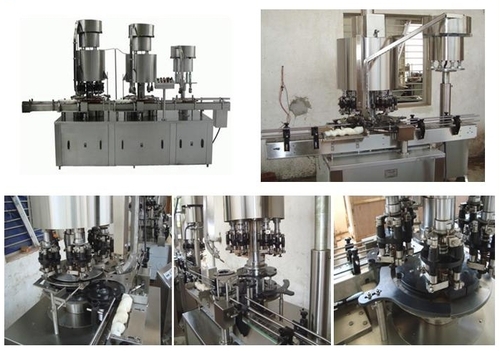

Muti Head ROPP Capping machine

Price 1500000 INR/ Unit

Muti Head ROPP Capping machine Specification

- Features

- Good Quality

- Usage

- Industrial

- Material

- SS

- Computerized

- No

- Automatic Grade

- Automatic

- Control System

- Human Machine Interface

- Drive Type

- Electric

- Color

- Silver

- Warranty

- 1 Year

Muti Head ROPP Capping machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 30 Units Per Month

- Delivery Time

- 8 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Packing Only

- Main Domestic Market

- All India

- Certifications

- CE & ISO Certified

About Muti Head ROPP Capping machine

Muti Head Capping machine Four , Six , Eight Ropp Cap Sealing Machine

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| * Depends on size, shape and Neck Dia of container, Fill volume and nature of liquid etc. * Note : With the help of the change parts. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Efficiency Industrial Capping

Capable of processing between 30 and 300 bottles per minute, the Multi Head ROPP Capping Machine is engineered for businesses requiring reliable output. Its robust stainless steel build and electric drive system ensure operational stability and a long service lifespan, making it ideal for use in large manufacturing plants.

Advanced Automation and Control

This machine features a sophisticated Human Machine Interface (HMI) and PLC Control system, letting operators manage settings with ease and precision. Automatic grade functionality reduces the need for manual intervention, increasing safety and ensuring consistent, secure capping performance throughout production cycles.

Customizable to Fit Your Operations

With voltage and warranty options customizable as per customer requirements, this capping machine seamlessly integrates into various industrial setups. As a distributor, exporter, manufacturer, and supplier based in India, we guarantee flexible solutions to meet the unique needs of your bottling or packaging line.

FAQs of Muti Head ROPP Capping machine:

Q: How does the Multi Head ROPP Capping Machine operate in an automated production line?

A: The machine utilizes advanced PLC controls and a Human Machine Interface (HMI) to automate the capping process. Bottles move through the machine, where multiple heads simultaneously cap them, ensuring speed and uniformity with minimal operator intervention.Q: What types of bottles or caps can this machine handle?

A: This machine is versatile and designed primarily for ROPP (Roll-on Pilfer Proof) caps, commonly used in the pharmaceutical, beverage, and food industries. It can accommodate various bottle sizes and specifications within the stated capacity range.Q: When should I consider using a Multi Head ROPP Capping Machine for my facility?

A: If your production line requires capping speeds of 30 to 300 bottles per minute, or you need to improve operational efficiency and consistency, this automatic capping machine would be a suitable investment to streamline your processes.Q: Where is the Multi Head ROPP Capping Machine manufactured and supported?

A: The machine is manufactured, exported, and supplied from India. Support and customization services are available to match customer-specific requirements for voltage and warranty terms.Q: What is the process for integrating this machine into an existing bottling line?

A: Integration begins with assessing your current lines requirements. The machine is then configuredcapacity, voltage, and control systems adjusted to fit your setupbefore being installed and tested for seamless operation alongside your other equipment.Q: How does the electric drive and stainless steel construction benefit users?

A: The electric drive provides smooth, consistent power for high-speed operation, while the stainless steel construction ensures robust durability, resistance to corrosion, and ease of cleaningmaking it highly suitable for industrial environments.Q: What warranty and after-sales support options are available?

A: A one-year warranty is provided as standard, with customization available as per customer requirements. Comprehensive after-sales support ensures reliability and peace of mind for industrial users.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Capping Machine Category

Multi Head Linear Capping Machine - Three Head

Minimum Order Quantity : 1 Piece

Material : Stainless steel

Automatic Grade : Automatic

Computerized : Yes

Voltage : As per the client required Watt (w)

Two Head Rotary Servo Capping Machine

Minimum Order Quantity : 1 Piece

Material : Stainless steel

Automatic Grade : Automatic

Computerized : Yes

Voltage : As per the client required Watt (w)

Semi Automatic Single Head Screw Capping Machine

Price 110000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Stainless Steel

Automatic Grade : SemiAutomatic

Computerized : No

Voltage : As per the client required Watt (w)

12 Head vial Cap Sealing Machine

Price 3000000 INR / Unit

Minimum Order Quantity : 1 Piece

Material : SS

Automatic Grade : Automatic

Computerized : No

Voltage : 220415 Volt (v)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS