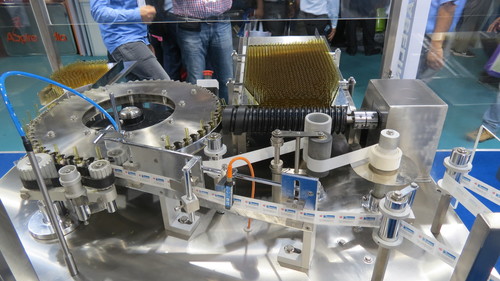

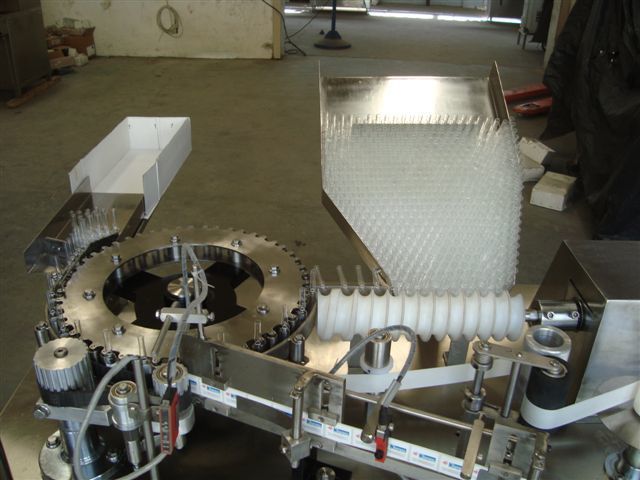

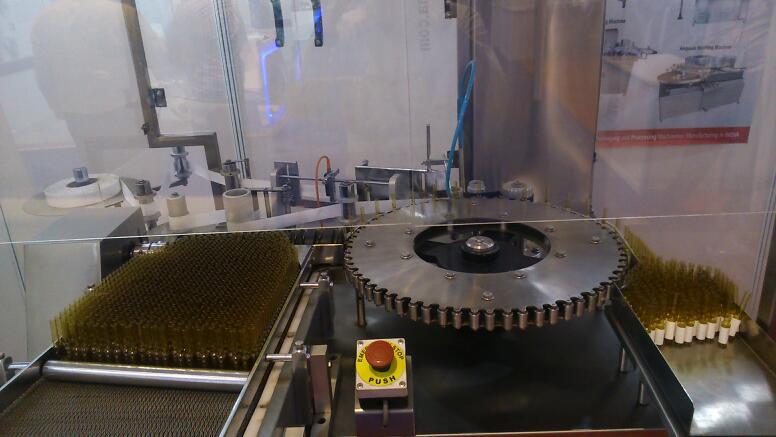

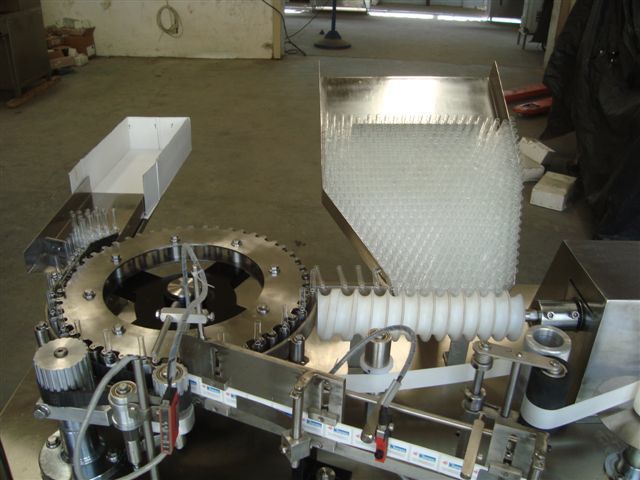

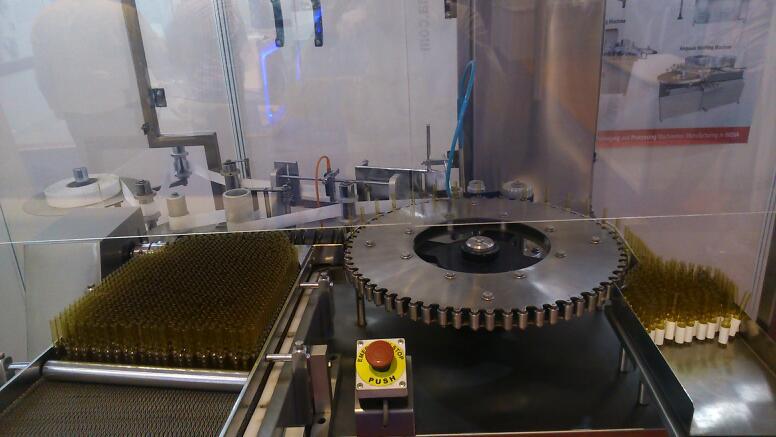

Automatic Ampoule Labelling Machine

Price 800000 INR/ Unit

Automatic Ampoule Labelling Machine Specification

- Material

- SS

- Computerized

- No

- Automatic Grade

- Automatic

- Control System

- Human Machine Interface

- Drive Type

- Electric

- Color

- Silver

- Warranty

- 1 year

Automatic Ampoule Labelling Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 30 Pieces Per Month

- Delivery Time

- 4-6 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Packing Only

- Main Export Market(s)

- South America, Western Europe, Middle East, Central America, Africa, Asia, Eastern Europe, North America, Australia

- Main Domestic Market

- All India

- Certifications

- CE & ISO Certified

About Automatic Ampoule Labelling Machine

SPECIFICATION OF THE EQUIPMENT MACHINES BASICS

| PARTICULAR | SPECIFICATION |

| Machine Name | Automatic Rotary Ampoule Sticker Labeling Machine |

| Model | Servo Based Machine |

| Production Speed | Upto 100 Containers per Minute (Speed Depends up on the length of label and diameter of product and Operator Skills). |

| Suitable for Products | Glass Ampoule |

| Application | Labeling on Straight Surface |

| Labels Requirement | Self Adhesive Sticker Labels in Roll Form having consistence 3 mm gaps between the 2 labels. |

| Label Material | Self Adhesive Paper Labels |

| Label Roll Outer Diameter | Maximum 300 mm |

| Label Core ID | 75 mm |

| Label Dispensing Accuracy | +1 mm |

| Working Height | 700 mm (+/-50 mm) |

| Machine Weight | Approx 300 Kgs |

| Machine Dimension | Approx 6 (L) x 6(W) x 8 (H) in Feet |

MACHINES MATERIAL OF CONSTRUCTION

| PARTICULAR | SPECIFICATION |

| Machine Main Base Frame | Stainless Steel 304 Pipe Structure |

| Machine Coverings | Complete in Stainless Steel 304 |

| Product Contact Parts | Stainless Steel 304 |

| Non Contact Parts | Stainless Steel / Mild Steel / Aluminum / Teflon (Whichever is applicable) |

| Star wheel | Stainless steel with Teflon/stainless steel roller |

| Feed worm | Teflon |

| Tray for in feed | Stainless Steel with chain type conveyor |

| Tray for outf eed | Stainless Steel |

| Bearings | SKF / Niche / Equivalent |

| Plating(Wherever Applicable) | Zinc / Hard Chrome / Blackening |

| Wrapping Belt | End Less Sponge Coated Wrapping Belt |

| Bottle Separation / Spacing Unit | Teflon Feed worm |

| Dispenser Rollers | Rubber Molded + Aluminum + Knurling Rollers |

| Dispenser Unit Up & Down | Screw Based UP & DOWN Assembly |

OPTIONAL FEATURE

- Label Roll Empty Machine Stop System with Alarm.

- Missing Label in Roll Machine Stop System with Alarm

- Special Label Sensor for sensing Transparent Film Labels which does not have any sensing mark on it.

- Option of Contact Coder, Hot Foil Coder, HP Cartridge Coder and Inkjet Coder with various speed ranges available.

- Toughened Glass or Acrylic Safety Cabinet for Machine.

- Tower Light showing the machine status / operation.

- Colour or Mono Touch Screen with PLC for machine operation and showing various error messages and information onisplay.

- Special Sensing system for checking missing label on product.

- Low Compressed Air Machine Stop with Alarm system for pneumatically o- operated coding system.

- Vision System for checking Barcode,presence or absence of Coding or pharma code on labels.

- Vision System with OCR system for checking coding on labels.

- Online pneumatically operated product rejection system.

- Poly carbonate Enclosure in Stainless steel Profile.

Lower Energy Consumption and Eco-Friendly Operation

This labelling machine incorporates cutting-edge technology to minimize energy consumption, resulting in reduced operational costs and a lighter environmental footprint. Its energy-efficient design ensures high output while maintaining low power usage, making it ideal for sustainable manufacturing environments concerned about energy savings.

Modern Touch Screen Controls and Simple Operation

Equipped with advanced touch screen interfaces, the machine provides straightforward and intuitive navigation for adjustments and monitoring. Operators can manage the labelling process with minimal training, thanks to the simple control mechanisms, which ensures efficiency and minimizes downtime during production runs.

High-Speed Performance and Versatility

With a robust stainless steel construction, the machine delivers industry-leading performance, reliably processing 60 to 120 ampoules per minute. Its high throughput capacity makes it suitable for pharmaceutical, cosmetic, and chemical industries in need of fast and consistent results without sacrificing quality or efficiency.

FAQs of Automatic Ampoule Labelling Machine:

Q: How does the Automatic Ampoule Labelling Machine enhance production efficiency?

A: The machine features high-speed labelling capabilities (up to 120 BPM), simple controls with a touch screen, and automatic grade functionality. These elements streamline operations, reduce manual intervention, and improve overall efficiency, leading to higher throughput without sacrificing accuracy.Q: What is the process for operating this ampoule labelling machine?

A: Operation is simplified via the integrated touch screen and Human Machine Interface or PLC control system. Users load the ampoules, set parameters, and start the automatic process. The machine handles labelling with minimal noise and intervention, thanks to its sophisticated control systems.Q: Where can this ampoule labelling machine be used?

A: The machine is ideal for pharmaceutical, cosmetic, and chemical manufacturing environments requiring precise and rapid ampoule labelling. It is distributed, exported, and supplied throughout India, making it accessible for varied industrial setups nationwide.Q: What are the benefits of choosing a machine made from stainless steel (SS)?

A: Stainless steel ensures durability, corrosion resistance, and excellent hygiene standards. It also contributes to the machines long life and ease of cleaning, which is crucial for industries with stringent safety and cleanliness requirements.Q: When is maintenance or servicing required for the machine?

A: Regular maintenance in line with manufacturer recommendations helps preserve high performance and efficiency. The included one-year warranty supports users against manufacturing defects, and periodic checks ensure smooth operation and longevity.Q: Does the machine provide environmentally friendly solutions?

A: Yes, the ampoule labelling machine is designed for lower energy consumption and high efficiency, ensuring reduced energy use and minimal environmental impact during labelling operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Labeling Machine Category

Stand Alone Label Applicator

Price 375000 INR / Unit

Minimum Order Quantity : 1 Unit

Control System : Human Machine Interface

Automatic Grade : Automatic

Computerized : No

Material : SS

Automatic Pallet Labelling Machine

Price 1200000 INR / Unit

Minimum Order Quantity : 1 Unit

Control System : Human Machine Interface

Automatic Grade : Automatic

Computerized : No

Material : SS

Automatic Rotary Sticker Labeling Machine

Price 750000 INR / Unit

Minimum Order Quantity : 1 Unit

Control System : Human Machine Interface

Automatic Grade : Automatic

Computerized : No

Material : SS

High Speed wet Glue Labeling Machine

Price 800000 INR / Unit

Minimum Order Quantity : 1 Unit

Control System : Human Machine Interface

Automatic Grade : Automatic

Computerized : No

Material : SS

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free