Wet Glue Labelling Machine

Price 750000 INR/ Unit

Wet Glue Labelling Machine Specification

- Product Type

- Wet Glue Labeling Machine

- Material

- SS

- Computerized

- No

- Automatic Grade

- Automatic

- Control System

- Human Machine Interface

- Drive Type

- Electric

- Feature

- ECO Friendly

- Warranty

- 1 year

Wet Glue Labelling Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 30 Pieces Per Month

- Delivery Time

- 6-8 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Packing Only

- Main Domestic Market

- All India

- Certifications

- CE & ISO Certified

About Wet Glue Labelling Machine

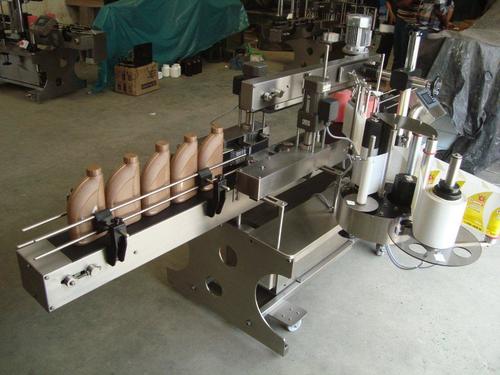

Wet Glue Labelling Machine

Self Adhesive Sticker Labelling Machine

Silent Features :

- Wet Glue Labelling Machine

- Self Adhesive Sticker Labelling Machine

- Suitable for Overlab Labelling & Flag Type Labelling

- NO CONTAINER - NO LABEL" - An Electrical Sensing Device avoids Wastage of Labels

- Special SELF-ALIGNING Bearings ensure Smooth and Life Time Trouble Free Rotation of the Parts

- An In-Built Mechanical Digital Counter provides continuous information of the Total Number

- Minimum change over time required from one size to another

Technical Specification

| Production Rate | 50 To 150 Round Bottles, Containers / Containers Per Minute |

| Power Specifications | 1.5 HP, 440 Volts, 3 Phase, 4 Wire System & 50 Hz |

| Net Weight | 580 Kgs. |

| Gross Weight | 1100 Kgs. |

| Overall Dimensions | 3000 mm (L) X 1061 mm (W) X 840 mm (H) |

Advanced Automation & Control

Equipped with a PLC control system and Human Machine Interface, this labelling machine simplifies operational management. Users benefit from intuitive controls that reduce human error and accelerate the labelling process, ensuring high output standards and consistent product quality in manufacturing environments.

Eco-Friendly Performance

Designed with eco-conscious principles, the Wet Glue Labelling Machine minimizes energy consumption and supports sustainable production practices. By combining automatic operation with efficient electric drives, it delivers performance while reducing the overall environmental footprint of your operations.

FAQs of Wet Glue Labelling Machine:

Q: How does the Wet Glue Labelling Machine operate with the PLC control system?

A: The machine utilizes a PLC (Programmable Logic Controller) and Human Machine Interface to manage all label application parameters. This setup enables users to efficiently control the process, adjust for different products, and monitor operation, ensuring precise and automatic labelling every time.Q: What is the maximum production capacity of this labelling machine?

A: The Wet Glue Labelling Machine can process between 30 to 300 tons per hour, making it suitable for both small-scale and large-scale manufacturing environments requiring high throughput and accuracy in labelling.Q: When should I schedule maintenance for the Wet Glue Labelling Machine?

A: Routine maintenance is recommended every six months or as detailed in the user manual. Regular checks help maintain optimal performance and prolong machine life, with a one-year warranty covering major components during the initial period.Q: Where is this labelling machine available for purchase in India?

A: You can obtain the Wet Glue Labelling Machine from authorized distributors, exporters, manufacturers, and suppliers throughout India. Contact local partners or reach out directly to the manufacturer for assistance and delivery options.Q: What are the benefits of using stainless steel in the construction of the labelling machine?

A: Stainless steel construction ensures durability, corrosion resistance, and hygiene, making the machine suitable for a variety of industrial labelling environments, including food, beverage, and pharmaceutical sectors.Q: How is the voltage specification determined for this machine?

A: The voltage requirement is customized according to your operational needs and location, ensuring safe and optimal performance. Customers can specify their preferred voltage during ordering and installation.Q: What makes this labelling machine eco-friendly?

A: Its electric drive system and automatic operation reduce energy consumption and operational waste. By optimizing resource use and supporting sustainable production, the Wet Glue Labelling Machine contributes to a greener manufacturing process.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sticker Labelling Machine Category

automatic front and back labeling machine

Price 750000 INR / Unit

Minimum Order Quantity : 1 Piece

Warranty : 1 year

Drive Type : Electric

Computerized : No

Automatic Grade : Automatic

Single Side Sticker Labeling Machine

Price 550000 INR / Unit

Minimum Order Quantity : 1 Piece

Warranty : 1 year

Drive Type : Electric

Computerized : No

Automatic Grade : Automatic

Vial Labelling Machine

Price 750000 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : 1 year

Drive Type : Electric

Computerized : No

Automatic Grade : Semi Automatic

Ampoule Labelling Machine

Price 750000 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : 1 year

Drive Type : Electric

Computerized : No

Automatic Grade : Automatic

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free