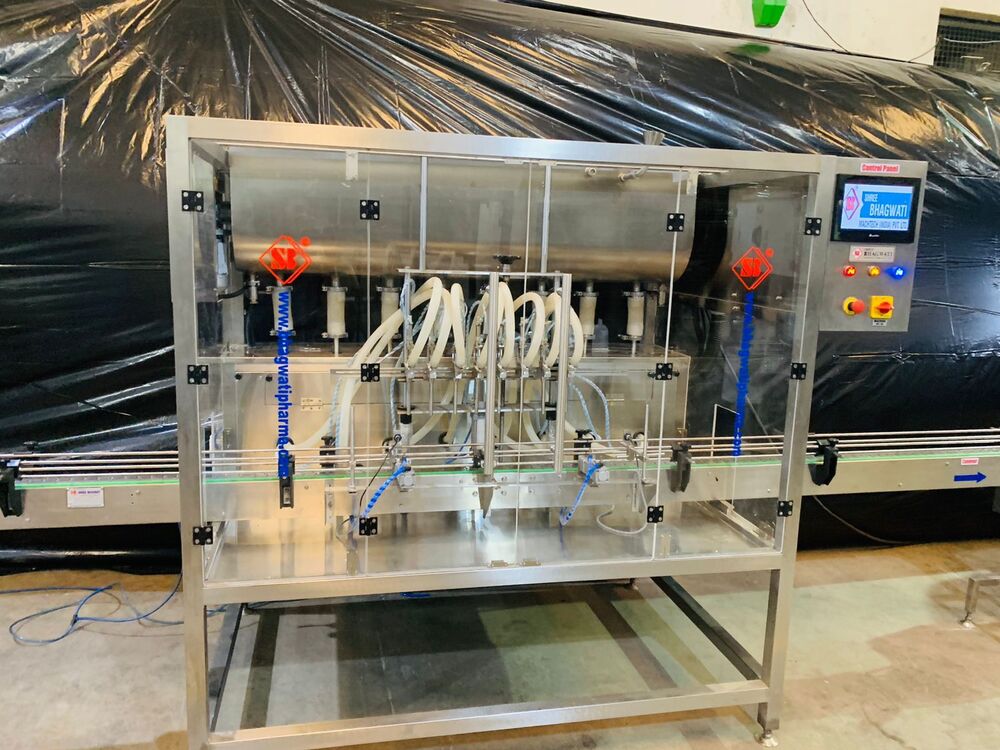

Chemical Filling Machine

Price 1600000 INR/ Unit

MOQ : 1 Unit

Chemical Filling Machine Specification

- Product Type

- Chemical Filling Machine

- Material

- SS

- Computerized

- No

- Automatic Grade

- Automatic

- Control System

- Human Machine Interface

- Drive Type

- Electric

- Feature

- ECO Friendly

- Warranty

- 1 Year

Chemical Filling Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 30 Units Per Month

- Delivery Time

- 8 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Packing Only

- Main Domestic Market

- All India

- Certifications

- CE & ISO Certified

About Chemical Filling Machine

Chemical Filling Machine

| |

| Fully Automatic Gear Pump Based filling machine Have following features: |

|

| Power Requirement: |

| 3 Phase, 440 Volts AC., 50 Hz. Air consumption: 1 to 2 CFM. Load : 6 Hp |

Exceptional Versatility and Reliability

Designed for flexibility, the Chemical Filling Machine accommodates a wide variety of container sizesfrom 50 ml to 5000 ml. Its stainless steel build safeguards against corrosion while maintaining optimal hygiene and durability. Whether you require basic Human Machine Interface control or sophisticated PLC automation, this machine effectively adapts to different operational needs.

Automatic and Eco-Friendly Operation

With its fully automatic grade and eco-friendly features, the Chemical Filling Machine streamlines the filling process while minimizing energy consumption and environmental impact. Electric drive ensures consistent performance, and the easy-to-use interface allows for quick setup, reducing downtime and increasing productivity in your production lines.

FAQs of Chemical Filling Machine:

Q: How does the Chemical Filling Machine ensure accurate filling for different container sizes?

A: The machine is engineered to dispense chemicals precisely from 50 ml to 5000 ml, using advanced control systems like Human Machine Interface or PLC. This flexibility allows it to handle various container sizes with consistent accuracy.Q: What materials are used in the construction of the Chemical Filling Machine?

A: The machine is made from high-grade stainless steel (SS), ensuring durability, corrosion resistance, and suitability for handling chemical substances in industrial environments.Q: When is the optimal time to perform maintenance on the Chemical Filling Machine?

A: Routine maintenance is recommended every few months, depending on your usage frequency. Regular checks and cleaning help sustain peak performance and prolong the lifespan, supported by the 1-year warranty.Q: Where can the Chemical Filling Machine be installed?

A: This machine is ideal for installation in industrial settings such as chemical manufacturing plants, laboratories, and processing units throughout India and other countries where distributors and exporters are active.Q: What is the process for adjusting the machine to fit specific voltage requirements?

A: The Chemical Filling Machine can be tailored to operate at any voltage specified by the customer during ordering. Simply inform your supplier of your voltage requirements for straightforward customization.Q: How does the automatic feature of the Chemical Filling Machine benefit users?

A: The automatic operation enhances productivity by reducing manual intervention, minimizing the risk of spillage, and ensuring uniform fillingall while being eco-friendly and energy-efficient.Q: What are the primary benefits of using this Chemical Filling Machine?

A: Key benefits include robust stainless steel construction, a wide filling capacity range, energy efficiency, low environmental impact, ease of use, and the assurance of a comprehensive 1-year warranty.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Liquid Filling Machine Category

Semi Automatic Two Head Viscous Filling machine

Price 350000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless steel

Computerized : No

Automatic Grade : SemiAutomatic

Warranty : 1 year

Liquid Soaps Filling Machine

Price 2000000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : SS

Computerized : No

Automatic Grade : Automatic

Warranty : 1 Year

Liquor Bottling Plant

Minimum Order Quantity : 1 Piece

Material : Stainless steel

Computerized : Yes

Automatic Grade : Automatic

Warranty : 1 Year warranty

Flowmatic 10 Head Cooking Oil Filling Machine

Price 2000000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : SS

Computerized : No

Automatic Grade : Automatic

Warranty : 1 Year

Let's talk business

Please take a moment to complete this form and a business representative will get back to you swiftly

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free