Semi Automatic Self Adhesive Sticker Labelling Machine

Price 250000 INR/ Unit

Semi Automatic Self Adhesive Sticker Labelling Machine Specification

- Type

- Labeling Machines

- Material

- Stainless Steal

- Auxiliary Packaging Machine Type

- Other

- Computerized

- Yes

- Automatic Grade

- Semi-Automatic

- Control System

- PLC Control

- Drive Type

- Electric

- Warranty

- 1

Semi Automatic Self Adhesive Sticker Labelling Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- India

- Payment Terms

- Cash Against Delivery (CAD), Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Days after Acceptance (DA), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 30 Units Per Week

- Delivery Time

- 4-6 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden packing Only

- Main Domestic Market

- All India

- Certifications

- ISO and CE Certified

About Semi Automatic Self Adhesive Sticker Labelling Machine

Technical Specifications

| Model | SBSL - 60 |

| Label Height : | 8 mm to 70 mm Standard* |

| Label Length : | 12 mm Minimum |

| Label Roll Dia. : | 300 mm |

| Core Dia. : | 75/76 mm |

| Gap Between two Labels : | Approx. 3 mm |

| Product Diameter : | 15 mm to 70 mm* |

| Electrical : | 220 VAC Single Phase Power Supply (50/60 Hz) |

| Power : | 1.5 Amp. |

| Capacity : | 0.75 Kw |

| Speed : | Up to 10-15 BPM(depending on Product and Label Size) |

| Conveyor height : | 830-940 mm |

| Overall dimension : | 915 mm(L) X 870 mm(W) X 900 mm (H) |

| Machine Direction of Movement : | Left to Right from operator side |

Advanced PLC Control System

Outfitted with a PLC control system, the machine delivers precise label placement and automated adjustments for reliable operation. The computerized controls enable easy customization of labeling parameters, ensuring consistent quality across different products. This feature minimizes manual intervention, streamlining the labeling process for enhanced productivity.

Durable Stainless Steel Construction

Built from premium stainless steel, this labeling machine offers durability and resistance to corrosion, making it ideal for industrial environments. Its robust build ensures longevity, safety, and minimal maintenance, reducing operation downtime. The high-quality construction also helps maintain hygiene standards in food and pharmaceutical applications.

FAQs of Semi Automatic Self Adhesive Sticker Labelling Machine:

Q: How does the semi-automatic self adhesive sticker labelling machine operate?

A: The machine operates by semi-automatically applying self-adhesive stickers to products placed on its platform. Users load the item and initiate the process using electric controls and PLC, ensuring precise label placement with minimal human input.Q: What are the key benefits of using a computerized PLC control system in this labelling machine?

A: A computerized PLC control system offers superior accuracy, customizable settings, and consistent labeling results. It also reduces manual errors, enhances productivity, and simplifies troubleshooting through intelligent automation.Q: When should manufacturers consider using a semi-automatic labelling machine instead of a fully automatic one?

A: Manufacturers should opt for a semi-automatic labelling machine when their production volume is moderate, or when flexibility and customization for diverse product types are required. This machine balances automation and manual control, making it cost-effective for smaller batches.Q: Where can the semi-automatic sticker labelling machine be effectively utilized?

A: This machine is suitable for various industries such as food and beverage, pharmaceuticals, cosmetics, and consumer goods. Its stainless steel construction and adaptable design make it compatible with multiple production environments, especially in India and export markets.Q: What is the process for labeling items using this machine?

A: The process involves placing the item on the machines platform, setting the label parameters via the computerized PLC panel, and initiating the labeling process. The machine then dispenses and applies self-adhesive stickers efficiently on each item.Q: How does electric drive contribute to the machines performance?

A: The electric drive delivers consistent power for smooth and efficient operation, permitting reliable label application. It reduces mechanical wear and provides easy start-stop functionality for operators.Q: What warranty and support are provided with this labelling machine?

A: The machine comes with a one-year warranty for parts and service, ensuring customer support from the manufacturer, supplier, exporter, and distributor based in India.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Automatic Packaging Machine Category

Bottle Cartoning Machine

Minimum Order Quantity : 1 Piece

Type : Pharmaceutical Packaging Machine

Warranty : 1 Year

Control System : Human Machine Interface

Material : SS

Computerized : No

PE Film Shrink Wrapping Machine

Minimum Order Quantity : 1 Piece

Type : Wrapping Machines

Warranty : 1 Year

Control System : PLC Control

Material : Stainless Stee

Computerized : Yes

Automatic Carton Opening Machine

Minimum Order Quantity : 1 Piece

Type : Sealing Machines

Warranty : 1 Year

Control System : PLC Control

Material : Stainless Steel

Computerized : Yes

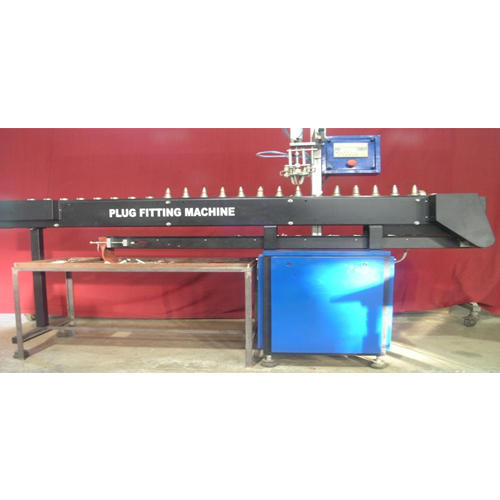

Plug Fitting Machine

Minimum Order Quantity : 1 Piece

Type : Capping Machines

Warranty : 1 year

Control System : PLC Control

Material : Stainless steel

Computerized : Yes

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free