Automatic Single Head Wad Inserting Machine

Automatic Single Head Wad Inserting Machine Specification

- Type

- Sealing Machines

- Material

- Stainless steel

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Control

- Drive Type

- Electric

- Power

- As per the client required Watt (w)

- Voltage

- As per the client required Watt (w)

- Warranty

- 1 year

Automatic Single Head Wad Inserting Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- India

- Payment Terms

- Days after Acceptance (DA), Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 30 Pieces Per Week

- Delivery Time

- 4-6 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Packing Only

- Main Domestic Market

- All India

- Certifications

- ISO and CE Certified

About Automatic Single Head Wad Inserting Machine

| Output | Up to 20-30 Caps per minute (depend on cap size | |

| Direction of Movement | Left to Right. | |

| Electrical Specification | Main Motor | 2 HP max |

| Cap Feeding Bowl | 10 amps | |

| Working Height | 700 to 900 mm. Adjustable | |

| Change parts required | (A) Cap: Vibrating Bowl, Chute, Star Wheel. (B) Wad: Magazine, Pusher, Star wheel, Inserting Plate. | |

Advanced Automation for Sealing Efficiency

Featuring a computerized PLC control system, this automatic grade machine provides seamless wad insertion into containers, streamlining the sealing process. Its electric drive ensures operation stability, while tailored voltage and power options fit diverse industrial requirements.

Robust Stainless Steel Construction

Crafted from premium stainless steel, the machine exhibits outstanding resistance to corrosion and heavy industrial wear, ensuring extended performance. Its sturdy build supports continuous operation in demanding production environments.

FAQs of Automatic Single Head Wad Inserting Machine:

Q: How does the Automatic Single Head Wad Inserting Machine improve the sealing process?

A: This machine automates the wad insertion step, reducing manual labor and ensuring uniform placement in containers. The PLC-controlled system maximizes accuracy and boosts speed for large-scale sealing applications.Q: What materials are used in the construction of this sealing machine?

A: The machine is made from high-grade stainless steel, which guarantees durability, prevents corrosion, and supports sustained use in fast-paced industrial settings.Q: When should I consider upgrading to an automatic wad inserting machine?

A: Upgrading is recommended when you need faster output, consistent sealing quality, or aim to reduce human error and labor costs in your packaging process.Q: Where can I purchase this machine in India?

A: You can buy this machine from authorized distributors, exporters, manufacturers, and suppliers throughout India. They provide end-to-end support including installation and after-sales services.Q: What are the benefits of using a PLC-controlled, computerized machine for wad insertion?

A: PLC control enhances precision, repeatability, and efficiency. Computerized operation allows easy adjustments, quick troubleshooting, and real-time monitoring, optimizing overall productivity.Q: How is the machine powered and can its specifications be customized?

A: The machine operates on an electric drive, with voltage and power specifications customizable based on client requirements, ensuring compatibility with varying industrial setups.Q: What kind of warranty and support does the manufacturer provide?

A: This machine comes with a one-year warranty, covering manufacturing defects and essential repairs. Suppliers also offer comprehensive after-sales support and routine maintenance services.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Automatic Packaging Machine Category

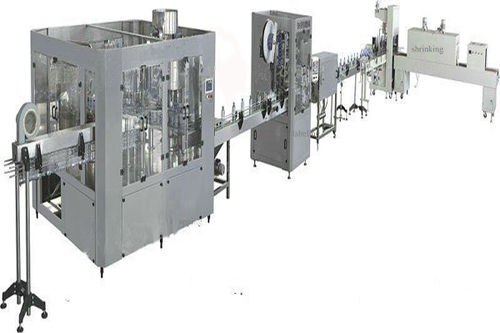

Automatic Juice Production Line

Minimum Order Quantity : 1 Piece

Warranty : 1 Year

Material : Stainless Steel

Computerized : Yes

Voltage : As per the client required Volt (v)

Automatic Tablet/ Capsule Filling Machine

Price 1100000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Warranty : yes

Material : stainless steel

Computerized : Yes

Voltage : as per customer required Watt (w)

Automatic 24 BPM Rinsing, Filling and Capping Machine

Minimum Order Quantity : 1 Piece

Warranty : 1 year

Material : SS

Computerized : Yes

Voltage : As Per the client required Watt (w)

Turn Table Machine

Minimum Order Quantity : 1 Piece

Warranty : 1 year

Material : Stainless steel

Computerized : Yes

Voltage : 220 Volt Volt (v)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free