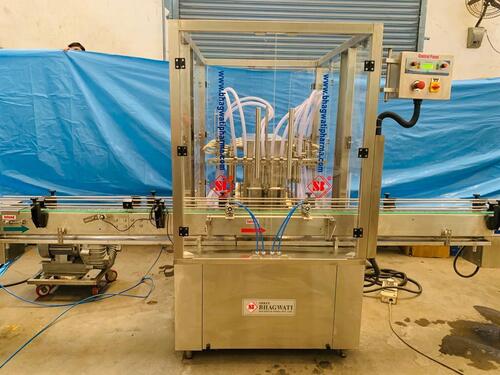

Volumetric Linear Bottle Filling Machine

Price 500000 INR/ Piece

MOQ : 1 Piece

Volumetric Linear Bottle Filling Machine Specification

- Material

- Steel

- Application

- Beverage

- Computerized

- No

- Automatic Grade

- Automatic

- Control System

- Human Machine Interface

- Drive Type

- Electric

- Voltage

- 220 Volt (v)

- Feature

- ECO Friendly

- Warranty

- 1 Year

Volumetric Linear Bottle Filling Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 30 Pieces Per Month

- Delivery Time

- 8 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Packing Only

- Main Domestic Market

- All India

- Certifications

- CE & ISO Certified

About Volumetric Linear Bottle Filling Machine

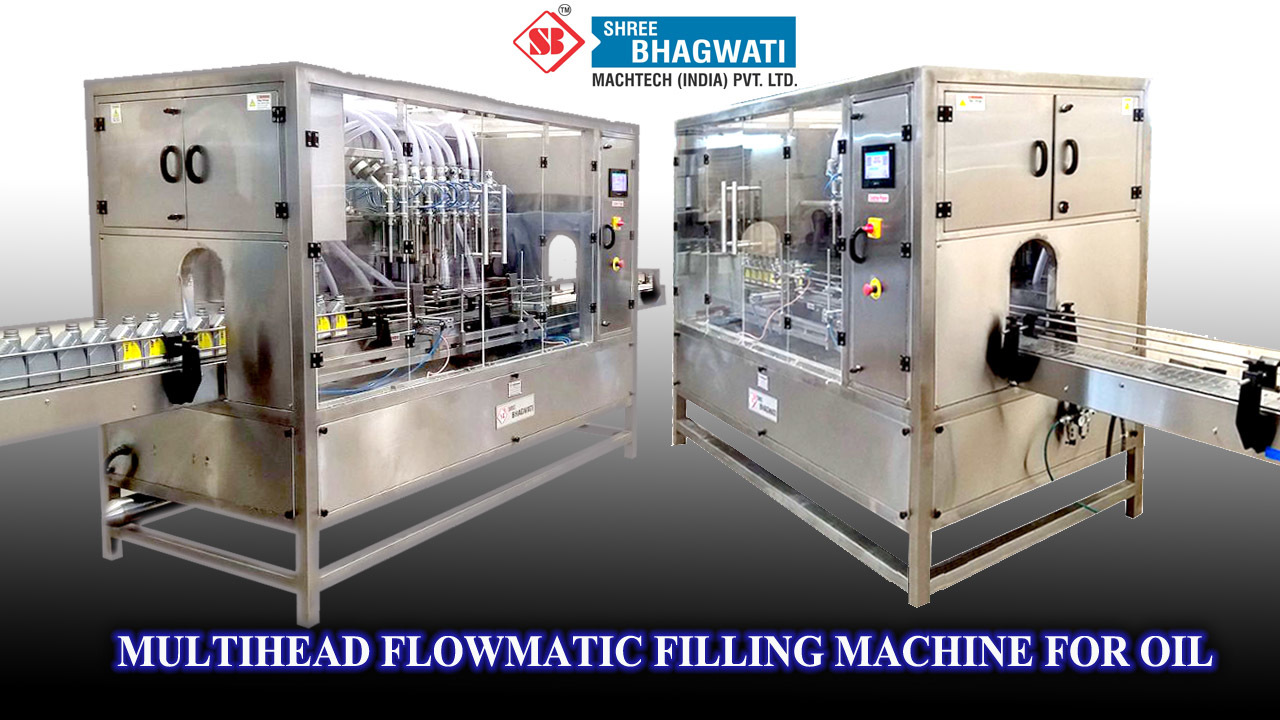

Volumetric Linear Bottle Filling Machine

|

|||

|

|

Advanced PLC-Controlled Automation

Enjoy streamlined operation with the integrated PLC control system, which automates bottle filling processes for enhanced accuracy and consistency. The computerized system simplifies adjustments, reduces manual intervention, and minimizes errors, making it ideal for high-production environments.

Flexible Filling Capacities and Durable Design

Accommodate a wide range of bottle sizes from 100ml to 1000ml thanks to adaptable machine settings. The stainless steel construction ensures longevity and corrosion resistance, supporting hygienic performance in demanding production settings.

FAQs of Volumetric Linear Bottle Filling Machine:

Q: How does the Volumetric Linear Bottle Filling Machine operate?

A: The machine functions through an electric drive and uses a PLC control system to manage the filling process automatically. Bottles are lined up, and liquid is dispensed into each bottle with volumetric precision, ensuring consistent fill levels and reducing product wastage.Q: What types of liquids can be filled using this machine?

A: This machine is suitable for a variety of liquid products, including water, juices, oils, chemicals, and pharmaceuticals, provided they have flow properties compatible with volumetric filling. Its stainless steel construction supports sanitary applications as well.Q: When should regular maintenance be performed on the machine?

A: It is recommended to conduct routine maintenance checks, such as cleaning, lubrication, and inspection of key components, at regular intervals based on usage frequency. Following the manufacturers maintenance schedule will help maintain optimal performance and extend the machines lifespan.Q: Where is this machine typically used?

A: The Volumetric Linear Bottle Filling Machine is widely used in industries such as food and beverage, cosmetics, pharmaceuticals, and chemical manufacturing. Its adaptability to various bottle sizes and liquid types makes it suitable for diverse production facilities.Q: What are the steps involved in the filling process?

A: The process involves aligning empty bottles on the conveyor, automatic filling of the required volume using computerized controls, and then capping and labeling. The entire workflow is managed through the machines PLC system for efficiency and accuracy.Q: What benefits does this machine offer to production facilities?

A: Key benefits include increased filling speed, precise volume control, reduced labor costs, and minimized product wastage. Its one-year warranty and tailored voltage options further add value for production operations in India and abroad.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Liquid Filling Machine Category

Honey Filling Machine

Price 1800000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : SS

Automatic Grade : Automatic

Drive Type : Electric

Computerized : No

Sauce Filling Machine

Price 1200000 INR / Unit

Minimum Order Quantity : 1 Piece

Material : SS

Automatic Grade : Automatic

Drive Type : Electric

Computerized : No

Automatic Rotary Piston Filling Machine

Price 1500000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : SS

Automatic Grade : Automatic

Drive Type : Electric

Computerized : No

Volummetric Six Head Liquid Filling Machine

Price 650000 INR / Unit

Minimum Order Quantity : 1 Piece

Material : SS

Automatic Grade : Automatic

Drive Type : Electric

Computerized : No

Let's talk business

Please take a moment to complete this form and a business representative will get back to you swiftly

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free