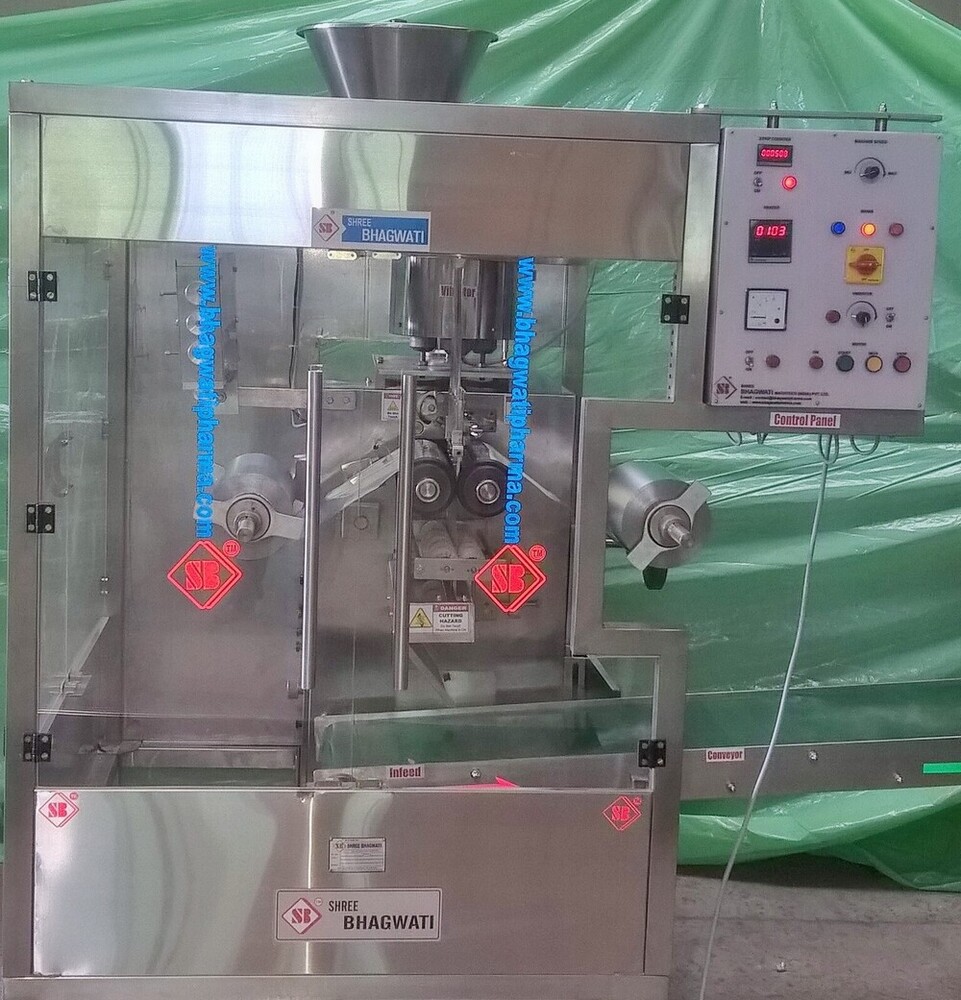

PVC Blister Packing Machine

Price 450000.00 INR/ Unit

PVC Blister Packing Machine Specification

- Material

- stainless steel

- Feature

- Highly Efficient

- Computerized

- Yes

- Automatic Grade

- Semi-Automatic

- Control System

- PLC Control

- Drive Type

- Electric

- Voltage

- 220 Volt (v)

- Color

- Silver

- Warranty

- yes

PVC Blister Packing Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- Unit

- Delivery Time

- 6-8 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden packing only

- Main Domestic Market

- All India

- Certifications

- CE & ISO Certified

About PVC Blister Packing Machine

Is a high speed packing suitable for a variety of products, such as tablets and capsules. High quality sealing is achieved with features such as proportional temperature controls, variable sealing roller pressure and rugged and precision construction

Technical Specifications:

| Products | Tablets, Draggers , Snap fit Capsules, Soft Gelatin Capsules etc. |

| Packaging Materials | Base Film, PVS opaque or transparent (thermo formable) and non-toxic |

|

| PVC with PVDC coating |

| | PVC with PE/PVDC |

| Lading Material | Aluminium (had) with heat-saleable lacquer or PVDC coating |

| Format Range | SB Pack 150 |

| PVC Base Film Width max. | 120 mm |

| PVC Film Thickness max. | 0.2 - 0.3 mm |

| PVC Reel Dia. max. | 440 mm |

| Aluminum Foil Width max. | 116 mm |

| Aluminum Foil Thickness max. | 0.02 - 0.03 mm |

| Aluminum Foil Roll Dia. max. | 210 mm |

| Total Forming Area | 120 x 25 mm |

|

| 120 x 100 mm |

| Pack Length | 110 mm |

| Pack Width | 100 mm |

| Forming Depth | 10 mm |

| Output | 150 Packs |

|

| 1500 tabs/min |

| Floor Space | 1800 (L) x 500 (D) |

| | 1500 (H) mm |

| Electrical | 1 HP. 1 AMP (16 heater 8 forming and 8 sealing roller) = 16 amp.ase. |

| Power requirement | 5 KW approx. |

| Recommended Spares and change over parts. Blister Forming Roller, Sealing Roller, Guide Track, Channel, Cutting Dye, Cutting Gear And Batch Printing Gear. | |

Advanced Packaging Efficiency

This PVC Blister Packing Machine ensures high-speed and accurate packaging, suitable for various industries. Its semi-automatic operation, combined with PLC control, minimizes manual intervention and maximizes throughput, offering consistent output and reliability in every batch.

Durable Stainless Steel Construction

Manufactured using stainless steel, the machine guarantees longevity and resistance to corrosion, making it ideal for continuous use in industrial settings. Its sleek silver finish also ensures easy cleaning and maintenance, upholding hygiene standards required in packaging environments.

Flexible Capacity and Customization

With a flexible capacity ranging from 2 to 12 tracks and adjustable voltage options, this machine adapts to different packaging requirements and customer specifications. Its robust design supports a wide range of packaging formats for increased production versatility.

FAQs of PVC Blister Packing Machine:

Q: How does the PVC Blister Packing Machine operate?

A: The machine operates with either a mechanical or electric drive and utilizes a PLC control system for automated packaging. Simply load the packaging material and set your parameters; the machine will efficiently form, fill, and seal the blister packs in sequence.Q: What materials can be packaged using this machine?

A: It is engineered for packaging using PVC and similar blister-compatible materials, making it ideal for pharmaceuticals, consumer goods, and related products requiring air-tight, tamper-proof sealing.Q: When is maintenance required for this machine?

A: Regular maintenance should be scheduled based on usage intensity. Typically, routine inspection and cleaning of components are recommended after each production cycle, and a more thorough servicing should be performed monthly to ensure consistent performance.Q: Where is the PVC Blister Packing Machine best utilized?

A: This machine is ideally suited for use in pharmaceutical plants, consumer goods manufacturing units, and other packaging environments that demand precision and efficiency in product containment.Q: What is the benefit of the PLC control system?

A: The integrated PLC control system allows for customizable operations, precise process monitoring, and minimized manual intervention. This results in uniform packaging quality and improved operational safety for users.Q: Can the machines voltage be customized as per requirements?

A: Yes, the machine provides adaptable voltage options, including standard 220V and other configurations, as per customer requirements, to ensure compatibility with local power standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Capsule and Tablets Blister Packing Machine Category

Strip Packing Machine

Minimum Order Quantity : 1 Unit

Warranty : 1 Year warranty

Color : Other

Voltage : Single & Three Phase Watt (w)

Control System : PLC Control

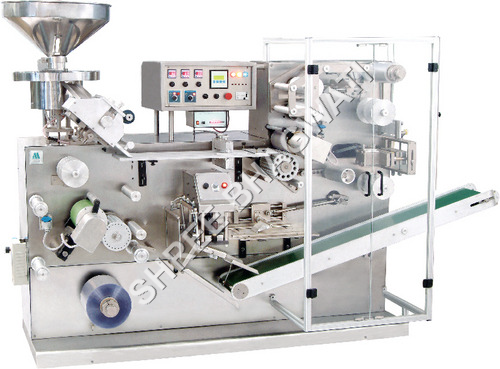

Blister Packing Machine

Price 410000 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : 1 Year

Color : White

Voltage : 415 Volt (v)

Control System : PLC Control

Blister Packing machine

Price 410000 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : 1 Year

Color : Silver

Voltage : 415 Volt (v)

Control System : PLC Control

Blister Packing Machines

Price 900000 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : 1 Year

Color : Silver

Voltage : 110215 Volt (v)

Control System : Human Machine Interface

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS