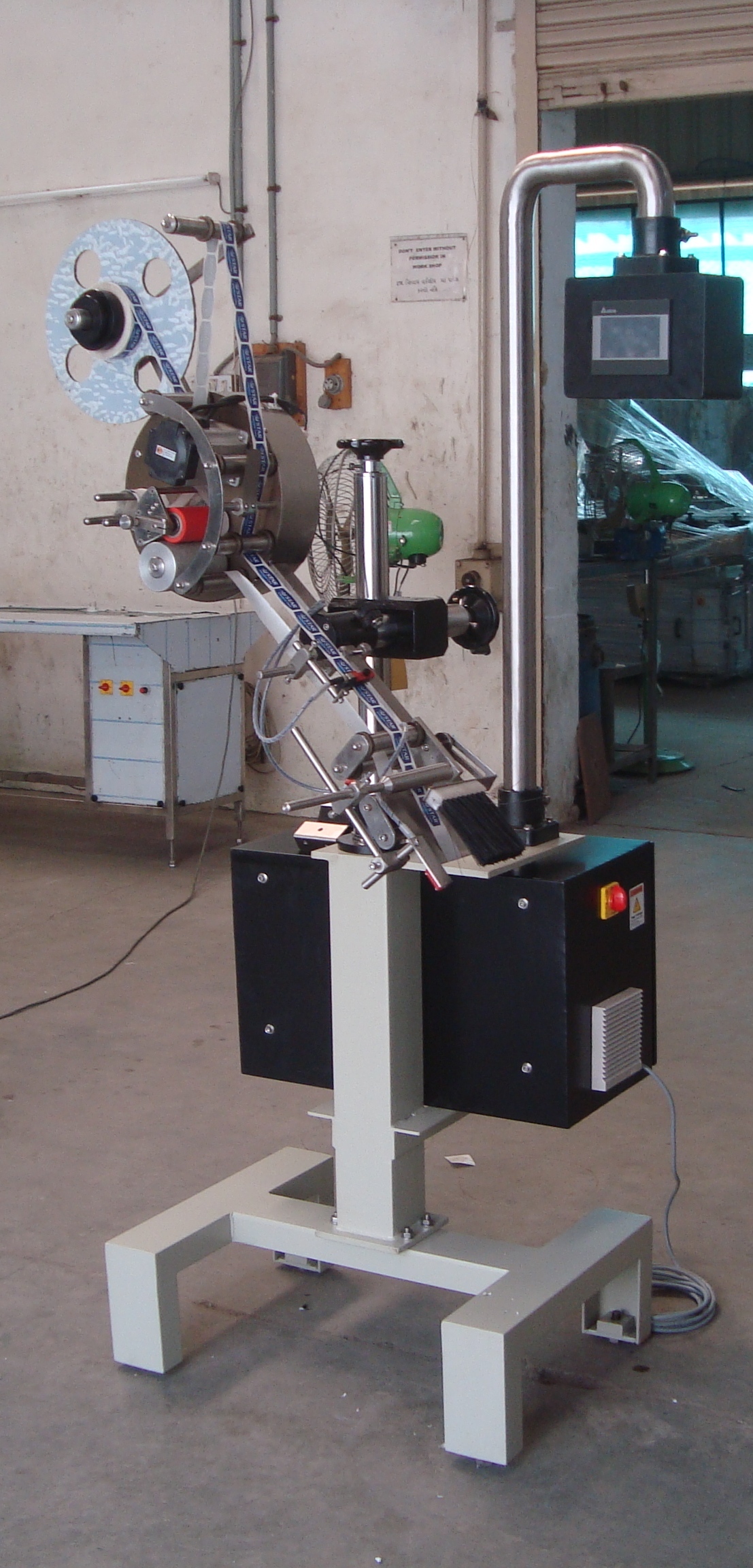

Automatic Pallet Labelling Machine

Price 1200000 INR/ Unit

Automatic Pallet Labelling Machine Specification

- Product Type

- Pallet Labelling Machine

- Material

- SS

- Computerized

- No

- Automatic Grade

- Automatic

- Control System

- Human Machine Interface

- Drive Type

- Electric

- Power Source

- Electric

- Voltage

- 220-415 Volt (v)

- Warranty

- 1 year

Automatic Pallet Labelling Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 30 Units Per Month

- Delivery Time

- 4-6 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- wooden packing only

- Main Domestic Market

- All India

- Certifications

- CE & ISO Certified

About Automatic Pallet Labelling Machine

The automatic horizontal labelapplicator machine is one of the most users friendly. The Machine incorporatedwith latest SERVO or sophisticated Micro Processor Control Label dispensingsystem with user friendly Sensing system for Label and Product. It is suitablefor sticker labeling on Products and other flat surface container. It is capabilityof labeling is up to 300 Products per minute depending on products diameter andlabel size. Our model - 60 / 120 /150 /250/ 300/ 400 /600 products per minutedepends on application and systems.

SPECIFICATION OF THE EQUIPMENTMACHINES BASICS

| Machine Name | Stand Alone Label Applicator |

| Model | Stepper Based Machine |

| Suitable for Products | Floor & Pallet |

| Distance between two products | On customers scope |

| Application | Labeling on Straight Surface of product. |

| Labels Requirement | Self Adhesive Sticker Labels in Roll Form having consistence 3 mm gaps between the 2 labels. |

| Label Material | Self Adhesive Paper Labels |

| Label Roll Outer Diameter | Maximum 300 mm |

| Label Core ID | 75 mm |

| Label Dispensing Accuracy | +1 mm |

| Working Height | 860 mm (+/-50 mm) |

| Conveyor | On customers scope |

| Machine Weight | Approx 150 Kgs |

MACHINES MATERIAL OF CONSTRUCTION

| Machine Main Base Frame | Mild Steel Pipe Structure |

| Non Contact Parts | Stainless Steel / Mild Steel / Aluminum / Teflon (Whichever is applicable) |

| Bearings | SKF / Niche / Equivalent |

| Dispenser Rollers | Rubber Molded + Aluminum + Knurling Rollers |

| Dispenser Unit Up & Down | Screw Based UP & DOWN Assembly |

OPTIONAL FEATURE

- Label Roll Empty Machine Stop System with Alarm.

- Missing Label in Roll Machine Stop System with Alarm.

- Special Label Sensor for sensing Transparent Film Labels which does not have any sensing mark on it

- Option of Contact Coder, Hot Foil Coder, HP Cartridge Coder and Inkjet Coder with various speed ranges available.

- Tower Light showing the machine status / operation.

- Colour or Mono Touch Screen with PLC for machine operation and showing various error messages and information on display.

- Special Sensing system for checking missing label on product.

- Vision System for checking Barcode,presence or absence of Coding or pharma code on labels.

- Vision System with OCR system for checking coding on labels.

- Online pneumatically operated product rejection system.

Seamless Labelling Automation

Automate your pallet labelling with a machine crafted from stainless steel and engineered for durability. This solution runs entirely on electricity and delivers rapid results at speeds of 60-120 BPM, minimizing bottlenecks and boosting productivity. Its advanced HMI and PLC controls make it suitable for dynamic manufacturing environments.

Operator-Friendly Control System

Equipped with Human Machine Interface and PLC control, this machine streamlines operation for users of various skill levels. With intuitive controls and robust automation, minimal manual intervention is needed, making the system an excellent choice for companies seeking accuracy and efficiency in labelling tasks.

Reliability and Support Across India

As a leading manufacturer, exporter, distributor, and supplier in India, the machine comes with a comprehensive 1-year warranty and dependable after-sales support. This ensures peace of mind and continuous performance for your industrial or warehouse operations.

FAQs of Automatic Pallet Labelling Machine:

Q: How does the Automatic Pallet Labelling Machine operate?

A: The machine uses an electric drive system and can be managed via a Human Machine Interface or a PLC control panel, making the labelling process fully automatic and efficient.Q: What materials is the machine made from?

A: The core structure is constructed from high-grade stainless steel (SS), providing exceptional durability and resistance to corrosion in industrial settings.Q: When is the ideal time to use this machine in a production process?

A: It is best utilized at the final stage of packaging or inventory management when pallets require clear, accurate labelling before distribution or storage.Q: Where can the Automatic Pallet Labelling Machine be installed?

A: The system is designed for flexibility in installation and can be set up in various industrial environments across India, including warehouses, manufacturing units, and logistics hubs.Q: What processes does the machine automate?

A: It automates the attachment of labels onto pallets, ensuring each unit is accurately identified and traced through supply chain processes without manual intervention.Q: How does using this machine benefit my business?

A: Automating pallet labelling enhances operational efficiency, reduces human error, and increases throughput, supporting better inventory management and faster order fulfillment.Q: What kind of warranty and service support is available?

A: A one-year warranty is provided, covering manufacturing defects. As a distributor, exporter, and supplier, comprehensive after-sales support is also available throughout India.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Labeling Machine Category

Stand Alone Label Applicator

Price 375000 INR / Unit

Minimum Order Quantity : 1 Unit

Drive Type : Electric

Computerized : No

Material : SS

Automatic Grade : Automatic

Automatic Rotary Sticker Labeling Machine

Price 750000 INR / Unit

Minimum Order Quantity : 1 Unit

Drive Type : Electric

Computerized : No

Material : SS

Automatic Grade : Automatic

Automatic Flat Bottle Labeling Machine

Price 600000 INR / Unit

Minimum Order Quantity : 1 Unit

Drive Type : Electric

Computerized : No

Material : SS

Automatic Grade : Automatic

Rotary Sticker labelling Machine

Price 900000 INR / Unit

Minimum Order Quantity : 1 Unit

Drive Type : Electric

Computerized : No

Material : SS

Automatic Grade : Automatic

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free