine optimize the capping process?

A: The machine utilizes dual servo motors with rotary heads, controlled by a PLC system, enabling fast and accurate tightening of caps. Automation reduces manual labor and standardizes output, ensuring each bottle is sealed securely and consistently.Q: What materials are used in the construction of this capping machine?

A: This capping machine is constructed using premium stainless steel, which offers corrosion resistance and long-term durability. Its robust structure ensures reliable performance even in rigorous industrial environments.Q: When should I consider using this automatic capping machine in my production line?

A: It is ideal for when you require efficient, high-volume capping operations and need to improve throughput up to 35-40 bottles per minute. Integration is recommended during upgrades, expansions, or when automating manual sealing processes.Q: Where is the Two Head Rotary Servo Capping Machine available for purchase?

A: The machine is available through authorized distributors, exporters, manufacturers, and suppliers across India. Customers can contact the supplier directly to discuss customization, installation, and support requirements.Q: What benefits does the PLC control system offer for machine operation?

A: The PLC control system provides precise command over all capping parameters, allowing for efficient changeover, error monitoring, and real-time adjustments. It enhances consistency, reduces the risk of operational errors, and simplifies maintenance.Q: How can the specifications be customized to meet my business needs?

A: Clients can specify their desired weight, voltage, power, and dimensions when placing an order to ensure the machine meets unique production requirements. This customization helps the equipment fit seamlessly into various manufacturing setups.Q: What warranty and after-sales support are included with this machine?

A: The Two Head Rotary Servo Capping Machine comes with a one-year warranty, covering manufacturing defects and operational issues. Technical support and maintenance assistance are available to ensure uninterrupted operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Capping Machine Category

Multi Head Linear Capping Machine - Three Head

Minimum Order Quantity : 1 Piece

Material : Stainless steel

Automatic Grade : Automatic

Computerized : Yes

Drive Type : Electric

8 Head Ropp Capping Machine

Price 1180000 INR / Number

Minimum Order Quantity : 1 Number

Material : Stainless Steel (SS 304/316)

Automatic Grade : Automatic

Computerized : Yes

Drive Type : Other, Electric Motor (Synchronized with Conveyor)

Muti Head ROPP Capping machine

Price 1500000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : SS

Automatic Grade : Automatic

Computerized : No

Drive Type : Electric

12 Head Aluminium vial Cap Sealing Machine

Price 1800000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : SS

Automatic Grade : Automatic

Computerized : No

Drive Type : Electric

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free