Horizontal Ampoules SBHL 110

Horizontal Ampoules SBHL 110 Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 30 Pieces Per Month

- Delivery Time

- 4-6 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Packing Only

- Main Domestic Market

- All India

- Certifications

- CE & ISO Certified

About Horizontal Ampoules SBHL 110

- Horizontal Ampoules SBHL 110

- Silent Features :

- No Object - No Label & No Label.

- No Overprinting system.

- Sturdy Frame, Large Body and Precise workmanship gives vibrations free performance.

- Variable Speed Pulley allows greater flexibility over output or optionally AC Freq. Drive System for Speed Variation.

- Suitable for Flag type and Overlap Labelling.

- Long Pressing Device for proper fixing of labels

Technical Specification

|

Model |

SBHL 110 |

|

Label Size Width X Length |

Min. 16 mm (W) 20 mm (L) Max. 90 mm (W) 110 mm (L) |

|

Ampoules / Vials Diameter |

Min. Dia. 10 mm Max. Dia. 50 mm |

|

Max. Output Labels / Min. |

Upto 100 Labels / Min. |

Advanced Automation for Seamless Production

The SBHL 110 stands out for its fully automatic operation, reducing manual intervention and increasing productivity. Its computerized PLC control system ensures precise ampoule handling, filling, and sealing, enhancing output consistency and reducing errors during the manufacturing process.

Durable Stainless Steel Construction

Constructed from premium stainless steel, this machine is built to withstand intensive industrial use. Its corrosion-resistant body ensures longevity and easy maintenance, making it a robust investment for any pharmaceutical or chemical production facility.

Customizable Electrical Specifications

Understanding that voltage requirements vary, the SBHL 110 offers tailored electrical configurations to adapt to diverse locations. This flexibility enables seamless integration across various regions and facilities, ensuring consistent performance wherever it is installed.

FAQs of Horizontal Ampoules SBHL 110:

Q: How does the Horizontal Ampoules SBHL 110 operate automatically?

A: The SBHL 110 runs on a PLC-controlled system, automating the entire ampoule filling and sealing process. Operators simply program the required parameters, and the machine handles ampoule feeding, precise filling, and sealing without manual oversight.Q: What materials are used for manufacturing the SBHL 110, and why?

A: The machine is manufactured using high-grade stainless steel, chosen for its robustness, corrosion resistance, and compliance with pharmaceutical industry standards. This ensures product purity and long-lasting performance.Q: When and where can the SBHL 110 be installed?

A: The SBHL 110 is suitable for any facility requiring high-volume ampoule processing, such as pharmaceutical plants or chemical factories. It can be installed as soon as the site is prepared with suitable electrical power, which can be customized to match local requirements.Q: Where is the SBHL 110 manufactured and shipped from?

A: This model is produced by an established manufacturer in India. It is available for domestic use as well as for export to various international markets through authorized distributors and suppliers.Q: What is the process for operating and maintaining the SBHL 110?

A: To operate the SBHL 110, users input operational settings via the computerized interface, after which the machine conducts automated filling and sealing. For maintenance, routine cleaning and regular system checks are recommended, which are made easier thanks to the stainless steel design.Q: How does using the SBHL 110 benefit production?

A: Utilizing this automatic ampoule filling and sealing machine increases efficiency, ensures consistent product quality, and reduces the risk of contamination. Automated control minimizes human error and optimizes throughput, ultimately saving time and operational costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sticker Labelling Machine Category

Top Labeling machine for Cartons,Box,Battary

Price 600000 INR / Unit

Minimum Order Quantity : 1 Piece

Product Type : Other

Drive Type : Electric

Capacity : 30300 T/hr

Control System : Human Machine Interface

Automatic Vial labeling Machine

Price 450000 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Other

Drive Type : Electric

Capacity : 60120 BPM Kg/hr

Control System : Human Machine Interface

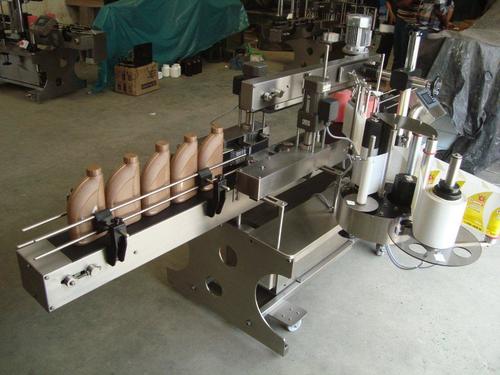

automatic front and back labeling machine

Price 750000 INR / Unit

Minimum Order Quantity : 1 Piece

Product Type : Other

Drive Type : Electric

Capacity : 60120 BPM Ton/day

Control System : Human Machine Interface

Tube Labeller Machine

Price 750000 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Other

Drive Type : Electric

Capacity : 30300 Ton/day

Control System : Human Machine Interface

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free