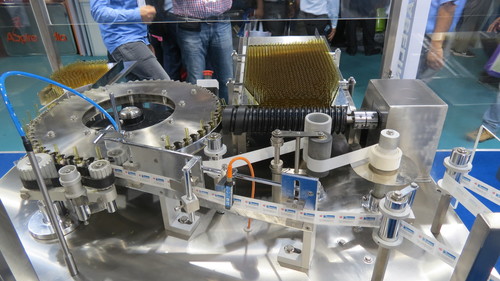

High Speed wet Glue Labeling Machine

Price 800000 INR/ Unit

High Speed wet Glue Labeling Machine Specification

- Product Type

- Wet Glue Labeling Machine

- Material

- SS

- Computerized

- No

- Automatic Grade

- Automatic

- Control System

- Human Machine Interface

- Drive Type

- Electric

- Feature

- ECO Friendly

- Warranty

- 1 year

High Speed wet Glue Labeling Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 30 Units Per Month

- Delivery Time

- 4-6 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Packing Only

- Main Domestic Market

- All India

- Certifications

- CE & ISO Certified

About High Speed wet Glue Labeling Machine

- A/C Frequency Drive for speed control.

- All exposed parts of the unit are S.S, hard chromed or SS cladded to ensure long life and resistance against corrosion.

- Adjustable Conveyor Height to align with other machine of the line.

- Minimum changeover time is required from one size of container or label to another.

- Special self-aligning bearing ensure smooth & trouble free rotation of the parts

- These self-aligning bearing help in quick assemble during periodical maintenance of the unit. They also allow more flexibility in maintaining tolerances.

- No container, No label, an electrical sensing device avoids wastage of labels; it also helps in keeping the unit neat & clean.

- Suitable for overlap labeling and flag type labeling where the length of label is more than the circumference of container.

- A highly efficient vacuum pump develops sufficient vacuum to hold labels big or small on the pick-up cylinder..

- Complete protection of the motors is ensured by the contractors and relays of appropriate ratings.

- Code over Printing Device.

- Safety Guard.

Optional Accessories :

- Digital counter for output of container

- Attachment for flat bottle.

- Special design for one label up to 165 mm length & 120 mm width.

- Water tuff to keep wet gum roller & muster.

| Technical Specification: | ||

| Model | SHL - 150 | |

| Direction of Movement | Left to Right | |

| Output / Hour* | 3600 to 9000 nos | |

| Electrical Specification | Main Motot | 0.75 HP / 415 Volts / 50 Hz. |

| Vacuum Pump | 0.5 HP / 415 Volts / 50 Hz. | |

| Height of Conveyor | 860 mm to 910mm | |

| Machine Dimensions (In mm) L x W x H | 3010 x 1016 x 1170 | |

| Case Dimensions | 3250 x 1250 x 1200 | |

| Net Weight | 550 Kgs. | |

| Gross Weight | 750 Kgs. | |

| Change Parts Required | (A) Container : Feed Worm | |

| (B) Label: Label musters, Upper - Lower Plate, Pusher Plate | ||

| Input Specification: | ||

| Label Specification | Length | 20 mm to 140 mm |

| Width | 15 mm to 90 mm | |

| Thickness | 65 to 75 GSM (The Direction of Grains of the label must always be parallel to the containers axis. The paper should be flexible) | |

| Container size | Round Shape | 16 mm to 100 mm |

| Respectively height 40 mm to 240 mm | ||

| (Height option for other bottle height available.) | ||

| Wet Glue | Glass/Plastic/PET etc. | As Per recommended in user manual. |

Precise and Efficient Labeling

Achieve consistent and high-speed labeling on your products with this automatic wet glue labeling machine. The efficient use of glue ensures reduced wastage and a neat finish on every application. Its stainless steel construction guarantees both durability and easy maintenance, making it ideal for demanding production environments.

Flexible and Customizable Operations

Thanks to its adaptable control system, including Human Machine Interface and optional PLC control, this machine can be easily tailored to meet your specific operational needs. The voltage can be configured as per customer requirements, ensuring seamless integration into existing production lines for distributors and manufacturers.

Sustainable and User-Friendly

This wet glue labeling machine operates with eco-friendly features and is fully automated, minimizing human error and energy consumption. The electric drive further adds to its efficient energy profile, while the clear interface streamlines day-to-day use and decreases downtime during changeovers or maintenance.

FAQs of High Speed wet Glue Labeling Machine:

Q: How does the High Speed Wet Glue Labeling Machine operate?

A: The machine operates automatically, feeding containers and labels before efficiently applying wet glue labels at high speed. Operators can control settings and monitor performance through the Human Machine Interface or PLC control, depending on the configuration.Q: What materials are used in the construction of this labeling machine?

A: This machine is crafted from high-quality stainless steel, which provides resistance to corrosion, easy cleaning, and a hygienic surface for industrial applications.Q: When is maintenance typically required for this labeling machine?

A: Regular maintenance is recommended based on usage intensity, but the robust stainless steel design and electric drive generally require minimal upkeep. The supplied documentation outlines maintenance schedules to maximize operational efficiency.Q: Where can the High Speed Wet Glue Labeling Machine be installed?

A: The machine is suitable for industrial, manufacturing, and packaging environments across India. Its voltage adaptability allows it to be configured for various local power supplies as per customer specifications.Q: What is the process of setting up this labeling machine?

A: After installation at your facility, setup involves configuring the voltage, loading labels and glue, and calibrating operational parameters through the control system. Assistance is available from the manufacturer or authorized suppliers if required.Q: How is this machine beneficial for distributors and manufacturers?

A: With its high speed, automatic operation, and eco-friendly features, the machine streamlines labeling tasks, boosts productivity, and reduces operational costs. The 1-year warranty assures reliable support for seamless business operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Labeling Machine Category

Automatic Rotary Sticker Labeling Machine

Price 750000 INR / Unit

Minimum Order Quantity : 1 Unit

Drive Type : Electric

Material : SS

Computerized : No

Automatic Grade : Automatic

Automatic Pallet Labelling Machine

Price 1200000 INR / Unit

Minimum Order Quantity : 1 Unit

Drive Type : Electric

Material : SS

Computerized : No

Automatic Grade : Automatic

Automatic Ampoule Labelling Machine

Price 800000 INR / Unit

Minimum Order Quantity : 1 Piece

Drive Type : Electric

Material : SS

Computerized : No

Automatic Grade : Automatic

Automatic Flat Bottle Labeling Machine

Price 600000 INR / Unit

Minimum Order Quantity : 1 Unit

Drive Type : Electric

Material : SS

Computerized : No

Automatic Grade : Automatic

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free