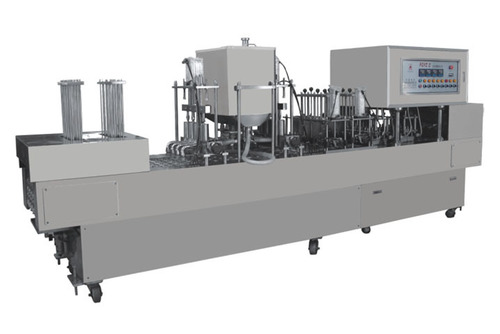

Empty Capsule Uploading Machine

MOQ : 1 Piece

Empty Capsule Uploading Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- India

- Payment Terms

- Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 30 Pieces Per Week

- Delivery Time

- 8 - 10 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box Packing only

- Main Domestic Market

- All India

- Certifications

- ISO and CE Certified

About Empty Capsule Uploading Machine

Specifications:-

- Suitable for all sizes of capsules.Easy to operate, high capacity. Low noise. Air pumpprovides compressed air, no need air source, no limitation on compressed air.

- It can be connected to capsule filling machine, automatic uploading.

- Hopper capacity:150 LTR.

- Uploading speed:8000 capsules/min

- Power supply: 220 V

- Dimension: 600 mm x 1100 mm

- Weight: 50 kg

Advanced Automation for High Productivity

Equipped with an automatic control mode, the Empty Capsule Uploading Machine dramatically increases processing speed and precision. Its computerized system ensures seamless operation and minimal manual intervention, ideal for pharmaceutical companies focusing on scalability and compliance with industry standards.

Customizable Design Tailored to Your Production

Clients can specify key parameters such as capacity, power, voltage, and overall dimensions. This level of customization ensures seamless integration into your existing production lines, regardless of your facilitys size or workflow requirements, enabling optimal productivity and resource management.

FAQs of Empty Capsule Uploading Machine:

Q: How does the Empty Capsule Uploading Machine work?

A: The machine uses automated mechanisms to efficiently load empty capsules into packaging equipment. Its computerized controls manage every stage of the process, minimizing manual handling and ensuring a consistent, accurate flow of capsules during pharmaceutical production.Q: What benefits does this machine offer for pharmaceutical manufacturers?

A: It improves operational efficiency by automating capsule uploading, reducing human error, and maintaining hygiene with its stainless steel design. The customizable capacity and voltage options allow manufacturers to match the machine to their specific needs, enhancing productivity and flexibility.Q: When should I consider installing this capsule uploading machine?

A: This machine is ideal when scaling up operations, seeking greater reliability in capsule loading, or aiming to comply with strict hygiene standards. It suits both new and established pharmaceutical packaging lines looking to boost output and streamline processes.Q: Where can this machine be integrated within my production facility?

A: It can be seamlessly connected to capsule filling and packaging systems, fitting into various production layouts due to the made-to-order dimensions. Its adaptability ensures it can become an integral part of most pharmaceutical manufacturing settings.Q: What is the typical process for ordering and installing the machine?

A: Clients discuss their specific requirements (capacity, voltage, dimensions), after which the manufacturer customizes the unit. After installation, support and training are provided to ensure smooth integration and operation within the clients facility.Q: How is the machine maintained and what warranty is provided?

A: Routine maintenance involves cleaning and periodic system checks, owing to the machines easy-to-clean stainless steel construction. A one-year warranty covers any manufacturing defects, and technical support is available throughout this period.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Automatic Packaging Machine Category

Linear Type Yougourt Cup Filling And Sealing Machine

Minimum Order Quantity : 1 Piece

Computerized : Yes

Material : Stainless Steel Alloy

Warranty : 1 year

Control System : PLC Control

Sainless Steel Soft Drink Production Line For Yoghurt Milk 5000 L/H

Minimum Order Quantity : 1 Piece

Computerized : Yes

Material : Stainless steel

Warranty : 1 year

Control System : PLC Control

Automatic double head tube filling machine

Minimum Order Quantity : 1 Piece

Computerized : No

Material : SS

Warranty : 1 Year

Control System : Human Machine Interface

Automatic Vial Filling Machine

Minimum Order Quantity : 1 Piece

Computerized : Yes

Material : Stainless Steel

Warranty : 1 year

Let's talk business

Please take a moment to complete this form and a business representative will get back to you swiftly

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free