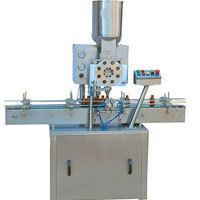

Automatic Two Head Powder Filling Machine

Price 1100000 INR/ Unit

Automatic Two Head Powder Filling Machine Specification

- Type

- Filling Machine

- Material

- Stainless steel

- Auxiliary Packaging Machine Type

- Other

- Capacity

- 30-35 BPM Kg/hr

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Control

- Drive Type

- Electric

- Voltage

- As per the client required Watt (w)

- Warranty

- 1 year

Automatic Two Head Powder Filling Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- India

- Supply Ability

- 30 Units Per Week

- Delivery Time

- 3-4 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Packing Only

- Main Export Market(s)

- South America, Western Europe, Middle East, Central America, Asia, Eastern Europe, North America, Australia, Africa

- Main Domestic Market

- All India

- Certifications

- ISO and CE Certified

About Automatic Two Head Powder Filling Machine

Operation:

The dried bottles are fed through the infeed Turn Table on the infeed SS/ Delrin conveyor belt at the required speed for feeding. There are 4 Filling Heads and hence bottle reaches under the first filling head, it is held by the pneumatic bottle holder. Immediately it is be sensed by the bottle sensor and gives signals to magnetic clutch to start to rotate which is mounted on auger shaft. It will fill the desired amount of powder to the bottle through auger, where rotation time is set in the Timer. After filling of first bottle pneumatic bottle holder releases the first bottle to move on conveyor. At the same time second bottle also moves along with the first bottle in empty condition. In the second filling head same operation is performed but this second bottle gets filled and first bottle moves further for next operation.

Technical Specifications:

| Model | SBAF-80 |

| Direction | Left To Right. |

| Output (SBAF-80) | Up to 35 Bottle per minute - Depend on fill size |

| Fill Capacity | 200gm-1000gm (with different set of Auger and funnel) Fill range depending upon Bottle opening and bulk density of powder. |

| Powder Accuracy | ± 2% |

| Electrical Supply | 2.00 HP For Main Drive. 0.25 HP for conveyor |

| Power Requirement | 440 Volts, 3 Phase (4 wire System) 50 Hz. |

| Height of Conveyor | Adjustable from 800 To 850 MM |

| Pneumatic Air | Filtered, oil free, sterile low pressure AIR at 5kg/cm2 |

High-Performance Technology

This powder filling machine is engineered with advanced computerized controls that guarantee accuracy in filling quantities. The PLC control system automates the filling process, allowing operators to manage production efficiently and focus on other critical tasks. Its durable stainless steel construction provides resistance to corrosion, ensuring low maintenance and longstanding reliability.

Flexible Operation and Support

Tailored to meet different production requirements, the machines voltage can be adjusted based on the clients specifications. The automatic grade and electric drive offer seamless integration into existing production lines. As a leading distributor, exporter, manufacturer, and supplier, our support network throughout India provides swift installation, training, and after-sales assistance.

FAQs of Automatic Two Head Powder Filling Machine:

Q: How does the Automatic Two Head Powder Filling Machine ensure precise powder filling?

A: The machine uses a computerized PLC control system that regulates dosing and filling measurements, ensuring each container receives the exact quantity specified. This minimizes wastage and guarantees product consistency.Q: What is the process for installing this machine at my facility?

A: Installation involves placing the machine in your designated production area, connecting the electric drive, and calibrating the voltage as per your requirements. Our technical team will provide setup support, testing, and operator training to ensure smooth operation.Q: When is this powder filling machine suitable for use?

A: This machine is best suited for large-scale, continuous production environments that handle powder products and require high-speed, automatic filling. Its ideal for industries like pharmaceuticals, food processing, or chemicals.Q: Where can I purchase, install, or get support for this machine in India?

A: As a distributor, exporter, manufacturer, and supplier in India, we offer nationwide service. You can reach out to our sales team to purchase, arrange installation, and access maintenance and warranty support across major cities and industrial zones.Q: What are the key benefits of using a stainless steel, fully automatic filling machine?

A: Stainless steel construction enhances hygiene and resists corrosion, making it suitable for stringent industrial requirements. Full automation and computerized controls boost productivity, reduce manual errors, and improve operational efficiency.Q: How is the powder filling operation handled by the PLC control system?

A: The PLC system manages the entire filling sequence, from container alignment to dosing and filling, offering user-friendly parameter adjustments for different powders and quantities. This ensures smooth, accurate, and repeatable operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Powder Filling Machine Category

Double Head Auger Type Powder Filling Machine

Price 1200000 INR / Unit

Minimum Order Quantity : 1 Piece

Material : SS

Automatic Grade : Automatic

Computerized : No

Control System : Human Machine Interface

Auger Filling Machines

Price 600000 INR / Unit

Minimum Order Quantity : 1 Piece

Material : Stainless steel

Automatic Grade : Automatic

Computerized : Yes

Control System : Human Machine Interface

Dry Syrup Powder Filling Machine

Minimum Order Quantity : 1 Piece

Material : SS

Automatic Grade : Automatic

Computerized : No

Control System : Human Machine Interface

VFFS Machine With Volume Metric Cup Filler for Powder Packing

Price 1600000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless steel

Automatic Grade : Automatic

Computerized : Yes

Control System : PLC Control

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free