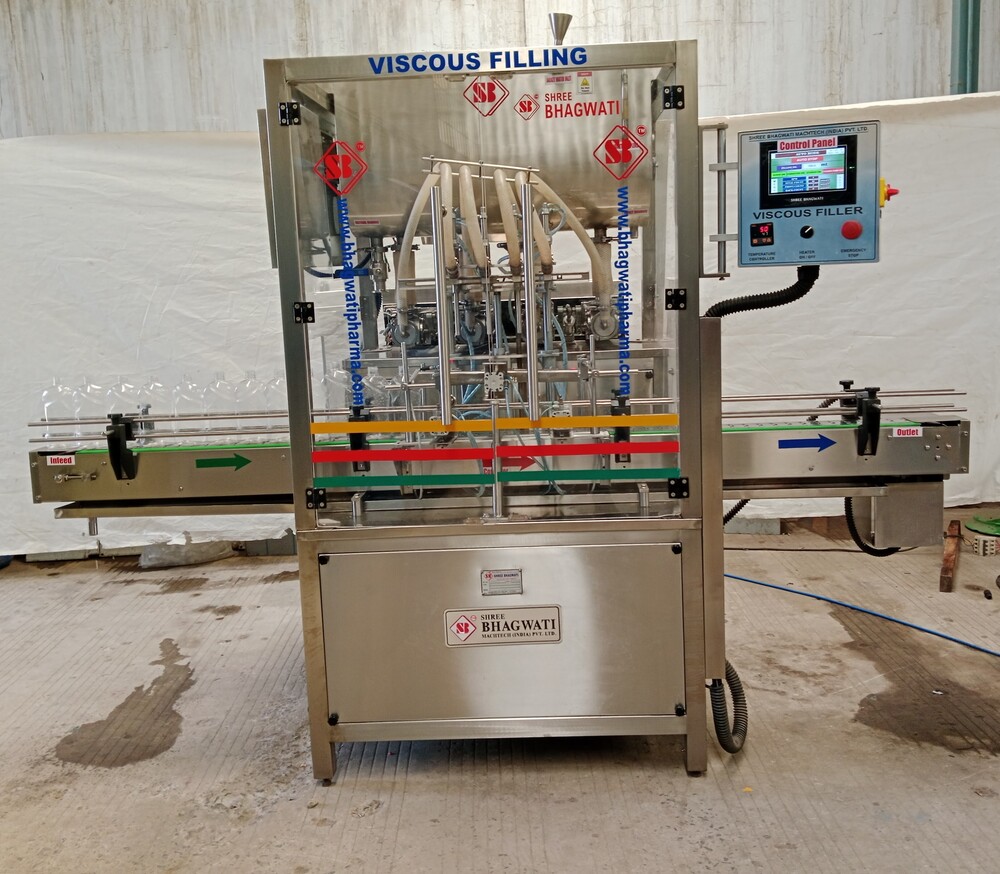

Bottle Filling Machine

Price 1200000 INR/ Unit

Bottle Filling Machine Specification

- Product Type

- Bottle Filling Machine

- Material

- SS

- Computerized

- No

- Automatic Grade

- Automatic

- Control System

- Human Machine Interface

- Drive Type

- Electric

- Feature

- ECO Friendly

- Warranty

- 1 Year

Bottle Filling Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Delivery Time

- 5-10 Days

About Bottle Filling Machine

Technical Specifications:

Power :440 Volts / 3 Phases / 50 Hz

Air Pressure :4 Kg

Fill Volume :100gm to 1000gm

Output :Up to 20-28 Bottle / Minute -depend on fill volume

Automatic Viscous Filling Machine:

SERVO + PLC based automatic viscous Filling machine online automatically with:

Servo Base Piston operating

Volume Adjustable from PLC NO Tools required

Multi Dose filling arrangement on request

Multi head dozers

Diving nozzles.

Shut off type nozzle for anti-drip.

SS conveyor with stop-release line automation

no-bottle-no- fill controls,

CIP mode for rinsing of product cylinders, valves and nozzles.

Ideally suited to fill viscous products like Ghee & lotions.

Adjustable guide rails on conveyor to accommodate different diameters of bottles/cans.

SS hopper.

Pneumatic cylinders for Bottle Stopper.

Adjustable diving depth depending on size of bottles/cans.

PLC + Touch Screen controlled panel for electrical controls.

Production counter on PLC.

PLC settings for varied volumes.

Volume adjustment facility for different pack volumes.

Height adjustment facility for different bottle sizes.

Optical/Proximity sensors to sense arrival of bottles to filling station.

Stoppers to accurately stop bottles/cans under the filling nozzle.

Accuracy ï0.25% to 0.5%

All contact parts SS316 and non contact parts SS304

Technical Specifications of Viscous Filling Machine

Machine Internationally proven high quality pneumatically + servo PLC operated piston filler with the latest technology fixed product cylinder (syringe) attached to pneumatic cylinder in one line, giving better life to filling syringe seals and hence no leakages which are observed in mechanically driven machines with oscillating cylinders.

Efficient Automatic Filling

Our Bottle Filling Machine automates the bottle filling process, reducing manual effort and ensuring consistent results. The electric drive paired with a Human Machine Interface allows operators to monitor and control the system seamlessly, making day-to-day operations more efficient. The use of stainless steel ensures longevity and resilience, even under rigorous industrial use.

Eco-Friendly and Durable Design

Engineered with eco-friendly features, this bottle filling machine minimizes resource consumption and environmental impact. Its robust stainless steel construction not only contributes to its durability but also keeps maintenance requirements low, making it a cost-effective solution for every business.

FAQs of Bottle Filling Machine:

Q: How does the automatic bottle filling machine operate?

A: This machine operates using an electric drive system with a Human Machine Interface, which automates the entire filling process. Operators input settings via the interface, and bottles are filled consistently without manual intervention.Q: What materials are used in constructing the bottle filling machine?

A: The bottle filling machine is constructed from high-grade stainless steel, ensuring great resistance to corrosion and wear over time, making it suitable for rigorous industrial environments.Q: When should I use this bottle filling machine in my production line?

A: This machine is ideal for use when high-volume and consistent bottle filling is required, streamlining the process and reducing labor costs in beverage, pharmaceutical or cosmetic industries.Q: Where is the machine manufactured and supplied?

A: The bottle filling machine is manufactured in India and supplied across various regions by reputable distributors, exporters, and manufacturers, ensuring accessibility for businesses nationwide.Q: What is the process for operating and maintaining the machine?

A: To operate, set your filling requirements on the Human Machine Interface and start the automatic cycle. Regular cleaning and routine check-ups ensure optimal performance and longevity of the stainless steel components.Q: How does using this bottle filling machine benefit my business?

A: By automating bottle filling, this machine increases production speed, improves accuracy, minimizes waste, and lowers labor costs. Its eco-friendly design also supports sustainable business practices.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Automatic Lotion Filling Machine Category

Rotary Filling, Stoppering And Capping Machine

Price 750000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Warranty : 1 year

Product Type : Rotary Filling, Stoppering and Capping

Drive Type : Electric

Automatic Piston Pump Filling Machine

Price 1200000 INR / Unit

Minimum Order Quantity : 1 Piece

Automatic Grade : Automatic

Warranty : 1 Year

Product Type : Piston Pump Filling Machine

Drive Type : Electric

Automatic Two head PLC Based Liquid Filling Machine

Price 600000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Warranty : 1 year

Product Type : Automatic Filling Machine

Drive Type : Electric

High Speed Rotary High Viscous Liquids Filling Machine

Minimum Order Quantity : 1 Piece

Automatic Grade : Automatic

Warranty : 1 Year

Product Type : High Speed Viscous Liquids Filling

Drive Type : Electric

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free