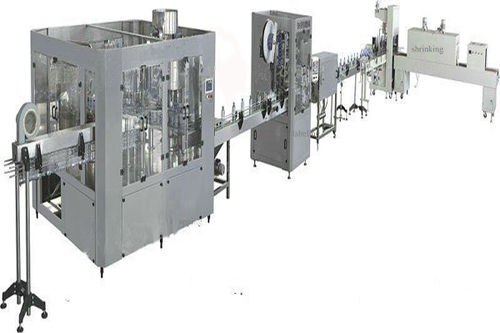

Automatic Juice Production Line

Automatic Juice Production Line Specification

- Type

- Packaging Line

- Material

- Stainless Steel

- Auxiliary Packaging Machine Type

- Other

- Capacity

- As per the client required Kg/hr

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Control

- Drive Type

- Electric

- Power

- As per the client required Volt (v)

- Voltage

- As per the client required Volt (v)

- Weight (kg)

- 15000 kg Kilograms (kg)

- Dimension (L*W*H)

- In Inches Inch (in)

- Color

- Other

- Warranty

- 1 Year

Automatic Juice Production Line Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- India

- Payment Terms

- Letter of Credit (L/C), Telegraphic Transfer (T/T), Letter of Credit at Sight (Sight L/C), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 10 Pieces Per Week

- Delivery Time

- 4-6 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Packing only

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia

- Main Domestic Market

- All India

- Certifications

- ISO and CE Certified

About Automatic Juice Production Line

Technical Specification:-

| Model | SB-04 | SB-06 | SB-08 | SB-10 | SB-12 | SB-1-12 | SB-15 | SB-20 |

| Number of washing, | 2012-12-4 | 18-18-6 | 24-24-8 | 32-32-10 | 40-40-12 | 50-50-12 | 60-60-15 | 80-80-20 |

| Production | 2000- | 5000- | 8000- | 12000- | 16000- | 20000- | 25000- | 35000- |

| Motor power(kw) | Main | Main | Main | Main | Main | Main | Main | Main |

| Overall dimensions (mm) | 2400 x | 2600 x | 3100 x | 3800 x | 4600 x | 5450 x | 6500 x | 76800 x |

| Weight (kg) | 2500 | 3500 | 4500 | 6500 | 8500 | 9800 | 12800 | 15000 |

Advanced Control System for Precision

Equipped with a cutting-edge PLC control system, the automatic juice production line ensures accurate monitoring and regulation throughout production. Computerized functions enhance reliability and efficiency, minimizing human intervention and reducing operational errors.

Customizable Design for Diverse Needs

The juice production line is tailored to match each clients specific capacity, power, and voltage requirements. Its robust stainless steel construction and versatile dimension options make it suitable for various juice products and packaging types, accommodating small to large operations.

Unmatched Durability and Safety

Built with high-quality stainless steel, the production line is corrosion-resistant, easy to sanitize, and designed for long-term use. Compliance with industry standards ensures safe food processing while maintaining a high level of product integrity in every batch.

FAQs of Automatic Juice Production Line:

Q: How does the PLC control system enhance the juice production process?

A: The PLC control system provides automated regulation and precise control over each step of juice processing, from extraction to packaging. This automation boosts production efficiency, improves product consistency, and reduces human error.Q: What is the capacity range of the automatic juice production line?

A: The capacity of the production line is fully customizable, allowing adjustment to the clients required kilograms per hour. This flexibility ensures suitability for both small and large-scale juice manufacturing setups.Q: When can maintenance be scheduled for the production line?

A: Routine maintenance can be planned at intervals that match your operational needs. The computerized system can assist in scheduling and alerting for regular check-ups to maximize uptime and prevent unexpected breakdowns.Q: Where can the juice production line be installed?

A: This production line can be installed in manufacturing facilities, beverage factories, or any industrial space equipped with the necessary electrical supply. The dimensions are customizable to fit your specific facility layout.Q: What is the typical process flow in the juice production line?

A: The process usually involves raw fruit intake, washing, extraction, filtration, pasteurization, packaging, and final product output. All stages are managed automatically for optimal efficiency and product quality.Q: How do users operate and monitor the production line?

A: Users interact with the system via a computerized interface, enabling real-time monitoring, adjustments, and diagnostics. The user-friendly controls are designed for ease of operation and quick troubleshooting.Q: What are the benefits of using this automatic juice production line?

A: Key benefits include streamlined operations, high productivity, consistent product quality, reduced labor costs, and easy expansion. The stainless steel construction ensures hygiene and durability, with a one-year warranty backing operational reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Automatic Packaging Machine Category

Automatic Carton Opening Machine

Minimum Order Quantity : 1 Piece

Warranty : 1 Year

Control System : PLC Control

Material : Stainless Steel

Computerized : Yes

Automatic Two Head Liquid Vial Filling with Rubber Stoppering Machine

Minimum Order Quantity : 1 Piece

Warranty : 1 Year

Control System : Human Machine Interface

Material : SS

Computerized : No

Monoblock Single Head Mosquito Repellent Filling and Capping Machine

Minimum Order Quantity : 1 Piece

Warranty : 1 year

Control System : PLC Control

Material : Stainless steel

Computerized : Yes

Automatic Tube Filling Sealing machine

Price 400000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Warranty : yes

Control System : PLC Control

Material : stainless steel

Computerized : Yes

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free