V Cone Blender

Price 250000 INR/ Unit

V Cone Blender Specification

- Material

- SS

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Voltage

- 415 Volt (v)

- Frequency (MHz)

- 50 Hertz (HZ)

- Size

- Standard

- Warranty

- 1 Year

V Cone Blender Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- India

- Supply Ability

- 30 Pieces Per Week

- Delivery Time

- 10 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Packing Only

- Main Domestic Market

- All India

- Certifications

- ISO and CE Certified

About V Cone Blender

Description:-

Modifications such as the addition of baffles to increase mixing shear have been made to these types of blenders. Each cylindrical leg has an access cover for easy material loading and cleaning.

Special Features of V Cone Blender Machine:-

- Easy material loading and cleaning

- Short Blending Time.

- Large-Capacity equipment available

- Minimal maintenance

- Less power consumption

Efficient Blending for Pharmaceutical Needs

The V Cone Blender is engineered to provide uniform and thorough mixing, which is crucial in pharmaceutical applications where consistency is paramount. Its automatic and computerized controls allow for customizable operation cycles, ensuring optimal blending for various types of powders and granules.

Durable Construction and Reliable Performance

Constructed entirely from premium stainless steel, the V Cone Blender offers exceptional resistance to corrosion and wear. The one-year warranty further assures users of its long-term reliability and the manufacturers commitment to product quality.

FAQs of V Cone Blender:

Q: How does the V Cone Blender operate automatically?

A: The V Cone Blender utilizes a computerized control system, allowing users to program blending cycles, speeds, and durations for consistent, hands-free operation.Q: What materials can be processed in the V Cone Blender?

A: This machine is primarily designed for blending dry powders and granules, commonly used in the pharmaceutical, chemical, and food industries.Q: When should I consider using a V Cone Blender in pharmaceutical production?

A: You should use the V Cone Blender when uniform mixing and consistent batch quality are critical, such as in the formulation of tablets, capsules, or other pharmaceutical products.Q: Where is the V Cone Blender available for purchase?

A: The V Cone Blender is available through distributors, exporters, manufacturers, and suppliers across India, ensuring wide accessibility both domestically and for export.Q: What is the blending process in a V Cone Blender?

A: Materials are loaded into the V-shaped chamber, which rotates, allowing the powders or granules to cascade and tumble, resulting in a uniform blend without excessive shear.Q: How does using a stainless steel V Cone Blender benefit production?

A: Using stainless steel ensures high standards of hygiene, durability, and easy cleaning, making it especially beneficial for industries with strict quality requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Blenders Category

Drum Blender

Price 450000 INR / Unit

Minimum Order Quantity : 1 Piece

Computerized : Yes

Type : Pharmaceutical Packaging Machine

Warranty : 1 Year

Voltage : 220415 Volt (v)

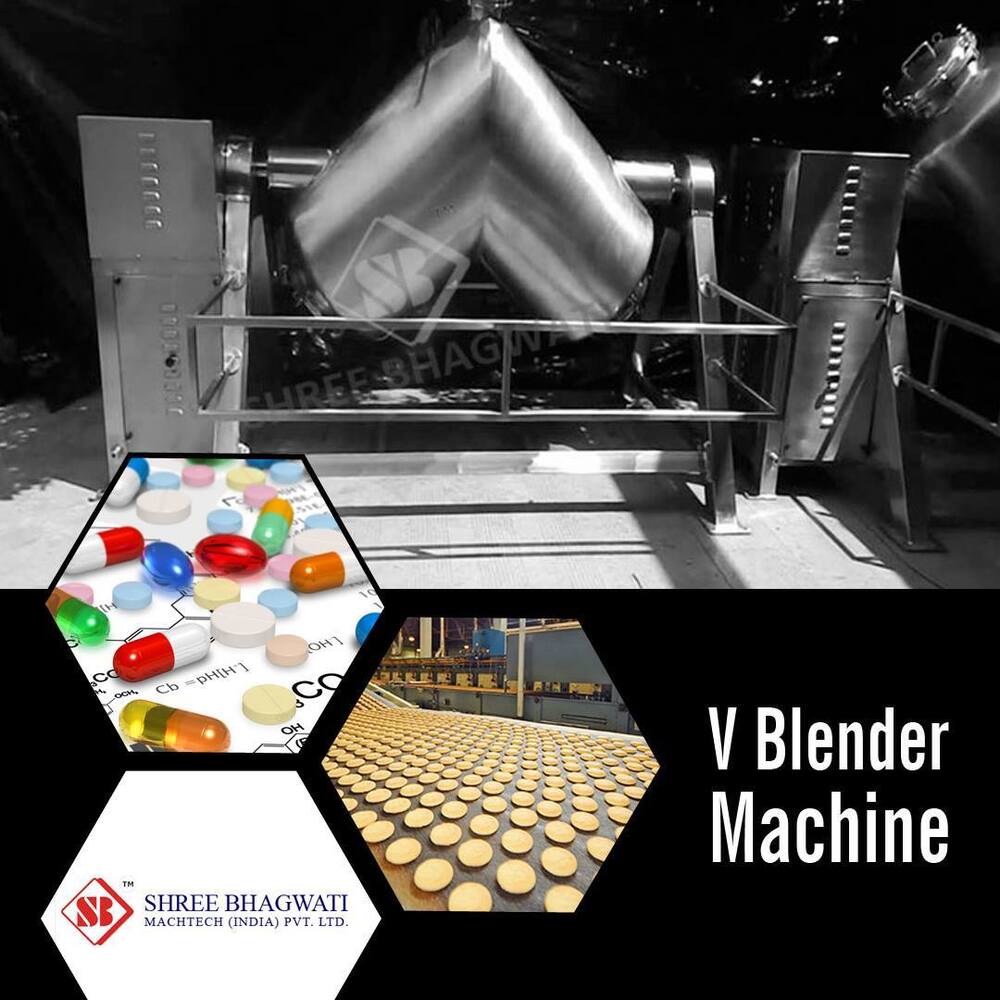

V Blender Machine

Minimum Order Quantity : 1 Piece

Computerized : Yes

Type : Pharmaceutical Packaging Machine

Warranty : stainless steel

Voltage : As per the client required Watt (w)

V Powder Mixer

Minimum Order Quantity : 1 Piece

Computerized : No

Type : Powder Mixer

Warranty : 1 Year

Voltage : 220415 Volt (v)

Jacketed Steam Heated Sigma Mixer

Price 6000000 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : No

Type : Sigma Mixer

Warranty : 1 Year

Voltage : 220415 Volt (v)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free