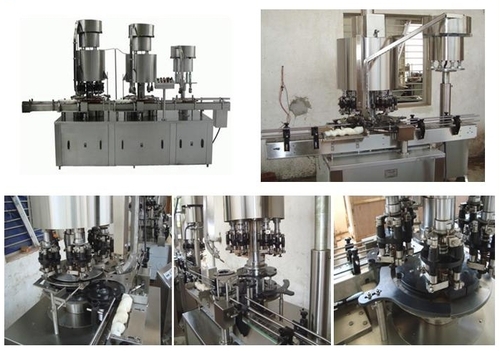

8 Head Ropp Capping Machine

Price 1180000 INR/ Number

MOQ : 1 Number

8 Head Ropp Capping Machine Specification

- Noise Level

- 75 dB db

- Application

- Pharmaceutical, Food & Beverage, Chemical, Cosmetic Packaging

- Power Supply

- 3 Phase, 50/60 Hz

- Filling Range

- Applicable for Bottle Cap Sizes: 18mm-38mm

- Usage

- Bottle capping in production lines

- Features

- High Speed, Accurate Torque, Low Maintenance

- Type

- 8 Head Ropp Capping Machine

- Material

- Stainless Steel (SS 304/316)

- Feature

- Other

- Auxiliary Packaging Machine Type

- Automatic Capping Machine

- Computerized

- Yes

- Automatic Grade

- Automatic

- Drive Type

- Electric Motor (Synchronized with Conveyor)

- Power

- 2-3 HP Horsepower (HP)

- Voltage

- 220-440V AC, 3 Phase Volt (v)

- Weight (kg)

- Approx. 750-900 kg Kilograms (kg)

- Dimension (L*W*H)

- 2200 mm x 900 mm x 1800 mm Millimeter (mm)

- Color

- Metallic Silver / Customized

- Sealing Type

- ROPP (Roll On Pilfer Proof)

- Lubrication

- Centralized Automatic Lubrication System

- Construction

- GMP Model, SS Cladding on base frame

- Bottle Diameter Range

- 25-85 mm

- Bottle Height Range

- 50-300 mm

- Cap Feeding System

- Automatic with Elevator

- Output Per Hour

- Up to 7,200 Bottles

- Operational Mode

- Continuous, Intermittent

- Conveyor Height

- Adjustable, 800-850 mm

- Safety Features

- Emergency Stop, Overload Protection

- Changeover Time

- Quick Change Parts for Fast Changeover

8 Head Ropp Capping Machine Trade Information

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 1000 Per Month

- Delivery Time

- 7 Days

About 8 Head Ropp Capping Machine

Automatic ROPP cap sealing machine is versatile,self-supported on stainless steel leg with height adjustable adjustment system.The machine is precision built on sturdy welded steel frame completely enclosein stainless steel sheet and doors are provided to facilitate the servicing ofmachineHigh-Speed Output and Versatility

This 8 head ROPP capping machine supports capacities of 80120 bottles per minute, with an hourly output of up to 7,200 bottles. Its adjustable conveyor height and bottle diameter range (2585 mm) allow for quick adaptation to varying bottle sizes and types, making it suitable for multiple industries such as pharmaceuticals and cosmetics.

Advanced Safety and Control Systems

Equipped with safety features such as emergency stop, overload protection, safety guard, and a no bottle-no cap system, this machine ensures operator safety and product integrity. Its PLC-based control panel offers computerized precision and easy monitoring of operational parameters.

Quick Changeover and Automated Cap Feeding

The machine maximizes production time thanks to fast change parts and an automatic cap feeding system. The elevator mechanism streamlines cap supply, while quick changeover reduces downtime when switching between different bottle or cap specifications.

Robust GMP Construction for Hygiene and Durability

Crafted from SS 304/316 and designed following GMP standards, the machine features SS cladding on its base frame, ensuring a hygienic environment for sensitive products. Its vibration-free operation, centralized lubrication, and sturdy build facilitate prolonged, reliable use in demanding production lines.

Noise, Power, and Efficiency

Delivering high speed performance with a noise level below 75 dB, the machine operates efficiently on 23 HP and a 3-phase, 220440V AC power supply. Synchronized electric motors ensure smooth cap application every cycle, regardless of production mode: continuous or intermittent.

FAQs of 8 Head Ropp Capping Machine:

Q: How does the automatic cap feeding system with elevator benefit production efficiency?

A: The automatic cap feeding system uses an elevator to continuously supply caps to the capping heads, minimizing manual intervention and reducing downtime. This streamlines the capping process, boosts productivity, and supports uninterrupted high-speed operations.Q: What is the process for changing over to different bottle or cap sizes on this machine?

A: Changeover is expedited with quick change parts, requiring minimal manual adjustments. Operators can switch to different bottle diameters (2585 mm), heights (50300 mm), or cap sizes (1838 mm) rapidly, enabling efficient batch processing and minimizing production halts.Q: Where is this machine typically used in packaging operations?

A: This automatic capping machine is commonly utilized in the pharmaceutical, food & beverage, chemical, and cosmetic sectors. It is deployed in production lines where precise, high-speed bottle capping and consistent product sealing are critical for safety and quality assurance.Q: What safety mechanisms are incorporated in the machines design?

A: The machine includes emergency stop features, overload protection, a safety guard, and a no bottle-no cap system that prevents accidental operation, safeguarding both personnel and products throughout the packaging process.Q: How is maintenance managed and what are the noise levels during operation?

A: Maintenance is simplified with a centralized automatic lubrication system, extending the lifespan of key moving parts and reducing manual intervention. The operation is vibration free with noise levels under 75 dB, promoting a safe and comfortable working environment.Q: What are the key benefits of using this machine for large-scale bottle capping?

A: Users benefit from high speed, accurate torque application, reliable ROPP sealing, low maintenance requirements, and computerized control for consistent results. The robust GMP construction ensures suitability for regulated industries and long-term durability.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Capping Machine Category

Single Head Screw Capping Machine

Price 450000 INR / Number

Minimum Order Quantity : 1 Number

Automatic Grade : Automatic

Drive Type : Electric

Computerized : Yes

Material : Stainless Steel

Automatic Single Head Crown Capping Machine

Minimum Order Quantity : 1 Piece

Automatic Grade : Automatic

Drive Type : Electric

Computerized : Yes

Material : Stainless steel

Automatic Screw Capping Machine

Price 400000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Drive Type : Electric

Computerized : Yes

Material : stainless steel

Muti Head ROPP Capping machine

Price 1500000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Drive Type : Electric

Computerized : No

Material : SS

Let's talk business

Please take a moment to complete this form and a business representative will get back to you swiftly

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS