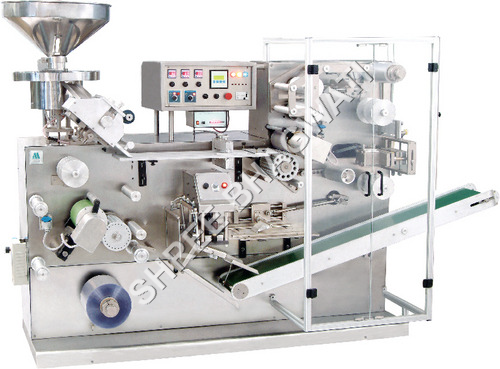

Blister Packing Machine

Price 410000 INR/ Unit

MOQ : 1 Unit

Blister Packing Machine Specification

- Usage

- Industrial

- Power Supply

- Electric

- Material

- Mild steel

- Feature

- Highly Efficient, Durable

- Computerized

- No

- Automatic Grade

- Automatic

- Control System

- PLC Control

- Voltage

- 415 Volt (v)

- Color

- White

- Warranty

- 1 Year

Blister Packing Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- India

- Supply Ability

- 30 Units Per Week

- Delivery Time

- 8-10 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box Packing Only

- Main Domestic Market

- All India

- Certifications

- ISO and CE Certified

About Blister Packing Machine

Salient Features:-

- Max Machine Speed (Packs):- 240 Packs / min

- Max Forming Area:- 110mm x 200mm

- Min Forming Area:- 30mm x 200mm

- Optimum Forming Depth:- 10mm

- Max Reel diameter :- 440mm

- Max Lidding Foil:- 206mm

- Max Core diameter:- 76mm

- Utilities:-Connected Load (kw) 8 kw

- Average Power consumption:- 415 V+- 10% (Apx) Supply 50 Hz, 3 phase 4 wire + Earth

- Cooling Water consumption:- 120 ltrs/Hr

- Compressed Air:- 8 cfm

- Net weight approx:- 1400 kg

- Floor Space:-Machine Width (950 mm) X Machine Height (1820 mm) X Machine Length (2220 mm)

Precision Engineering for Reliable Packaging

Constructed from high-quality stainless steel, the Blister Packing Machine ensures longevity and resistance to corrosion, ideal for pharmaceutical production environments. Its automatic operation minimizes manual intervention, enhancing productivity and packaging consistency. The versatile design can accommodate various capacity, voltage, and power specifications as per client needs, making it an adaptable choice for businesses of different scales.

Customizable to Client Specifications

Whether you require specific dimensions or power settings, our machine is tailored to match your unique requirements. This level of customization allows for seamless integration into existing production lines and ensures optimal performance. Distributed and exported from India, our machines are supported by robust after-sales service and a comprehensive one-year warranty.

FAQs of Blister Packing Machine:

Q: How does the Blister Packing Machine enhance pharmaceutical packaging efficiency?

A: The machine automates the packaging process, significantly reducing manual labor and minimizing the chances of human error. Its computerized controls and customizable capacity allow for rapid, consistent, and hygienic blister packaging, which improves overall operational throughput.Q: What materials and specifications make this machine suitable for the pharmaceutical industry?

A: This packaging machine is constructed with stainless steel, ensuring it meets hygiene and durability standards required in pharmaceutical environments. Its customizable features, such as voltage, power, capacity, and size, ensure compatibility with a wide range of production needs.Q: When will I receive technical support or warranty service if needed?

A: Technical support and warranty services are available throughout the one-year warranty period. Our support team can be reached for troubleshooting, maintenance, or repair needs to ensure continuous and reliable operation of your machine.Q: Where can I install the Blister Packing Machine, and what space considerations are required?

A: The machines dimensions can be specified during ordering to fit your facilitys space. As a result, it can be installed in various production settings, provided theres adequate space and access to the required power supply as specified per client order.Q: What is the process for ordering and customizing the machine to my requirements?

A: To order, simply contact us with your desired specificationssuch as required output capacity, voltage, power, and preferred dimensions. Our team will guide you through selecting the best configuration and coordinate manufacturing, delivery, and installation support.Q: How do I operate and maintain the automatic blister packing machine?

A: Operation requires basic training due to its computerized, automatic interface. Initial training and support are provided post-installation. Routine maintenance involves standard cleaning and periodic checks, which are straightforward thanks to the machines accessible design.Q: What benefits do I gain from using this machine as a distributor, exporter, or manufacturer in India?

A: Utilizing this machine enables faster, quality-consistent pharmaceutical packaging, essential for meeting domestic and international standards. The one-year warranty, customization options, and accessible support ensure a reliable investment for businesses in India.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Capsule and Tablets Blister Packing Machine Category

Blister Packing machine

Price 410000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Mild steel

Color : Silver

Control System : PLC Control

Warranty : 1 Year

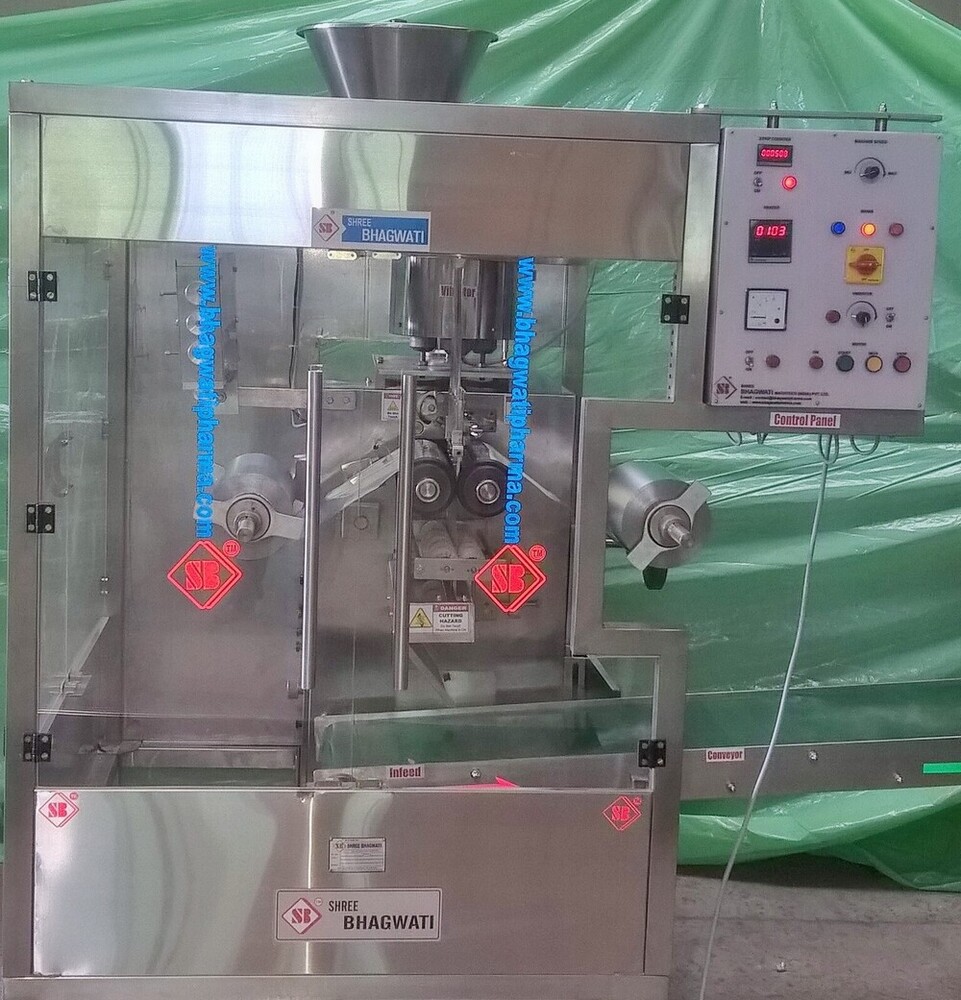

Strip Packing Machine

Minimum Order Quantity : 1 Unit

Material : Stainless steel

Color : Other

Control System : PLC Control

Warranty : 1 Year warranty

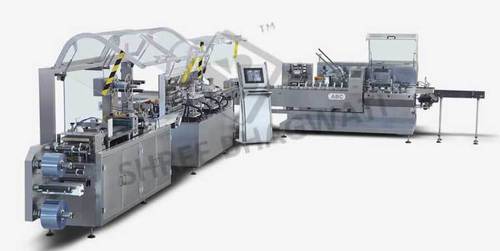

Blister Packing Machines

Price 900000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : SS

Color : Silver

Control System : Human Machine Interface

Warranty : 1 Year

PVC Blister Packing Machine

Price 450000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Material : stainless steel

Color : Silver

Control System : PLC Control

Warranty : yes

Let's talk business

Please take a moment to complete this form and a business representative will get back to you swiftly

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free