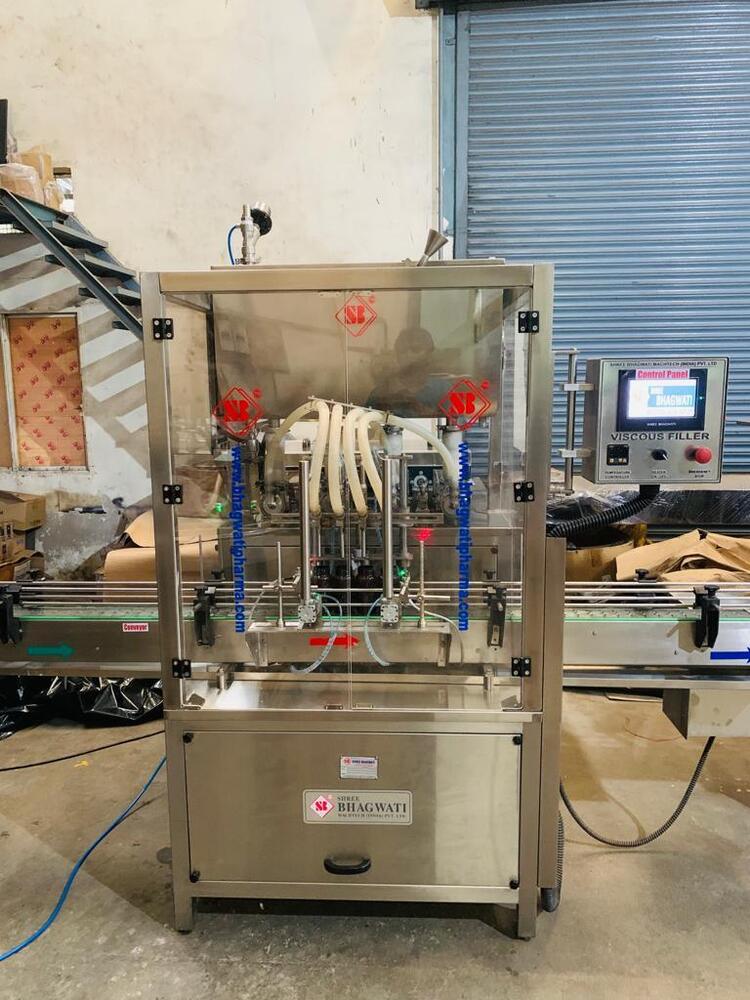

Automatic Filling Machine

Price 490000 INR/ Unit

Automatic Filling Machine Specification

- Product Type

- Filling Machine

- Material

- SS

- Computerized

- No

- Automatic Grade

- Automatic

- Control System

- Human Machine Interface

- Drive Type

- Electric

- Feature

- ECO Friendly

- Warranty

- 1 Year

Automatic Filling Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 30 Units Per Month

- Delivery Time

- 4-6 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Packing Only

- Main Export Market(s)

- Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Asia

- Main Domestic Market

- All India

- Certifications

- CE & ISO Certified

About Automatic Filling Machine

Operation:

Automatic Volumetric Liquid bottle filling machine Nozzle goes upwards slowly from the bottom level of bottle towards neck during filling to minimize forming adjustable nozzle is reciprocating according to filling dose

The dosing block with a hexagonal bolt, this means different fill size can be set easily within minimum of time.

The main drive consists of a helical gearbox driven by A/c motor & through controlled by an Ac frequency drive. The speed can be set in terms of bottles per minute. The conveyor drive consists of a hallow shaft, geared motor controlled by an Ac frequency drive. A knob can set the speed of conveyor.

Technical Specification:

Model No. SBLF-100

Out/Put Up to 20-25 Bottle per minute depend on fill volume

Filling Range 100ml to 1000ml with the help of change parts

Direction of MovementLeft to Right

Number of head/syringe4 Nos.

Electrical SpecificationMain Machine2.0 HP / 415 Volts / 50 Hz.

Conveyor1

Height of Conveyor 860 mm to 910 mm adjustable.

Change parts required(A) Syringes. (B) Nozzle (C) Inlet & outlet hose pipe

Salient Features:

The unit is made compact & versatile

S.S. Elegantly Matt Finished Body

No Container No filling system.

Reciprocating Filling nozzle with self centering device

Optimized Filling Performance

Our automatic filling machine delivers a wide capacity range, ensuring accurate liquid dosing for industries such as pharmaceuticals, food processing, or chemicals. With stainless steel construction, the unit offers robust performance and resistance to corrosion. The electric drive and advanced control systems guarantee consistent, efficient operation while maintaining ease of use for operators.

User-Friendly Operation with Smart Controls

The Human Machine Interface (HMI) provides intuitive control of machine parameters. Select models also utilize PLC systems for advanced automation. These controls streamline setup and usage, reducing human error and maintaining high throughput with minimal operator input. The machines automatic grade further optimizes workflow efficiency, emphasizing hands-free operation wherever possible.

FAQs of Automatic Filling Machine:

Q: How does the automatic filling machine operate for different liquid volumes?

A: The machine uses an electric-powered system combined with precise HMI or PLC controls to accommodate filling volumes ranging from 10 ml to 1000 ml, allowing rapid adjustment for various product needs.Q: What materials are used in the construction of the filling machine?

A: This machine is constructed from high-grade stainless steel, providing maximum durability, corrosion resistance, and hygienic operation for industrial environments.Q: When should I consider using this automatic filling machine?

A: You should consider this machine when you require efficient, high-volume, and consistent filling of liquids in industries such as pharmaceuticals, chemicals, or food processing, particularly when automation and reliability are key.Q: Where is this automatic filling machine available for purchase?

A: The filling machine is offered by distributors, exporters, manufacturers, and suppliers across India, making it widely accessible for customers throughout the country.Q: What is the process for using the Human Machine Interface control system?

A: Operators can easily adjust parameters like fill volume and speed through the intuitive touchscreen HMI, simplifying machine setup and monitoring throughout production.Q: What are the main benefits of choosing this filling machine?

A: Key benefits include eco-friendly automatic operation, high capacity range, adaptability to customer voltage requirements, robust stainless steel design, and a one-year warranty for peace of mind.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bottle and Vials Liquid Filling Machine Category

Twin Track Twelve Head Liquid Filling Machine

Price 1600000 INR / Unit

Minimum Order Quantity : 1 Piece

Material : SS

Voltage : As per customer requirement Watt (w)

Warranty : 1 Year

Product Type : Other

Liquid Vial Filling With Rubber Stoppering Machine

Price 3500000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : SS

Voltage : As per customer requirement Watt (w)

Warranty : 1 Year

Product Type : Vial Filling Machine

Viscous Liquid Filling machine

Price 1200000 INR / Unit

Minimum Order Quantity : 1 Piece

Material : SS

Voltage : As per customer requirement Watt (w)

Warranty : 1 Year

Product Type : Other

Volumetric Liquid Bottle Filling

Price 450000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless steel

Voltage : As per customer requirement Watt (w)

Warranty : 1 Year

Product Type : Other

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free