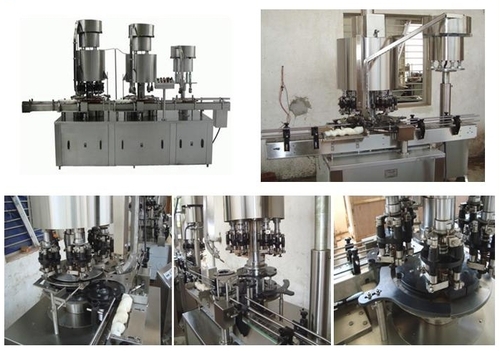

Automatic Single Head Crown Capping Machine

Automatic Single Head Crown Capping Machine Specification

- Type

- Capping Machines

- Material

- Stainless steel

- Auxiliary Packaging Machine Type

- Other

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Control

- Drive Type

- Electric

- Power

- As per the client required Watt (w)

- Voltage

- As per the client required Watt (w)

- Warranty

- 1 year

Automatic Single Head Crown Capping Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- India

- Supply Ability

- 30 Pieces Per Week

- Delivery Time

- 4-6 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Packing only

- Main Export Market(s)

- Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Asia

- Main Domestic Market

- All India

- Certifications

- ISO and CE certified

About Automatic Single Head Crown Capping Machine

Output

| Up to 20 BPM (Depending on bottle sizes) | |

| Electrical Motor | 1HP/230 Volts/ 3Phase/ 50 Hz (Four wire) For Main Machine |

| Conveyor Height | 750 mm to 840 mm Adjustable. |

| Container Size | 22 mm to 100 mm, Maximum Height 210 mm |

| Height of container | 50 mm to 210 mm Maximum, Option for other Bottle height available. |

Salient Features

- No Bottle,No crown system

- Complete Stainless Steel Covering

- Variable speed drive

- Adjustable Sealing pressure

- All Product contact parts are made up of Stainless Steel

- Single motor synchronizes conveyor, star wheels and sealing

Precision Capping with PLC Control

This machine utilizes a sophisticated PLC control system to automate the capping process, ensuring that every bottle is securely sealed with single-headed accuracy. The computerized workflow minimizes human error and streamlines operations for consistently high-quality results.

Customizable Power Options

The machine is available with adaptable voltage and power configurations tailored to meet each clients operational demands. This flexibility ensures compatibility with various facility standards while maintaining optimal performance and energy efficiency.

Robust Stainless Steel Construction

Manufactured using premium stainless steel, the capping machine offers superior corrosion resistance and structural durability. This prolongs its lifespan, making it an ideal investment for businesses seeking reliable bottling solutions in diverse industrial environments.

FAQs of Automatic Single Head Crown Capping Machine:

Q: How does the Automatic Single Head Crown Capping Machine operate?

A: The machine operates through an electric drive system, automatically positioning and capping bottles with a PLC-controlled mechanism. The computerized design monitors and regulates each step, ensuring consistent and secure closure of crown caps without manual intervention.Q: What are the main benefits of using this capping machine?

A: The primary benefits include increased operational efficiency, reduction in labor costs, consistent capping quality, easy integration into existing bottling lines, and robust stainless steel construction that resists wear and corrosion.Q: When is the machine best utilized in the production process?

A: This capping machine is best employed after the bottling and filling stage. It is intended to automate the capping process, saving time and improving productivity during high-volume production runs in beverage or other bottling industries.Q: Where can I install this capping machine?

A: You can install the machine in any industrial setting that requires automatic crown capping, such as beverage manufacturing plants, bottling units, and packaging facilities. Its design is adaptable to various line configurations due to customizable voltage and power options.Q: Can the machines power and voltage specifications be tailored according to client requirements?

A: Yes, the machine offers customizable voltage and power settings, allowing clients to specify their operational needs during purchase for optimal compatibility and performance in their facility.Q: What type of control system does the machine use?

A: The machine utilizes an advanced PLC control system, which manages and automates the capping process, providing precise control and easy programmability for different production requirements.Q: Is there a warranty provided for the Automatic Single Head Crown Capping Machine?

A: Yes, this machine is supplied with a one-year warranty, ensuring support and maintenance for optimal performance and peace of mind after installation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Capping Machine Category

Automatic Capping Machine

Price nan INR

Minimum Order Quantity : 1 Piece

Material : Stainless Steel

Drive Type : Electric

Warranty : 1 Year

Control System : PLC Control

Muti Head ROPP Capping machine

Price 1500000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : SS

Drive Type : Electric

Warranty : As per customer requirement

Control System : Human Machine Interface

Crown Capping Machine

Price 750000 INR / Unit

Minimum Order Quantity : 1 Piece

Material : SS

Drive Type : Electric

Warranty : 1 Year

Control System : Human Machine Interface

12 Head Aluminium vial Cap Sealing Machine

Price 1800000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : SS

Drive Type : Electric

Warranty : 1 Year

Control System : Human Machine Interface

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free