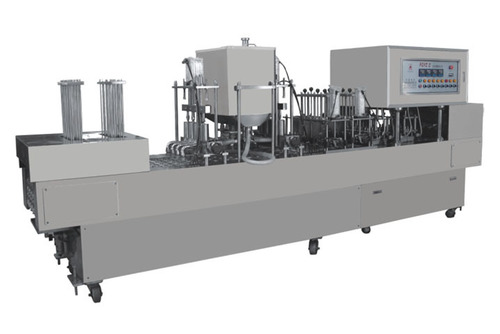

Automatic Vial Filling Machine

Automatic Vial Filling Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- India

- Supply Ability

- Piece

- Delivery Time

- 4 to 6 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Packing only

- Main Domestic Market

- All India

- Certifications

- ISO and CE Certified

About Automatic Vial Filling Machine

The incoming dry vials (sterilized and siliconized)are fed through the unscrambler and suitably guided on the moving delr in slat conveyor belt at the required speed of the correct placement below filling unit. T

Precision Engineering for Pharmaceutical Packaging

Designed for pharmaceutical environments, the Automatic Vial Filling Machine utilizes computerized control to deliver accurate dosage and minimize human error. Its automatic mode streamlines the packaging process, maintaining high hygiene standards and operational efficiency.

Robust Construction and Reliable Performance

With a stainless steel construction, the machine ensures corrosion resistance and product safety. The 1 H.P. motor and advanced control system allow continuous operation under high loads. The included warranty and after-sales support offer peace of mind for manufacturers and suppliers.

FAQs of Automatic Vial Filling Machine:

Q: How does the Automatic Vial Filling Machine operate?

A: The machine uses computerized controls for precise and automated filling, allowing operators to set parameters such as speed and vial size. Its automatic mode streamlines the entire filling process, enhancing productivity and reducing manual intervention.Q: What is the maximum capacity of vials the machine can fill per minute?

A: This model is capable of filling between 30 to 120 vials per minute, making it suitable for both medium and large-scale pharmaceutical production environments.Q: When should regular maintenance be performed on this vial filling machine?

A: Routine maintenance is recommended every six months, or as per the operational hours, to ensure optimal performance. Preventive care helps avoid downtime and extends the machines lifespan beyond the warranty period.Q: Where can the Automatic Vial Filling Machine be sourced in India?

A: The machine is available from authorized distributors, exporters, manufacturers, and suppliers across India. Customers can contact local representatives or request quotations for direct purchase or export.Q: What process does the machine follow during vial filling?

A: Each vial passes through a conveyor where it is automatically positioned and filled based on pre-set volume parameters. The computerized system monitors and controls the filling, capping, and output sequence for consistent, accurate results.Q: How can users benefit from the computerized and automatic features of this machine?

A: Computerized and automatic features ensure consistent filling accuracy, reduce the risk of contamination, and enhance throughput. These improvements result in lower operational costs and minimal product wastage, benefiting both manufacturers and consumers.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Automatic Packaging Machine Category

Linear Type Yougourt Cup Filling And Sealing Machine

Minimum Order Quantity : 1 Piece

Color : Stainless Steel Finished

Material : Stainless Steel Alloy

Computerized : Yes

Drive Type : Electric

Automatic Grade : Automatic

4X Tin Leak Detector

Minimum Order Quantity : 1 Piece

Color : Other

Material : Stainless steel

Computerized : No

Drive Type : Electric

Automatic Grade : Automatic

Plastic Cup Package Industrial Yogurt Making Machine 6 Heads 4000 L/H

Minimum Order Quantity : 1 Piece

Color : Other

Material : Stainless steel

Computerized : Yes

Drive Type : Electric

Automatic Grade : Automatic

5 Gallon Water Barrel Washing Filling Capping Machine

Minimum Order Quantity : 1 Piece

Color : Other

Material : Stainless Steel

Computerized : Yes

Drive Type : Electric

Automatic Grade : Automatic

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free