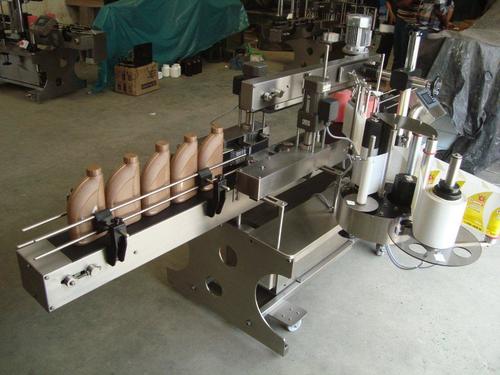

automatic front and back labeling machine

Price 750000 INR/ Unit

automatic front and back labeling machine Specification

- Material

- SS

- Computerized

- No

- Automatic Grade

- Automatic

- Control System

- Human Machine Interface

- Drive Type

- Electric

- Feature

- ECO Friendly

- Warranty

- 1 year

automatic front and back labeling machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 30 Pieces Per Month

- Delivery Time

- 4-6 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- wooden Packing only or For more Details on www.labelingmachineindia.net

- Main Domestic Market

- All India

- Certifications

- CE & ISO Certified

About automatic front and back labeling machine

Specification Of The Equipment Machine Basics

- Automatic Front and Back Labeling Machine

- Model- Servo Based Machine

- Product- Round Mineral Water Bottle

- Production Speed Per Minute-Up to 80 Products per Minute (Speed Depends up on the Size of the Product and label length).

- Number of Labeling Dispenser-2 Labeling Dispenser Head

- Application- Labeling on front and back side of round container

- Labels Requirement- Self Adhesive Sticker Labels in Roll Form having consistence 3 mm gaps between the 2 labels.

- Label Material- Self Adhesive Cromo Paper Labels

- Label Roll Outer Diameter- Maximum 300 mm

- Label Core ID-75 mm

- Label Dispensing Accuracy-+1 mm

- Container Holding Unit

- Belt Type Spring Based Top Conveyor.

- Working Heigh 850 mm (+50 mm)

- Conveyor Length- 8 Feet

- Machine Weight- Approx 350 Kgs

- Machine Dimension- Approx 8 (L) x 7 (W) x 5 (H) in Feet

- Transparent Sensor- Extra Cost

Machines Material Of Construction

| Machine Main Base Frame | Mild Steel or Stainless Steel 304 |

| Machine Coverings | Complete in Stainless Steel 304 |

| Product Contact Parts | Stainless Steel 304 |

| Non Contact Parts | Stainless Steel / Mild Steel / Aluminum / Teflon (Whichever is applicable) |

| Conveyor Belt | Rubber Belt (Stainless Steel for heavy products) |

| Conveyor Shafts | Mild Steel with Hard Chrome or Zinc Plating |

| Conveyor Sprockets | Mild Steel or Nylon |

| Bearings | SKF / Niche / Equivalent |

| Plating(Wherever Applicable) | ENP / Zinc / Hard Chrome / Blackening |

| TOP Conveyor Belt | Timing Sponge Belt |

| Guide Rod & Pin | Stainless Steel 304 |

| Dispenser Rollers | Rubber Molded + Aluminum + Knurling Rollers |

| Dispenser Unit Up & Down | Screw Based UP & DOWN Assembly |

State-of-the-Art Control System

Equipped with advanced Human Machine Interface and PLC control, this labeling machine makes operation simple and reliable. The intuitive touch screen allows for swift adjustments, maximizing productivity and reducing downtime while fostering a user-friendly experience.

Outstanding Energy Efficiency

Engineered for lower energy consumption, the automatic labeling machine delivers top-notch performance with minimal environmental impact. Its electric drive ensures smooth high-speed operation while upholding ECO-friendly standards in manufacturing and daily use.

FAQs of automatic front and back labeling machine:

Q: How does the automatic front and back labeling machine operate?

A: The machine utilizes electric power to drive its labeling system, which automatically applies labels to the front and back of containers at speeds ranging from 60 to 120 BPM. Its touch screen interface allows operators to manage settings effortlessly, optimizing the labeling process.Q: What materials are used to manufacture this labeling machine?

A: Constructed from high-quality stainless steel (SS), the machine ensures corrosion resistance, structural strength, and longevity, making it suitable for use in demanding industrial environments.Q: When can I expect the machine to be fully functional after installation?

A: Once installed and connected to power, setup is minimal thanks to its simple control system. Operators can configure the desired labeling parameters quickly using the touch screen, making the machine ready for use almost immediately.Q: Where is this labeling machine manufactured and available for purchase?

A: This labeling machine is manufactured, supplied, and exported by distributors in India. Interested buyers can contact authorized suppliers or exporters directly for ordering and technical support.Q: What benefits does this machine offer for large-scale production?

A: Its high efficiency, automatic operation, and rapid labeling speed make it ideal for large-scale production. The machine reduces manual labor, lowers operational costs, and ensures consistent, high-quality labeling, boosting overall productivity.Q: How does the process of labeling with this machine enhance product presentation?

A: The automated system ensures accurate front and back labeling, enhancing the visual appeal and consistency of each package. This professional finish strengthens brand perception and supports compliance with packaging standards.Q: What warranty is provided with this labeling machine and what does it cover?

A: All machines come with a one-year warranty, which covers manufacturing defects and offers repair or replacement of faulty parts within the warranty period, ensuring reliable operation and peace of mind for users.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sticker Labelling Machine Category

High Speed Vertical Sticker Labelling Machine

Price 900000 INR / Unit

Minimum Order Quantity : 1 Piece

Material : SS

Drive Type : Electric

Product Type : Other

Computerized : No

Vertical Sticker Labeling Machine

Price 450000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless steel

Drive Type : Electric

Product Type : Other

Computerized : No

Front Back Sticker Labelling Machine

Price 750000 INR

Minimum Order Quantity : 1 Piece

Material : stainless steel

Drive Type : Electric

Product Type : Labeling Machine

Computerized : Yes

Automatic Vial labeling Machine

Price 450000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : SS

Drive Type : Electric

Product Type : Other, Vial Labeling Machine

Computerized : No

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free