Wad inserting Machine Cap lining machine Single Double Head

Price 600000.00 INR/ Piece

Wad inserting Machine Cap lining machine Single Double Head Specification

- Usage

- Industrial

- Power Supply

- Electric

- Material

- SS

- Computerized

- No

- Automatic Grade

- Automatic

- Control System

- Human Machine Interface

- Drive Type

- Electric

- Color

- Silver

- Warranty

- 1 Year

Wad inserting Machine Cap lining machine Single Double Head Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 30 Pieces Per Month

- Delivery Time

- 6 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- wooden packing

- Main Domestic Market

- All India

- Certifications

- CE & ISO Certified

About Wad inserting Machine Cap lining machine Single Double Head

Wed inserting Machine, Cap lining machine:

Wed inserting Machine, Cap Wed inserting Machine The Automatic Wed inserting Machine is precision built on sturdy welded steel frame completely enclose in stainless steel sheet and doors are provided to facilitate the servicing of machine.

Operation:

The feed caps in vibrating bowl moving on chute are fed into star wheel, operating on Geneva mechanism. move on third part of induction where one pneumatic actuator put one wad into cap and at last part on induction wad will press by one mechanical operated rod.

Technical Specifications:

|

Model |

SBWI - 60 / 150 |

|

|

Output/Hour |

1000 to 9000. |

|

|

Direction of Movement |

Left to Right. |

|

|

Electrical Specification |

Main Motor |

2 HP max |

|

Cap Feeding Bowl |

20 MPR |

|

|

Working Height |

700 to 900mm |

|

|

Machine Dimensions Approx |

1250mm W x 1600mm L x 1500mm H |

|

|

Net Weight |

800kg |

|

|

Change parts required |

(A) Cap: Vibrating Bowl, Chute, Star Wheel. (B) Wad: Magazine, Pusher, Star wheel, Inserting Plate. |

|

Precision and Reliability in Cap Lining

This cap lining machine ensures consistent, high-quality wad insertion by employing precise electric-driven heads and advanced control systems. Whether your operation uses a single or double head, the robust stainless steel build and uniform electric supply safeguard long-term reliability for industrial applications.

Adaptable to Your Production Needs

With a capacity covering 1,000 to 9,000 mL and customizable voltage options, this machine seamlessly integrates into diverse production lines. The automated operation minimizes manual intervention, improving productivity and maintaining strict quality control across batches.

User-Oriented and Low Maintenance

Featuring Human Machine Interface (HMI) or PLC controls, operators enjoy intuitive start-up and process management. As an automatic, computerized solution (with select models), this equipment reduces training requirements and streamlines daily maintenance, backed by a comprehensive one-year warranty.

FAQs of Wad inserting Machine Cap lining machine Single Double Head:

Q: How does the Wad Inserting Machine Cap Lining Machine improve production efficiency?

A: The machine automates wad insertion and cap lining, minimizing manual labor and reducing the risk of errors. This accelerated process significantly boosts production speed and consistency across operations.Q: What is the process for setting up and operating the machine?

A: Installation involves connecting the unit to an appropriate electric supply and configuring initial settings via the Human Machine Interface or PLC control panel. Once set, operators load caps, and the machine automatically manages the wad insertion and lining sequence.Q: When should routine maintenance be performed on this machine?

A: Basic maintenance, such as cleaning and lubrication, should be performed daily or as recommended in the user manual. For optimal performance, a detailed inspection is advised every month or after extensive usage.Q: Where can this machine be used within the industrial sector?

A: The cap lining machine is ideal for manufacturers in the packaging, pharmaceutical, beverage, and chemical industries, and can be integrated into various industrial assembly lines requiring efficient and reliable cap lining.Q: What are the key benefits of using a stainless steel cap lining machine?

A: Stainless steel construction offers superior durability, resistance to corrosion, and hygiene compliancecritical for industries where cleanliness and longevity are paramount.Q: How can customers select the right voltage and control system for their operations?

A: Voltage and control options are selected based on your facilitys power specifications and process complexity. Customization ensures compatibility, and suppliers can assist in identifying the best configuration for your requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

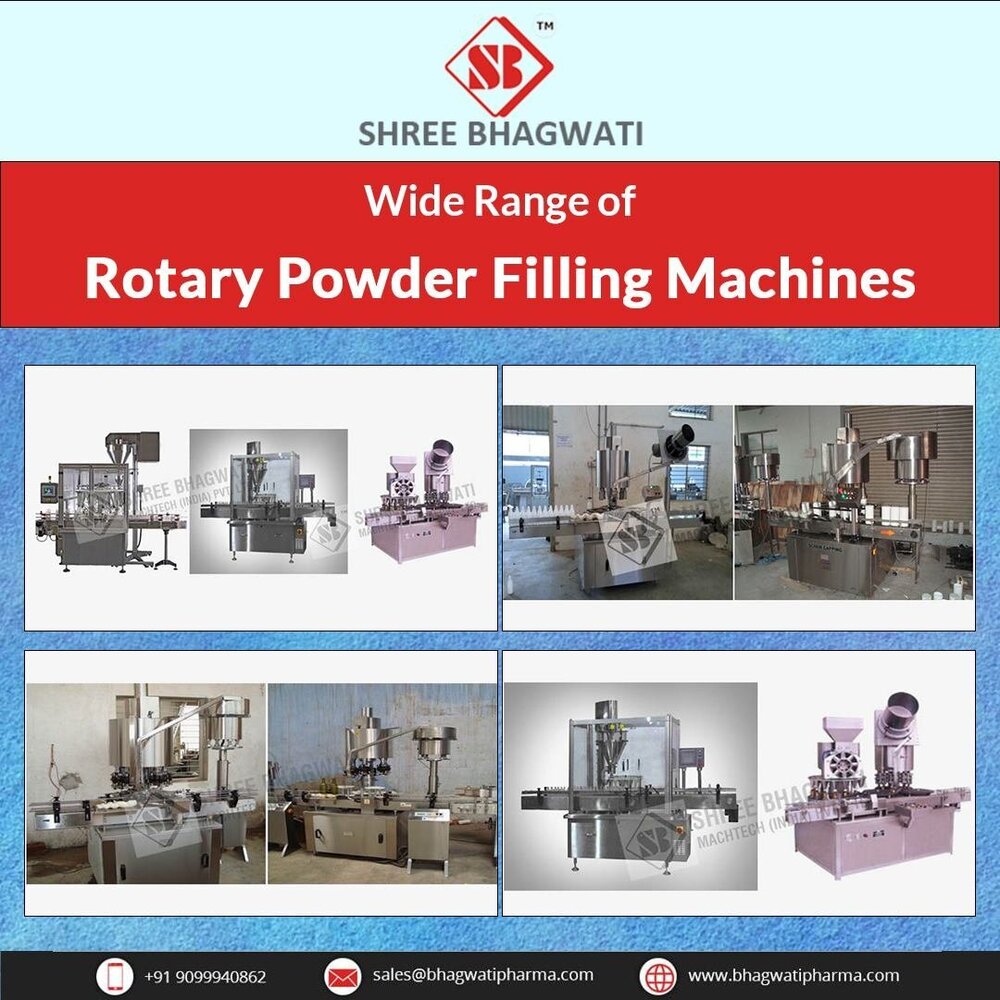

More Products in Automatic Powder Packing Machinery Category

Automatic 4 Head Vertical Air-Jet Cleaning Machine

Minimum Order Quantity : 1 Piece

Color : Silver

Material : SS

Usage : Industrial

Drive Type : Electric

Rotary Dry Syrup Powder Filling Machine

Price 2500000 INR

Minimum Order Quantity : 1 Unit

Color : Silver

Material : SS

Usage : Industrial

Drive Type : Electric

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free