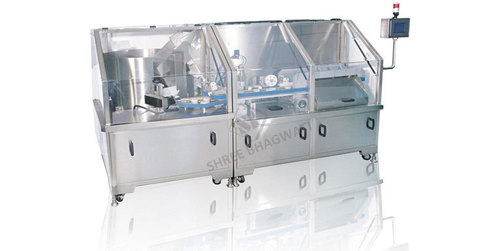

Automatic High Speed Unscrambler Machine

Automatic High Speed Unscrambler Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- India

- Supply Ability

- 30 Pieces Per Week

- Delivery Time

- 8-10 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box Packing Only

- Main Domestic Market

- All India

- Certifications

- ISO and CE Certified

About Automatic High Speed Unscrambler Machine

Description:-

Shree Bhagwati in-line machines are universally-suited for bottle production line in all packaging industries, most notably in: beverage, dairy, water, juice, food, household products, personal care, pharmaceutical, motor oil and bottle decorating. automatic bottle unscrambler system, automatic high speed bottle unscrambler, linear bottle unscramblers, plastic bottles unscrambler machine, linear and rotary bottle unscramblers and automatic bottle unscrambler for bottle production line.

bottle unscramblers that are used to automatically feed empty containers into the production line. The bottle unscramble in line machine sare universally-suited for high speed production line in all packaging industries, mostly high speed with less manually or manpower industry like feed empty containers unscramble machine to beverage, food, personal care and home care, motor oil and bottle decorating.

|

Capacity |

About 100 Bottles/min |

|

Bottle size range |

Diameter 25-100mm |

|

Bottle height |

45 - 200 mm (min. body height: 45 mm) |

|

Total power |

1.5Kw |

|

Power source |

380/220V, 50/60 Hz, three or two phase with separate ground. |

|

Current |

2.5A |

|

Machine dimensions |

L. 2665x W. 1341 x H. 1780 mm |

|

Weight |

800Kgs |

Precision Engineering for Versatile Operations

Manufactured in India using high-quality stainless steel, this Automatic High Speed Unscrambler Machine is ideal for distributors, exporters, and manufacturers seeking a reliable solution. Its robust design ensures longevity and consistent high-speed performance across a range of industrial applications. The flexibility in dimension, voltage, and power allows effortless integration into existing production ecosystems.

Seamless Automation and Efficient Workflow

Thanks to its computerized control mode, the unscrambler delivers error-free, rapid operation. Operators benefit from easy setup and intuitive automationfreeing staff to focus on higher-value tasks. The system efficiently unscrambles and orients containers or items for downstream processing, making it invaluable for high-output environments where speed and reliability are paramount.

FAQs of Automatic High Speed Unscrambler Machine:

Q: How does the Automatic High Speed Unscrambler Machine operate in a production line?

A: The machine utilizes advanced computerized controls to automatically unscramble and arrange products for efficient downstream processing. It seamlessly integrates with packaging or assembly lines, reducing manual handling and ensuring rapid, organized throughput.Q: What customizations are available for this unscrambler machine?

A: Capacity, voltage, power specifications, and dimensions can all be tailored to specific client requirements. This ensures compatibility with different production needs and local electrical standards.Q: When should this machine be used for optimal benefits?

A: The machine is best utilized in high-speed packaging, bottling, or assembly operations where large volumes need sorting quickly and accurately. Its automatic operation ensures enhanced productivity in demanding industrial environments.Q: Where is the Automatic High Speed Unscrambler Machine manufactured and supplied from?

A: The machine is manufactured, supplied, distributed, and exported from India, providing accessible support and efficient delivery throughout domestic and international markets.Q: What is the process for installing and setting up the machine?

A: Upon delivery, clients can follow the provided installation guide or request on-site assistance. The machines modular design and adjustable settings allow for straightforward integration into existing lines, minimizing downtime.Q: How does using this machine benefit industrial operations?

A: Automating the unscrambling process reduces labor costs, eliminates bottlenecks, and enhances overall workflow efficiency. Stainless steel construction assures durability, while computerization minimizes errors and maintenance needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Automatic Packaging Machine Category

Automatic Bottle Unscramble For Plastic Bottle

Price nan INR

Minimum Order Quantity : 1 Piece

Material : Stainless Steel

Computerized : Yes

Drive Type : Electric

Automatic Grade : Automatic

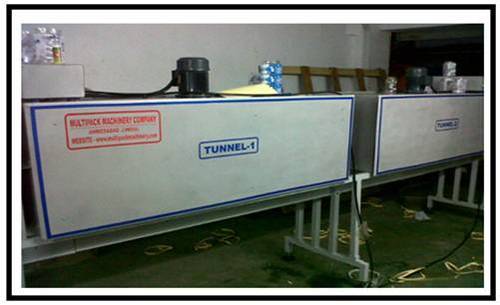

Shrink Tunnel Machine With Conveyor

Minimum Order Quantity : 1 Piece

Material : Stainless steel

Computerized : No

Drive Type : Electric

Automatic Grade : Automatic

Semi Automatic Self Adhesive Sticker Labelling Machine

Price 250000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steal

Computerized : Yes

Drive Type : Electric

Automatic Grade : SemiAutomatic

Online Injectable Vial Inspection Machine

Minimum Order Quantity : 1 Piece

Material : Stainless steel

Computerized : Yes

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free