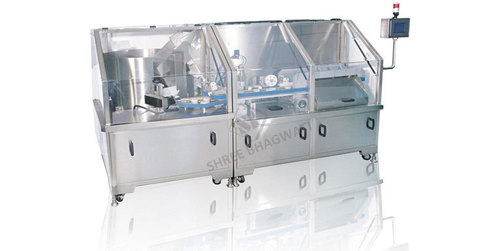

Automatic High Speed tablet /capsule Counting Machine

Automatic High Speed tablet /capsule Counting Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- India

- Supply Ability

- 30 Pieces Per Week

- Delivery Time

- 6-8 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box Packing Only

- Main Domestic Market

- All India

- Certifications

- ISO and CE Certified

About Automatic High Speed tablet /capsule Counting Machine

Technical parameters:-

|

Max Speed |

Up to 6000 Tablet or Capsules per Min. |

|

No. Of channels |

16 |

|

Filling Quantity per bottles |

15 to 10000 |

|

Hopper volume |

40 LTR |

|

Compressed Air |

0.5 Mpa |

|

Power Supply |

AC 220 V, 50 HZ |

|

Conveyor Length |

2400 mm |

|

Dimension |

1600 X 2400 X 1670 mm |

|

Net weight |

500 kg |

Optimized for Versatile Production Environments

The machines adjustable capacity allows businesses to tailor output according to their unique requirements, making it ideal for both large-scale and small-scale operations. Its automatic and computerized controls bolster accuracy while reducing manual labor, boosting overall productivity.

Stainless Steel Construction for Hygiene and Longevity

Crafted entirely from stainless steel, the machine underscores sanitation and robust performancekey components in pharmaceutical manufacturing. Its resistant material ensures a long service life, while the modern design enhances operational aesthetics.

Customizable Power and Dimensions

Engineered to fit seamlessly into various production spaces, this machine offers personalized power and voltage settings. Its dimensions (in inches) can be tailored as needed, ensuring compatibility with your facility layout and workflow.

FAQs of Automatic High Speed tablet /capsule Counting Machine:

Q: How does the Automatic High Speed Tablet/Capsule Counting Machine work?

A: This machine employs advanced sensors and computerized controls to accurately count and dispense tablets or capsules into bottles or designated containers. The automatic process minimizes human involvement, ensuring precise, rapid output.Q: What is the capacity of the machine, and can it be customized?

A: The capacity of the machine can be customized to align with client requirements. It measures output in kilograms per hour, allowing you to specify the throughput best suited for your operational needs.Q: When should I opt for an automated counting solution in my production facility?

A: Automated counting is ideal when you seek improved accuracy, increased speed, and reduced manual intervention in your packaging process, particularly for medium to high-volume production lines.Q: Where is the best place to install this machine in a manufacturing facility?

A: The machine is best placed within the packaging section of a production line, where counted capsules or tablets are immediately transferred for bottling. Its compact design (L*W*H in inches) ensures easy fit in existing layouts.Q: What is the process for operating the machine?

A: Operation involves loading tablets or capsules into the hopper, setting parameters via the computerized interface, and initiating the automatic counting cycle. The system manages the counting and dispensing process efficiently.Q: How is the machine maintained to ensure longevity?

A: Regular cleaning, routine inspection of moving parts, and timely software updates are recommended. The stainless steel construction facilitates easy cleaning and helps maintain hygiene standards essential in pharmaceutical production.Q: What are the benefits of using this automatic counting machine?

A: Users can expect enhanced counting accuracy, significant labor savings, improved output speed, and full compliance with industry hygiene standards due to the stainless steel construction. Additionally, customization ensures a perfect fit for your production requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Automatic Packaging Machine Category

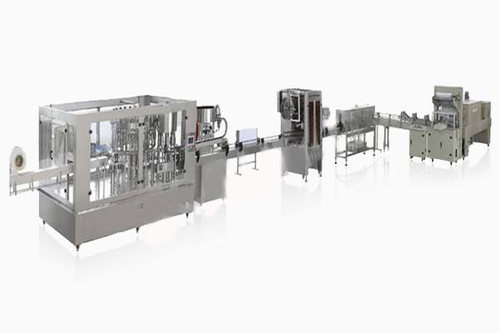

Automatic Filling Production Line For Mineral Water ,Pure Water

Minimum Order Quantity : 1 Piece

Color : Stainless Steel Finished

Computerized : Yes

Warranty : 1 Year

Material : Stainless Steel Alloy

Plastic Cup Package Industrial Yogurt Making Machine 6 Heads 4000 L/H

Minimum Order Quantity : 1 Piece

Color : Other

Computerized : Yes

Warranty : 1 year

Material : Stainless steel

Fully Automatic Shrink Sleeve Label Applicator Machine

Minimum Order Quantity : 1 Piece

Color : Silver

Computerized : No

Warranty : 1 Year

Material : SS

Automatic High Speed Unscrambler Machine

Minimum Order Quantity : 1 Piece

Color : stainless steel

Computerized : Yes

Warranty : 1 year

Material : Stainless steel

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS