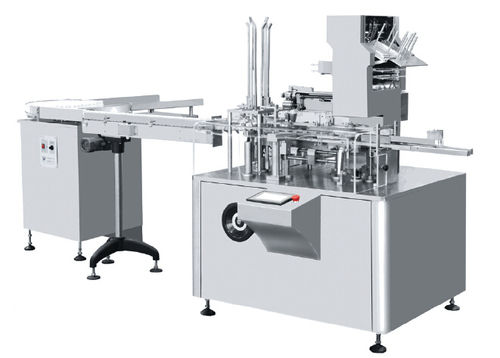

8 Head Air Jet Cleaning Machine with Turn Table

Price 1000000 INR/ Unit

8 Head Air Jet Cleaning Machine with Turn Table Specification

- Usage

- Industrial

- Power Supply

- Electric

- Material

- SS

- Computerized

- No

- Automatic Grade

- Automatic

- Control System

- Human Machine Interface

- Drive Type

- Electric

- Voltage

- 220-415 Volt (v)

- Color

- Silver

- Warranty

- 1 Year

8 Head Air Jet Cleaning Machine with Turn Table Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 5-10 Days

About 8 Head Air Jet Cleaning Machine with Turn Table

8 Head Air Jet Cleaning Machine with Turn Table

Shree Bhagwati Automatic Vertical Air-Jet Cleaning Machine work on positive air pressure & vacuum cleaning. The unit is made compact, versatile and enclosed in stainless steel elegantly matt finish body, consists of S.S. Slat Conveyor & Reciprocating cleaning nozzles. No container No cleaning system arrangement is standard features of the machine.

The main drive of the machine and conveyor drive consist of A/c Motor with synchronized variable A/c Frequency Drive.

Technical Details: :

Model No.SBVAJC-120

Out/PutUp to 100 Bottle per minute (Depend on neck size & bottle size)

GMP MODEL

Advanced Cleaning Efficiency

Equipped with eight powerful air jets and a rotating turn table, the machine thoroughly removes dust and particulates from bottles and containers, supporting hygienic operations in various industrial sectors. Its high-speed output streamlines production and improves cleanliness standards.

Automated Operation with HMI

The Human Machine Interface control system allows for easy configuration and monitoring of the cleaning process. Users can adjust parameters and control cleaning cycles efficiently without specialized computer systems. This minimizes training time and procedural complexity.

FAQs of 8 Head Air Jet Cleaning Machine with Turn Table:

Q: How does the 8 Head Air Jet Cleaning Machine with Turn Table operate in an industrial environment?

A: The machine functions by utilizing eight air jets that direct high-pressure air onto bottles or containers placed on its rotating turn table. This automatic action effectively removes dust, debris, and contaminants, preparing items for subsequent filling or packaging processes.Q: What materials is the machine constructed from and how does this benefit users?

A: The cleaning machine is built from stainless steel (SS), offering excellent resistance to corrosion and wear. This ensures long-term durability, easy maintenance, and consistent performance, especially in demanding industrial applications.Q: When is it recommended to use this air jet cleaning machine in production lines?

A: It is best utilized before the filling or packaging stages of industrial production, immediately after containers are supplied from storage. This timing maximizes product hygiene and safeguards against contamination.Q: Where can this machine be installed, and who supplies it in India?

A: The machine is suited for installation in industrial settings such as pharmaceutical, food, beverage, or chemical factories. It is distributed, exported, and manufactured by suppliers based in India, catering to both domestic and international markets.Q: What process does the turn table mechanism facilitate?

A: The turn table rotates containers systematically, ensuring that each bottle receives uniform air jet cleaning from all angles. This automated movement enables high throughput and consistent cleaning standards across large batches.Q: How is the machine controlled and does it require computerization?

A: It operates via a Human Machine Interface control system, allowing operators to manage settings and monitor the process intuitively. The machine does not require a computerized controller, simplifying operation and maintenance tasks.Q: What are the main benefits of using this automatic air jet cleaning machine?

A: Primary benefits include improved hygienic standards, increased cleaning speed, reduced manual labor, and enhanced product safety. The machines automatic operation also ensures reliable repeatability and minimizes operator intervention.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Automatic Packaging Machine Category

Automatic Cartooning Machine

Minimum Order Quantity : 1 Piece

Computerized : No

Voltage : 220415 Volt (v)

Power : As per the client required Watt (w)

Type : Pharmaceutical Packaging Machine

Automatic Tablet/ Capsule Filling Machine

Price 1100000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Computerized : Yes

Voltage : as per customer required Watt (w)

Power : as per customer required Watt (w)

Type : Tablet Counter

Automatic Capsule Filling Machine

Minimum Order Quantity : 1 Piece

Computerized : Yes

Voltage : As per the client required Volt (v)

Power : As per the client required Watt (w)

Type : Capsule Filing Machine

Online Injectable Vial Inspection Machine

Minimum Order Quantity : 1 Piece

Computerized : Yes

Voltage : As per the client required Watt (w)

Power : As per the client required Watt (w)

Type : Pharmaceutical Packaging Machine

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free