Sticker Labelling Machine

Price 450000 INR/ Unit

Sticker Labelling Machine Specification

- Product Type

- Sticker Labelling Machine

- Material

- SS

- Computerized

- No

- Automatic Grade

- Automatic

- Control System

- Human Machine Interface

- Drive Type

- Electric

- Feature

- ECO Friendly

- Warranty

- 1 Year

Sticker Labelling Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Cash Against Delivery (CAD), Cash Advance (CA), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque

- Supply Ability

- 30 Units Per Month

- Delivery Time

- 6 Week

- Sample Available

- Yes

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Packaging Details

- Wooden Packing Only

- Main Domestic Market

- All India

- Certifications

- CE & ISO Certified

About Sticker Labelling Machine

Self Adhesive Vial / Bottle Sticker Labelling Machine

| The Automatic Vertical Sticker Labelling Machine is one of the most users friendly. The machine is used for full/partial wrap around vial / bottle labelling on different size of round container sticker labelling machine. It is capable up to 100-120 vials/containers per minutes depending on products and label size. The automatic model is equipped with roller spacing device resulting in a simple to "No change parts required". | ||||||||||||||||||||||

| Operation : | ||||||||||||||||||||||

| The vials sticker labelling machine, bottles sticker labelling machine and contraire sticker labelling machine are positioned & accurate spacing between two containers by the roller spacing device for wrap-around operation at the operation at the labelling point, an electronic product sensor container & release a label from self adhesive label roll. The sensed vials moves on conveyor sticker label at labelling point wrapped around to container. Then the labelled container moves further through a rubber pressing belt & stationary rubber pad that ensures neat & perfect fixing of label. | ||||||||||||||||||||||

| Salient Features : | ||||||||||||||||||||||

| ||||||||||||||||||||||

| Utility Requirement : | ||||||||||||||||||||||

| ||||||||||||||||||||||

| Technical Details: | ||||||||||||||||||||||

| ||||||||||||||||||||||

| * Depending on the shape and size of container and label size. Can be supplied as per customer requirements. | ||||||||||||||||||||||

| Input Specifications: | ||||||||||||||||||||||

| ||||||||||||||||||||||

* Depends on size, shape and Neck Dia of container, Fill volume and nature of liquid etc.

Can be supplied as per customer requirements.

With help of change parts.

* Note : With the help of the change parts.

Robust Stainless Steel Construction

Built from high-quality stainless steel, our machine offers seamless durability for rigorous labeling tasks. Its robust structure not only guarantees longevity, but also ensures minimal maintenance, making it a solid choice for continuous operation in demanding industrial settings.

Advanced Control and Flexibility

Operate with ease using the choice of a Human Machine Interface or PLC control system. The automated setup streamlines processes for efficient and consistent labeling, while compatibility with various voltage requirements ensures adaptability to diverse manufacturing environments.

Eco-Friendly and User-Oriented

Engineered with sustainability in mind, this machine is eco-friendly and minimizes power wastage. Despite its advanced features, it remains straightforward to operate, catering to both manual and computerized workflows, and enhancing overall workplace productivity.

FAQs of Sticker Labelling Machine:

Q: How does the Sticker Labelling Machine operate and what is its drive type?

A: The Sticker Labelling Machine operates automatically with an electric drive, ensuring smooth, consistent labeling on products without manual intervention. Users can control the operation via Human Machine Interface or a PLC control system.Q: What materials and power specifications are supported by the machine?

A: Manufactured using premium stainless steel (SS), the machine is robust and corrosion-resistant. It supports voltage and power requirements tailored to the customers needs, making it highly versatile for various industrial setups.Q: When can I expect delivery and installation support for the machine in India?

A: As a distributor, exporter, manufacturer, and supplier based in India, we ensure prompt delivery across the country. Installation support and operational guidance are provided following purchase to ensure a seamless startup process.Q: Where can the Sticker Labelling Machine be used most effectively?

A: This machine is ideal for application on production lines in pharmaceutical, food and beverage, cosmetic, and other industries where precise, rapid sticker labeling is essential for packaging and branding.Q: What is the process for customizing the labelling machines voltage and settings?

A: Upon request, we configure the machines voltage and operational settings to match your sites requirements. Our technical team confirms specifications with you before manufacturing and provides guidance during installation and setup.Q: How do I benefit from the machines automatic and eco-friendly features?

A: The automatic function greatly increases productivity by reducing manual labor, while eco-friendly design principles ensure reduced energy consumption and minimized operating costs. This results in a more sustainable and cost-effective labeling solution.Q: Is the machine computerized and how does this affect its usage?

A: The Sticker Labelling Machine is available in both computerized and non-computerized versions. Computerized options offer enhanced control and monitoring for precise label application, benefiting users seeking advanced automation and process oversight.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bottle and Vials Liquid Filling Machine Category

Volumetric Liquid Bottle Filling

Price 450000 INR / Unit

Minimum Order Quantity : 1 Unit

Control System : Human Machine Interface

Product Type : Other

Warranty : 1 Year

Heating System : Other

Automatic Filling Machine

Price 490000 INR / Unit

Minimum Order Quantity : 1 Unit

Control System : Human Machine Interface

Product Type : Filling Machine

Warranty : 1 Year

Heating System : Other

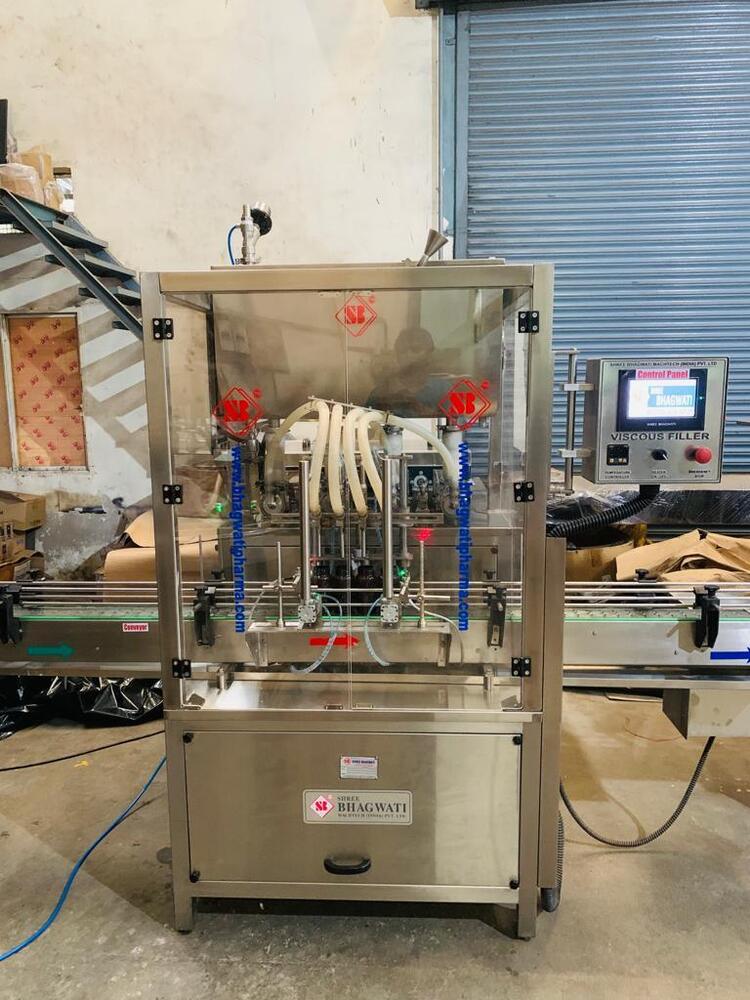

Viscous Liquid Filling machine

Price 1200000 INR / Unit

Minimum Order Quantity : 1 Piece

Control System : Human Machine Interface

Product Type : Other

Warranty : 1 Year

Heating System : Other

Injectable Dry Powder Filling

Price 1200000 INR / Unit

Minimum Order Quantity : 1 Piece

Control System : PLC Control

Product Type : Other

Warranty : 1 Year warranty

Heating System : Other

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free