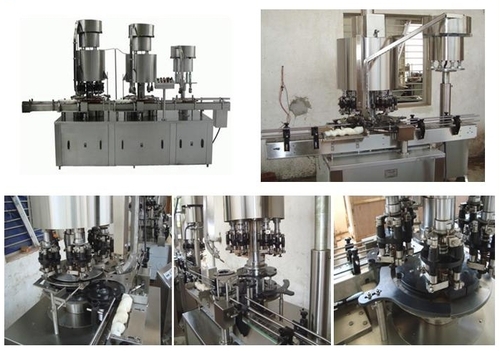

Semi Automatic Crown Capping Machine

Price 180000.00 INR/ Unit

Semi Automatic Crown Capping Machine Specification

- Type

- Capping Machines

- Material

- Stainless steel

- Auxiliary Packaging Machine Type

- Other

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Control System

- Human Machine Interface

- Drive Type

- Mechanical

- Voltage

- As per the client required Watt (w)

- Warranty

- 1 year

Semi Automatic Crown Capping Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- India

- Payment Terms

- Cash Against Delivery (CAD), Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Days after Acceptance (DA), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 30 Units Per Week

- Delivery Time

- 4-6 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden packing only

- Main Domestic Market

- All India

- Certifications

- ISO and CE Certified

About Semi Automatic Crown Capping Machine

Operation

Require manually feeding & unloading container, where the body and the neck of the container are positioned below the rotating head and sealing head is performing perfect operation of capping with uniform torque.

Technical Specification

| Model | SBSC-40C |

| Output | 8-10 BPM - Depending on operator speed |

| No. of sealing head | 1 Nos. |

| Electrical Motor | 1 HP / 440 Volts / 3 Phase / 50 Hz (Four wire) For Main Machine |

| Change parts required | Cap Die if cap diameter change. |

Precision Control with Human Machine Interface

Enjoy intuitive operation with the integrated Human Machine Interface, which guides users through each step of the capping process. This feature enhances user control and ensures accuracy, even without computerized elements, making it easy to learn and operate in busy production environments.

Adaptable Voltage for Diverse Needs

The capping machines voltage can be customized according to client requirements. This flexibility guarantees compatibility in various locations and facilities, reducing installation concerns and providing hassle-free integration into existing bottling lines.

Durability and Reliability for Industry

Fabricated from robust stainless steel, the machine is built to withstand rigorous use and maintain hygiene standards. Backed by a one-year warranty and offered by trusted Indian distributors and exporters, it represents a reliable investment for manufacturers and suppliers.

FAQs of Semi Automatic Crown Capping Machine:

Q: How does the Semi Automatic Crown Capping Machine operate?

A: This capping machine works by using a mechanical drive system and is controlled through a Human Machine Interface, requiring operator intervention for loading and unloading bottles while the capping process itself is automated.Q: What materials are suitable for use with this capping machine?

A: The machine is constructed from stainless steel, which ensures hygiene and longevity, making it suitable for capping glass or plastic bottles in beverage and food applications.Q: When is maintenance required for the machine, and what is covered under warranty?

A: Routine maintenance is recommended based on usage frequency and production volume. The included one-year warranty covers manufacturer defects and major mechanical failures but does not extend to routine wear-and-tear or misuse.Q: Where can I install this capping machine and how is the voltage configured?

A: The machine can be installed in any bottling facility, and its voltage is configurable according to the clients requirements, allowing seamless integration into diverse production setups across India and internationally.Q: What is the benefit of using a semi-automatic rather than a fully automated capping machine?

A: A semi-automatic capping machine offers greater operational flexibility and is ideal for medium-scale production where manual oversight is needed to ensure quality and adaptability to different bottle sizes or production batches.Q: How does the Human Machine Interface improve the capping process?

A: The Human Machine Interface simplifies the process by providing guided instructions and operational feedback, minimizing errors and making it accessible for operators without specialized computerized training.Q: What types of businesses can benefit from this machine?

A: Distributors, exporters, manufacturers, and suppliers in beverage, chemical, and food sectors will find this capping machine advantageous due to its flexibility, reliability, and easy maintenance in moderate production environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Capping Machine Category

Two Head Rotary Servo Capping Machine

Minimum Order Quantity : 1 Piece

Material : Stainless steel

Automatic Grade : Automatic

Computerized : Yes

Drive Type : Electric

Automatic Single Head Linear Bung & Capping Machine

Minimum Order Quantity : 1 Piece

Material : Stainless steel

Automatic Grade : Automatic

Computerized : Yes

Drive Type : Electric

Automatic 6 Head Screw Capping Machine

Price 800000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless steel

Automatic Grade : Automatic

Computerized : Yes

Drive Type : Electric

Muti Head ROPP Capping machine

Price 1500000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : SS

Automatic Grade : Automatic

Computerized : No

Drive Type : Electric

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS