Octagonal Blender

Octagonal Blender Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 30 Pieces Per Month

- Delivery Time

- 8 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Packing Only

- Main Domestic Market

- All India

- Certifications

- CE & ISO Certified

About Octagonal Blender

Octagonal Blender

The Octagonal Blenders work as an efficient as well as versatile blending productions employed for mixing as well as lubrication procedures of dry granules consistently. These render best results for grains due to extremely slow speed as well as octagon shapes of container. These are applicative for Food, Chemical, Pharmaceutical, and Cosmetic products. Suitable principally for Crystalline as well as Granular type material, these have adequate continuous motility due to their configuration. These high-quality Octagonal Blenders serve as the highly efficient as well as versatile blending machines for lubrication procedure.

Salient Feature

- The mechanism is designed by cGMP - Current Good Manufacturing Practices compliance

- All contact parts are completed by SS 316 & non contact parts are completed by SS 304.

- Octagonal shape container for perfect dry mixer for lubrication of granules and homogenization mixing of various batches in to solitary batch.

- Obtainable Capacity for octagonal blender 25 kg to 5000 kg batch size.

- Covered unbending drive with diminution mechanism box and motor.

- "A" type unbending composition of the machine with two sides inactive of product container.

- The container having exonerated with butterfly control device and man hole.

- Charging hole and hinged lid with shut for charging and cleaning.

- Safety reel provided for gyratory area of product container.

- Rigid baffles provided for lumps brake.

- Electric control panel with cycle time.

- Effortless design requires minimum maintenance.

- The octagonal shape & slow speed of gyratory gives enough constant progress to the granules, product in good feature.

- Bigger size consignment at low power expenditure.

Advanced Blending Technology

Engineered with stainless steel and automated PLC control, the Octagonal Blender delivers reliable and consistent mixing results. Its design minimizes wastage and ensures uniform blending, making it suitable for ingredients in pharmaceuticals, chemicals, and food processing industries.

Flexible Capacity for Multiple Needs

The adjustable capacity, ranging from 10 Kg/hr up to 10,000 Kg/hr, provides flexibility for both small batches and high-volume production. This makes it an ideal blending solution for businesses of various scales, accommodating customized operational requirements.

Comprehensive Support and Warranty

Each Octagonal Blender is backed by a 1-year warranty, ensuring peace of mind for customers. As a distributor, exporter, manufacturer, and supplier, we offer extensive support across India. Our customer-focused approach includes tailored voltage requirements and responsive service.

FAQs of Octagonal Blender:

Q: How does the Octagonal Blender operate and what controls are available?

A: The Octagonal Blender operates using an electric drive and features automatic, computerized control via a PLC system. This allows for easy, precise programming and monitoring of the entire blending process.Q: What materials are used in the construction of the Octagonal Blender?

A: The blender is constructed from high-quality stainless steel, ensuring durability, strength, and suitability for hygienic processing environments.Q: When should the Octagonal Blender be used in production?

A: This blender is ideal for use in mixing and blending dry powders or granules where uniformity is crucial, making it suitable for use at the batch blending stage in pharmaceuticals, food processing, and chemical manufacturing.Q: Where is the Octagonal Blender supplied and installed?

A: The Octagonal Blender is distributed, exported, manufactured, and supplied throughout India. Installation and support services are available nationwide.Q: What is the process for customizing the blenders power requirements?

A: Power requirements can be tailored according to customer specifications regarding voltage. During the order process, customers can provide their required wattage, and the unit will be manufactured accordingly.Q: How can using the Octagonal Blender benefit my business?

A: Utilizing this blender streamlines production through efficient automated blending, reduces manual labor, and ensures product consistency. Its robust construction also assures longevity and low maintenance costs.Q: What warranty and support are included with the Octagonal Blender?

A: Each unit comes with a 1-year warranty covering manufacturing defects, alongside comprehensive after-sales support and service provided by our team within India.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Blenders Category

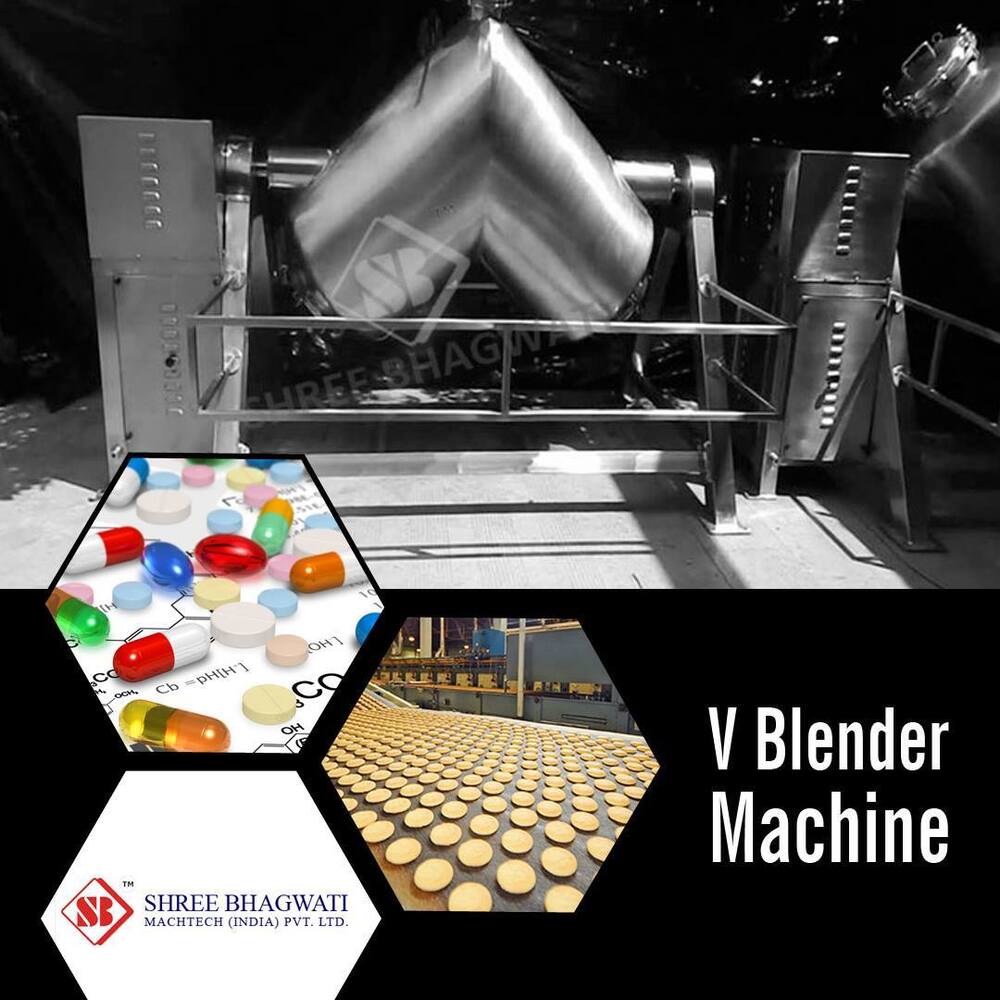

V Cone Blender

Price 250000 INR / Unit

Minimum Order Quantity : 1 Piece

Type : Pharmaceutical Packaging Machine

Material : SS

Automatic Grade : SemiAutomatic

Computerized : No

V Powder Mixer

Minimum Order Quantity : 1 Piece

Type : Powder Mixer

Material : SS

Automatic Grade : SemiAutomatic

Computerized : No

Plough Shear Mixer

Price 3000000 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Plough Shear Mixer

Material : SS

Automatic Grade : SemiAutomatic

Computerized : No

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free