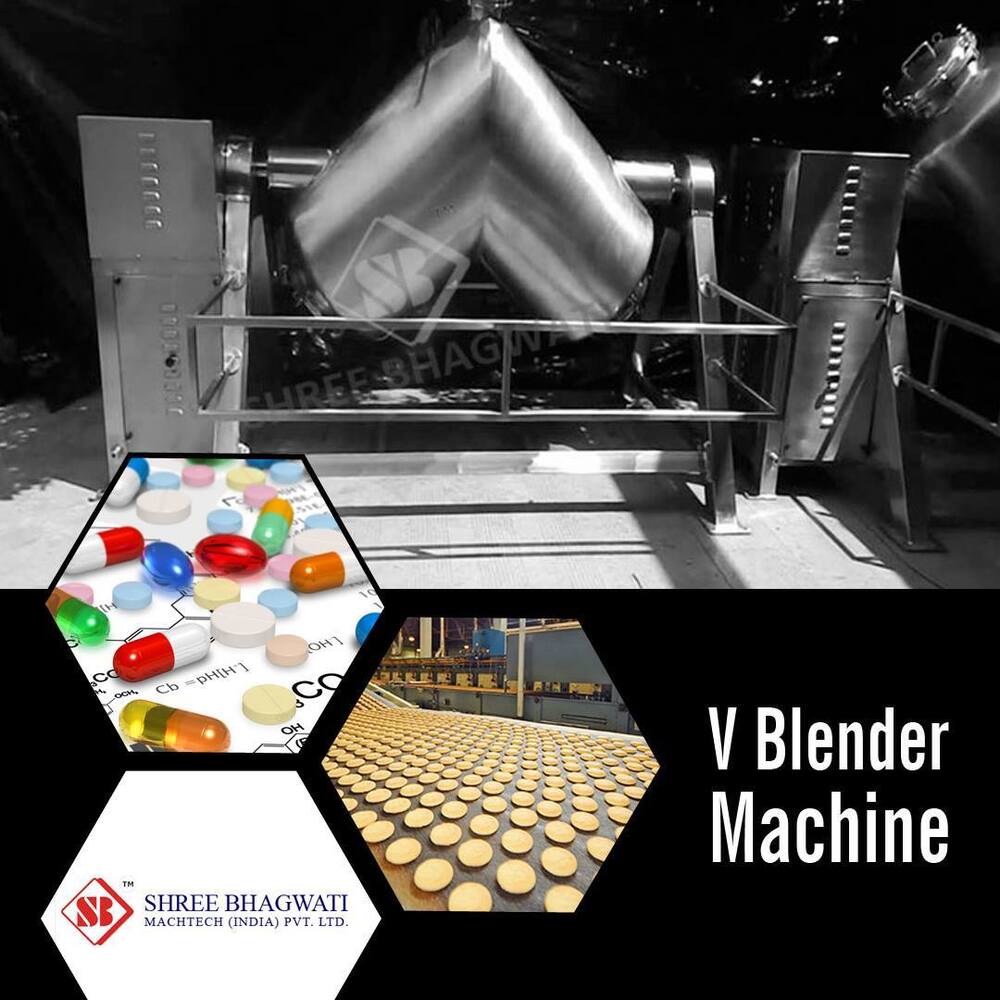

V Powder Mixer

V Powder Mixer Specification

- Type

- Powder Mixer

- Material

- SS

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Voltage

- 220-415 Volt (v)

- Warranty

- 1 Year

V Powder Mixer Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- India

- Supply Ability

- 30 Pieces Per Week

- Delivery Time

- 8-10 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Packing Only

- Main Domestic Market

- All India

- Certifications

- ISO and CE Certified

About V Powder Mixer

Description:-

Modifications such as the addition of baffles to increase mixing shear have been made to these types of blenders. Each cylindrical leg has an access cover for easy material loading and cleaning.

Special Features of V Cone Blender Machine:-

- Easy material loading and cleaning

- Short Blending Time.

- Large-Capacity equipment available

- Minimal maintenance

- Less power consumption

Superior Blending Efficiency

The V Powder Mixer stands out for its ability to uniformly mix a wide range of powder types. Its V-shaped chamber and semi-automatic operation make it especially suitable for achieving consistent results required in pharmaceutical production and other delicate applications.

Durable Stainless Steel Construction

Built from premium stainless steel, the mixer offers outstanding resistance to corrosion, ensuring longevity and hygienic operation. This construction makes it a preferred choice for industries with stringent cleanliness standards.

Customizable Capacity and Specifications

The mixer provides flexible capacity and power options, allowing adaptation to different production needs. Voltage specifications and dimensions can be tailored according to client requirements, catering to varied batch sizes and facility constraints.

FAQs of V Powder Mixer:

Q: How does the V Powder Mixer enhance the pharmaceutical packaging process?

A: The mixer streamlines the blending of powders by providing uniform mixing in a semi-automatic manner, improving product quality and ensuring consistent composition critical for pharmaceutical packaging.Q: What type of materials can be processed using the V Powder Mixer?

A: The V Powder Mixer is suitable for processing pharmaceutical powders, as well as materials in chemical and food industries, especially substances that require precise and homogeneous blending.Q: When should I consider customizing the mixers capacity or power?

A: Customization is recommended when your production volumes or powder characteristics necessitate specific size, power, or throughput. The manufacturer offers capacity and power options as per client requirements.Q: Where is the V Powder Mixer manufactured and supplied from?

A: The mixer is distributed, exported, and manufactured in India, ensuring quality control and reliable delivery for domestic and international clients.Q: What is the process for operating the mixer in automatic control mode?

A: Operation involves loading the powder into the chamber, selecting the mixing parameters, and starting the cycle via the control unit. The automatic control mode enables consistent, hands-free blending.Q: What are the benefits of choosing a stainless steel construction for the mixer?

A: Stainless steel ensures resistance to corrosion, maintains hygienic conditions, and supports the mixers longevity, making it ideal for applications with strict cleanliness and durability requirements.Q: Is computerized control available in all models of the V Powder Mixer?

A: Not all models are computerized. Some variants offer computerized control, while others are standard automatic. Clients can select the appropriate control mode based on their operational preferences.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Blenders Category

Drum Blender

Price 450000 INR / Unit

Minimum Order Quantity : 1 Piece

Voltage : 220415 Volt (v)

Material : Stainless Steel

Type : Pharmaceutical Packaging Machine

Computerized : Yes

Octagonal Blender

Minimum Order Quantity : 1 Piece

Voltage : As per customer requirement Watt (w)

Material : Stainless Steel

Type : Other

Computerized : Yes

Hopper Exchangeable Mixer

Minimum Order Quantity : 1 Piece

Voltage : As per the client required Volt (v)

Material : Stainless steel

Type : Pharmaceutical Packaging Machine

Computerized : Yes

Jacketed Plough Shear Mixer

Price 4000000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 220415 Volt (v)

Material : SS

Type : Plough Shear Mixer

Computerized : No

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS