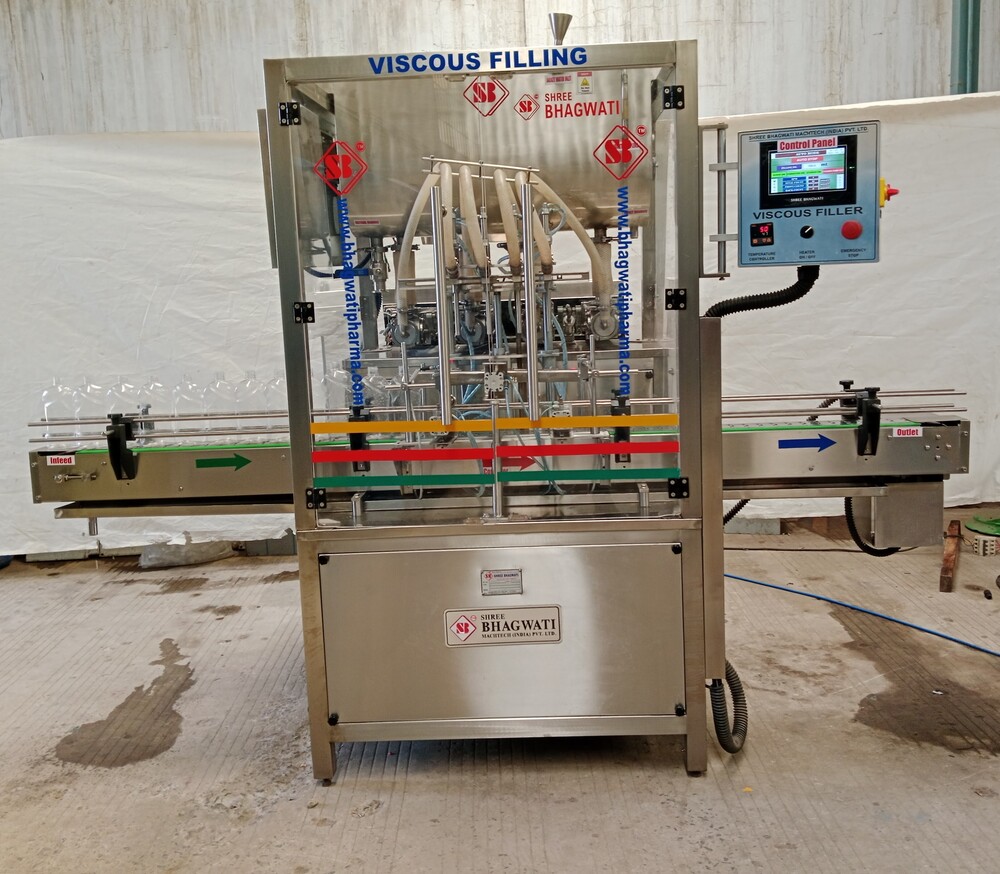

Automatic Piston Pump Filling Machine

Price 1200000 INR/ Unit

Automatic Piston Pump Filling Machine Specification

- Product Type

- Piston Pump Filling Machine

- Material

- Stainless Steel

- Application

- Beverage, Chemical, Medical, Food

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Control

- Drive Type

- Electric

- Voltage

- 420 V 50/60 Hz 3.2 Kw Watt (w)

- Weight (kg)

- 400 Kg Kilograms (kg)

- Dimension (L*W*H)

- L1600*W1200*H1800 (L*W*Hmm) Millimeter (mm)

- Capacity

- 1000-6,000 BPH Kg/hr

- Feature

- Lower Energy Consumption, ECO Friendly, High Performance, Low Noise, High Efficiency, Stable Performance, Simple Control

- Color

- Other

- Warranty

- 1 Year

Automatic Piston Pump Filling Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- India

- Supply Ability

- Piece

- Delivery Time

- 4-6 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Packing only

- Main Domestic Market

- All India

- Certifications

- ISO and CE Certified

About Automatic Piston Pump Filling Machine

Feature:

- No bottle no filling

- Drip-proof filling nozzle

- Easy cleaning structure

- Jacket hopper for hot filling products

- Servo motor driven, HMI control

Technical Parameter:

| Item | Piston pump filling machine |

| Filling nozzle | 2, 4, 6, 8, 10, 12, 16 |

| Filling system | Piston pump |

| Filling range | 100-1,000 g; 1000-5000 ml |

| Filling speed | 1000-6,000 bottles /hour |

| Filling precision | +1% |

| Power | 380V 50/60Hz 3.2Kw |

| Air pressure range | 0.6-0.8Mpa |

| Weight | 400Kg |

| Machine side | L1600*W1200*H1800 (L*W*Hmm) |

High-Efficiency, Versatile Filling Solution

This filling machine accommodates a diverse range of products, from beverages to chemicals and pharmaceuticals. Its automatic piston system ensures accurate, high-speed filling, while the PLC control streamlines operation. Optimized for low energy consumption and minimal noise, its a sustainable choice for modern production lines seeking enhanced efficiency and simple maintenance.

Robust Build with Eco-Friendly Performance

Manufactured from top-grade stainless steel, this filling machine offers both durability and resistance to corrosion. Its eco-friendly design reduces energy consumption, making it an environmentally conscious solution without sacrificing productivity. Quiet operation allows for smoother work environments, contributing to better overall production safety and comfort.

FAQs of Automatic Piston Pump Filling Machine:

Q: How does the Automatic Piston Pump Filling Machine ensure accurate filling?

A: This machine utilizes a piston-driven system managed by computerized PLC control, providing highly precise measurement and dispensing of liquids. This mechanism ensures consistent fill levels, minimizing waste and product variation.Q: What types of products can be processed with this filling machine?

A: The machine is suitable for a broad spectrum of applications, including beverages, chemicals, pharmaceuticals, and food products. Its robust stainless steel construction and adjustable filling parameters accommodate different viscosities and container types.Q: Where can this filling machine be installed and who can use it?

A: With a compact footprint and stable performance, the machine can be integrated into production lines at distribution centers, manufacturing plants, export hubs, and supplier facilities across India. It suits both new facilities and upgrades of existing lines.Q: What is the control process for operating the machine?

A: Operation is simplified via a PLC-based control system, allowing users to manage filling speed, volume, and cycle times through an intuitive interface. The automatic grade ensures minimal manual intervention, reducing the risk of errors.Q: When should routine maintenance on this machine occur?

A: Regular maintenance is recommended as outlined in the manufacturers guide, typically every few months depending on usage intensity. The stainless steel build helps reduce maintenance frequency by resisting wear and corrosion.Q: What are the key benefits of this filling machine over manual options?

A: Compared to manual filling, this automatic machine delivers higher speed, improved accuracy, and consistent output. It also reduces labor costs, lowers energy usage, and enhances workplace safety through quieter operation and reliable controls.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Automatic Lotion Filling Machine Category

2 Head Automatic Lotion Filling Machine

Price 900000 INR / Unit

Minimum Order Quantity : 1 Unit

Control System : PLC Control

Automatic Grade : Automatic

Warranty : 1 year

Product Type : Automatic Filling Machine

Automatic Two head PLC Based Liquid Filling Machine

Price 600000 INR / Unit

Minimum Order Quantity : 1 Unit

Control System : PLC Control

Automatic Grade : Automatic

Warranty : 1 year

Product Type : Automatic Filling Machine

High Speed Rotary High Viscous Liquids Filling Machine

Minimum Order Quantity : 1 Piece

Control System : PLC Control

Automatic Grade : Automatic

Warranty : 1 Year

Product Type : High Speed Viscous Liquids Filling

Flowmatic Plc Base Auto Volume Adjustable Eight Head Liquid Filling Machine

Minimum Order Quantity : 1 Piece

Control System : PLC Control

Automatic Grade : Automatic

Warranty : 1 year

Product Type : Automatic Filling Machine

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS