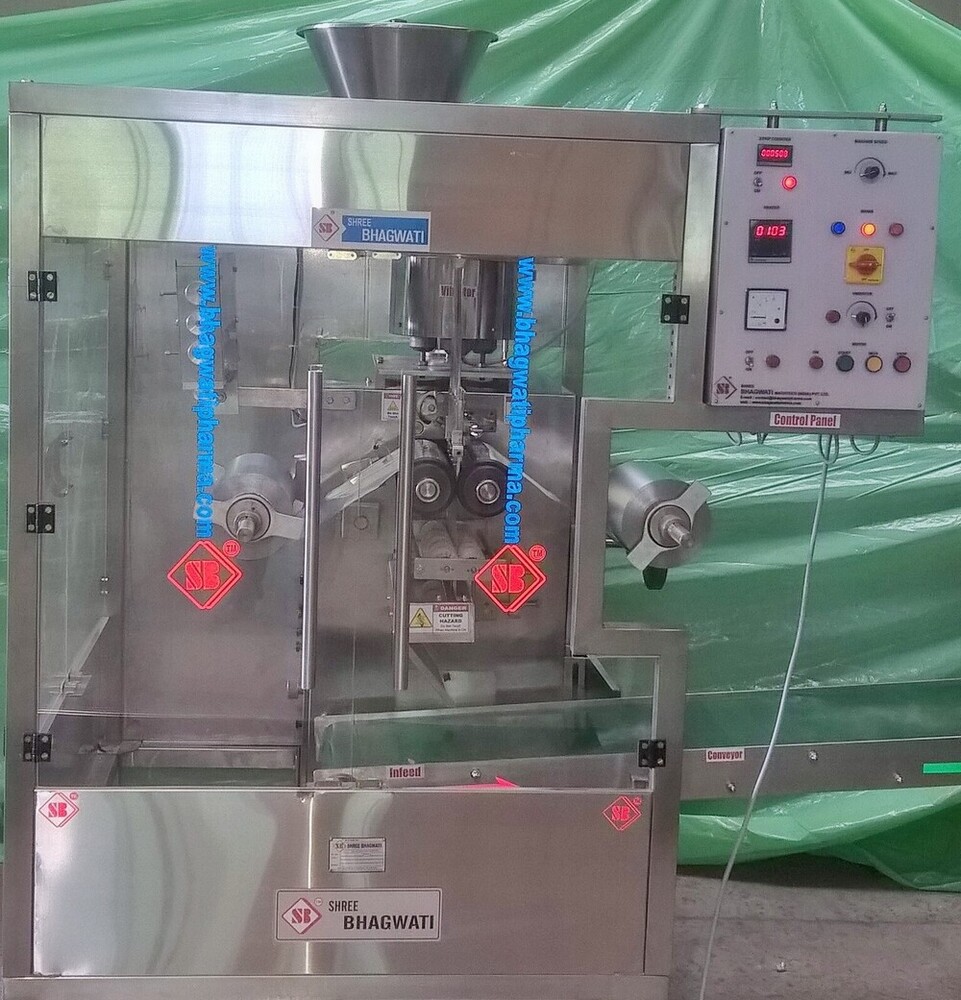

Strip Packing Machine

MOQ : 1 Unit

Strip Packing Machine Specification

- Type

- Blister Packaging Machines

- Material

- Stainless steel

- Auxiliary Packaging Machine Type

- Other

- Capacity

- 30-300 Kg/hr

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Control

- Drive Type

- Electric

- Power

- As per customer requirement Watt (w)

- Voltage

- Single & Three Phase Watt (w)

- Color

- Other

- Warranty

- 1 Year warranty

Strip Packing Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 30 Units Per Month

- Delivery Time

- 8 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Packing Only

- Main Domestic Market

- All India

- Certifications

- CE & ISO Certified

About Strip Packing Machine

We are a leading firm engaged in manufacturing and supplying Strip Packing Machine which is highly reliable for industrial applications.It is installed in various industries for packing of different types of material.Owing to its high efficiency and excellent performance for longer time, offered product is highly acclaimed by the patrons. Our engineers manufactured the Strip Packing Machine following our sophisticated TQM policy. Moreover, we are making this product available at market leading price range.Our esteemed customers can purchase a qualitative range of Strip Packing Machines from us at very cost effective prices in different standard as well as customized specifications as per demands. The offered machines are carefully designed and developed by making use of finest quality raw materials with the help of latest tools and technology, and having large number of striking features that ensure their optimum performance for longer period of time.

Attributes of our Strip Packing Machines -:

Contact parts are as per AISI 316 while the non-contact parts are AISI 304

Standardized parts which are quickly interchangeable

Adjustable slitting device as well as foil cutting

Noiseless, hassle-free and smooth operation

Knurl design

Cavity shape of choice

Gives air tight leak-proof packing

Highly suitable for most heat seal able foils such as Paper Poly, Aluminum Poly, Cellophane, Glassine Poly and Cello Poly

Cartridge type heaters as well as thermostatic temperature control which is suitable for all kinds of packing material

Available in different models of 2, 4, 6, 8, 10 and 12 Tract

Capacity from 400 to 3000 tablet minimum

Maximum sealing width of 250 mm

Body is manufactured with steel and has adequate inspection windows

Vibratory feed control to give higher output

Advanced Stainless Steel Construction

Built entirely from top-grade stainless steel, our Strip Packing Machine guarantees durability and easy cleaning, ideal for industries that demand strict hygiene. The robust construction resists corrosion, extends the machines life, and fits perfectly in pharmaceutical, food, and other high-standard manufacturing environments.

Efficient and Flexible Operation

The automatic operation with PLC control enables precise and efficient blister packaging. Our machine supports both single and three-phase electric sources, tailored as per your voltage requirements, and delivers reliable output from 30 to 300 Kg/hr. This flexibility makes it suitable for projects of all sizes.

Comprehensive Service Across India

As a distributor, exporter, manufacturer, and supplier, we provide full support and service throughout India. Each Strip Packing Machine is backed by a one-year warranty, ensuring customer confidence and continuous production with minimal disruption.

FAQs of Strip Packing Machine:

Q: How does the PLC control system enhance the strip packing process?

A: The PLC control system automates key functions, ensuring precise, consistent operations and reducing human error. This increases packing efficiency and product quality, making the strip packing process more reliable and easier to manage.Q: What materials is the Strip Packing Machine made from?

A: This machine is constructed entirely from stainless steel, making it durable, corrosion-resistant, and suitable for environments where hygiene is critical, such as pharmaceutical and food processing industries.Q: When is the best time to choose a single-phase or three-phase voltage option?

A: Select the single-phase option for smaller installations with lower power requirements, while the three-phase option is recommended for heavy-duty, high-capacity operations. We customize voltage as per your sites specific needs.Q: Where can this automatic Strip Packing Machine be installed?

A: Our machine is versatile and can be installed in pharmaceutical units, food processing plants, and other manufacturing facilities throughout India, thanks to its robust design and customizable power configurations.Q: What is the process for packaging with this machine?

A: The automatic strip packing process involves placing products on the infeed section, with the PLC-controlled machine forming, filling, and sealing blister packs efficiently and hygienically.Q: What are the main benefits of using a computerized Strip Packing Machine?

A: Using a computerized machine streamlines production, ensures consistent quality, reduces errors, minimizes manual intervention, and delivers higher output within a shorter time frame.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Capsule and Tablets Blister Packing Machine Category

Blister Packing Machine

Price 410000 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : No

Control System : PLC Control

Automatic Grade : Automatic

Warranty : 1 Year

Blister Packing machine

Price 410000 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : No

Control System : PLC Control

Automatic Grade : Automatic

Warranty : 1 Year

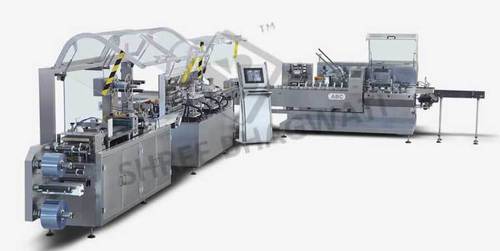

Blister Packing Machines

Price 900000 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : No

Control System : Human Machine Interface

Automatic Grade : Automatic

Warranty : 1 Year

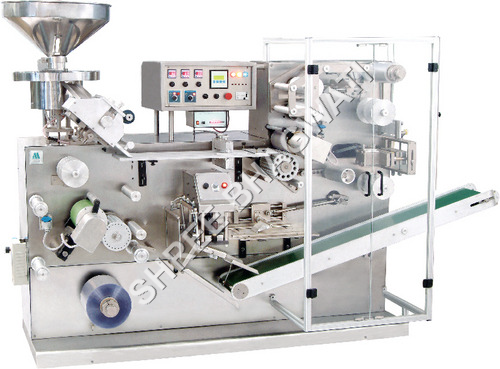

PVC Blister Packing Machine

Price 450000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : Yes

Control System : PLC Control

Automatic Grade : SemiAutomatic

Warranty : yes

Let's talk business

Please take a moment to complete this form and a business representative will get back to you swiftly

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS