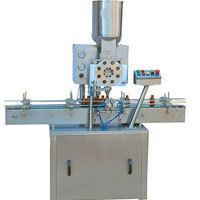

Automatic Vial Powder Filling Machine

Automatic Vial Powder Filling Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- India

- Supply Ability

- Piece

- Delivery Time

- 3 -4 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Packing Only

- Main Domestic Market

- All India

- Certifications

- ISO and CE Certified

About Automatic Vial Powder Filling Machine

The sterilized powder is stored in powder hopper is agitated by pair of mechanical agitators for maintaining consistency and uniform bulk density. The powder wheel having eight ports rotates at the pre determined speed below the powder hopper with practically no clearance. Powder wheel consist of Piston in each port and behind the powder wheel vacuum plate is provided there is no clearance between powder wheel and vacuum plate due to back spring pressure. Precise volume of powder is sucked in to the port of powder wheel during vacuum according to the piston length different fill size can be achieved. The excess powder is doctored off by a doctor blade. Doctor blades can be adjusted from outside also without removing powder hopper.

High-Speed and Accurate Vial Filling

Achieve unmatched productivity with our automatic vial powder filling machine, which can process between 30 and 240 vials per minute. The machines computerized controls enable precise dosing, minimizing wastage while maximizing efficiency. Its robust design ensures consistent performance across demanding pharmaceutical environments.

Customizable for Diverse Application Needs

Built using high-quality stainless steel, this packaging solution is tailored to fit user-specific voltage, power, and size requirements. The automatic vial filling machine can be configured as per operational demand, making it ideal for pharmaceutical manufacturers, distributors, exporters, and suppliers throughout India.

Reliability with Comprehensive Warranty

Purchase with confidenceyour investment is protected by a one-year warranty covering manufacturing and performance. This guarantees minimal interruption and secure operations for pharmaceutical packaging, supported by reliable after-sales service.

FAQs of Automatic Vial Powder Filling Machine:

Q: How does the automatic vial powder filling machine enhance the pharmaceutical packaging process?

A: The machine automates powder filling into vials using computerized controls, which increases speed and accuracy, ensures consistent dosage, and significantly reduces manual handling and associated errors.Q: What materials are used in the construction of this vial filling machine?

A: The entire machine is constructed using high-grade stainless steel, offering durability, corrosion resistance, and easy cleaning suitable for sanitary pharmaceutical environments.Q: When is this machine suitable for use in pharmaceutical production lines?

A: It is ideal for use when high throughput, precision filling, and automated packaging are required, particularly in large-scale or batch pharmaceutical production environments.Q: Where can the automatic vial powder filling machine be installed and who can benefit from it?

A: This machine can be installed in pharmaceutical manufacturing facilities across India and benefits manufacturers, exporters, suppliers, and distributors who seek efficient and reliable vial filling solutions.Q: What is the process for operating and maintaining this machine?

A: Operation involves loading empty vials, setting computer controls for dosage, and monitoring automated filling. Maintenance includes routine cleaning, inspection, and adherence to the one-year warranty support for optimal performance.Q: What are the usage advantages of having a computerized and automatic control mode?

A: Computerized automatic control offers precise filling, real-time monitoring, error reduction, and efficient batch processing, resulting in higher productivity and better compliance with industry standards.Q: What are the main benefits of choosing this stainless steel finished machine for pharmaceutical packaging?

A: The benefits include robust build quality, hygienic surfaces, high-speed operation, accuracy in powder dosing, durability, easy customization, and comprehensive after-sales support.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Powder Filling Machine Category

Automatic Single head Powder Filling Machine

Price 600000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Warranty : 1 year

Control System : PLC Control

Material : Stainless steel

Rotary Monoblock Dry Syrup Powder Filling Machine

Price 1500000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Warranty : 1 Year

Control System : Human Machine Interface

Material : SS

Powder Filling and Powder Filler Machine

Price 550000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Warranty : 1 Year

Control System : Human Machine Interface

Material : SS

Dry Syrup Powder Filling Machine

Minimum Order Quantity : 1 Piece

Automatic Grade : Automatic

Warranty : 1 Year

Control System : Human Machine Interface

Material : SS

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free