Tray Dryer

Tray Dryer Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 30 Pieces Per Month

- Delivery Time

- 10-12 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- wooden packing only

- Main Domestic Market

- All India

- Certifications

- CE & ISO Certified

About Tray Dryer

TechnicalSpecifications of Tray Dryer,

| Models | TD-12 | TD-24 | TD-48 | TD-96 | TD-192 |

| Loading capacity | 12 Trays | 24 Trays | 48 Trays | 96 Trays | 192 trays |

| External Dimensionin mm | W D H1370 X 530X 940 | W D H1370 X 940X 940 | W D H1980 X1020 X1880 | W D H3320X1900X1880 | W D H3320 X 1900X 1880 |

| Internal DimensionIn mm | 840 X 430 X 840 | 840 X 860 X 840 | 1020 X930 X1830 | 1960 X930 X1830 | 1960 X930 X1830 |

| No of Doors | One | One | One | Two | Two |

| No of Blowers | One | Two | One | Two | Four |

| No of motors / H.P.3 Phase 415 Volts. | 1 / 0.5 H.P.3 phase 415 volts. | 1 / 0.5 H.P.3 phase 415 volts | 1 / 1 H.P.3 phase 415 volts | 2 / 1 H.P.3 phase 415 volts | Four / 1 H.P.each3 phase 415 volts |

| ElectricalHeating Load for100C / 200C / 300C | 3kw / 6kw / 9kw | 6kw / 9kw / 12kw | 9kw / 15kw / 18kw | 15kw / 21kw / 27kw | 36kw / 42kw / 48kw |

| Steam HeaterNo. of coils. | 2 | 2 | 2 | 2 | 2 |

| Steam Pressure | 3.3 kg / cm2 | 3.3 kg / cm2 | 3.3 kg / cm2 | 3.3 kg / cm2 | 3.3 kg / cm2 |

| Steam consumption | 25 LBS / hr | 45 LBS/hr | 60 LBS / hr | 80 LBS / hr | 120 LBS / hr |

| Insulationin mm100C / 200C / 300C | 50 / 75 / 75 | 50 / 75 / 75 | 50/75/75 | 50 / 75 / 75 | 50 / 75 / 75 |

| No of Trolleys | Rack System | Rack System | One | Two | Four |

| Tray Size | 812 X 406 X 31 | 812 X 406 X 31 | 812 X 406 X 31 | 812 X 406 X 31 | 812 X 406 X 31 |

| Trolley Dimension | Fixed Racks | Fixed Racks | 840 X 960 X 1780 | 840 X 960 X 1780 | 840 X 960 X 1780 |

Salient Features

Construction: External : 2MM THK Internal : 2MM THKMOC:cGMP

Surface Finish : External:Buffed to 150 grit matt finishInternal: Buffed to 220 grit mirror finish.

Inlet & Outlet: Alldryers have a 5 micron pre filter r at the inlet and a manually infiniteadjustabledamper at the outlet.

Door : Doors at provided at the front and / or rearside of the dryer. Door lips are lined with silicon ruuber gasket to preventanyleakages. Suitable locking is provided for the doors.

Air Circulation : Air circulation is done by specially designedrecirculation blowers inside thedryer. The blower capacity , static &design depends on the size and model of dryer.

Heating : Dryers are normally supplied with eithersteam / electric / thermic fluid / hot water heating system. Suitable heatingcoils / caloriefiers are provided in the dryers.

Temperature Control : Temp control system is done by electronicdigital temp controller fitted in the control panel. The temp control in thedryer is fully automatic.

Trays : Trays are available in S.S. 304 / 316 q. Alltrays are fully die pressed and with cooved corners. Trays are buffed to mirrorfinish. Trays are also available in aluminium / Polypropelene / Frp / M.S.galvanized as per clients reqiuirements.

Trolley : Trolley is provided in the dryers toaccommodate trays in it. Trolley truck are used to load and unload the traysinto the dryer.

Control Panel : Automatic Control panel is fitted on the sideof the dryer. If consists of Starters, contactors, safety relays, ckt breakers,indicating lamps, push buttons , timers, controllers etc.

Advanced PLC and Touch Screen Controls

The tray dryer is equipped with a modern PLC control system and a user-friendly touch screen interface. This combination streamlines operation, maximizes efficiency, and offers precise control over drying parameters, ensuring consistent quality and reliability.

Eco-Friendly and Energy Efficient Design

Engineered for sustainability, the tray dryer features advanced technology that minimizes energy consumption while maintaining optimal performance. With low noise operation and eco-friendly materials, it supports green manufacturing processes and reduces operational costs.

Adaptable for Varied Industrial Needs

Whether you require drying capacity for small or large-scale production, the tray dryers versatile range from 6 to 240 trays can be tailored to your specific requirements. Its stainless steel construction and automatic features make it suitable for diverse industries across India.

FAQs of Tray Dryer:

Q: How does the PLC control system improve the tray dryers performance?

A: The PLC (Programmable Logic Controller) system automates the drying process, allowing for precise adjustment of temperature, timing, and airflow. This results in consistent drying quality, enhanced safety, and easier operation through the integrated touch screen interface.Q: What materials can be processed using this stainless steel tray dryer?

A: This tray dryer is suitable for drying a wide range of materials, including pharmaceuticals, food products, chemicals, and textiles. Its robust stainless steel construction ensures hygiene, durability, and resistance to corrosion.Q: When is it appropriate to use a high-capacity tray dryer?

A: A high-capacity tray dryer (up to 240 trays) is ideal when large volumes of material need to be dried efficiently, such as in large manufacturing plants or processing units that require fast turnaround times and consistent product quality.Q: Where can this tray dryer be installed and utilized?

A: The tray dryer can be installed in various industrial settings such as pharmaceutical manufacturing units, food processing plants, and chemical industries. Its electric power source and customizable voltage make it adaptable for installation across India or for export.Q: What is the process of operating the automatic tray dryer?

A: Operation involves loading the trays with material, setting the required parameters on the touch screen PLC control system, and initiating the drying cycle. The dryer automatically manages temperature, airflow, and timing for optimal results.Q: How does the tray dryer contribute to energy efficiency and eco-friendliness?

A: The dryer incorporates advanced insulation, efficient heating mechanisms, and smart control systems that reduce overall energy use. Additionally, low noise operation and eco-friendly materials further support sustainable industrial practices.Q: What benefits does the computerized design offer users?

A: The computerized design allows for easy monitoring, data recording, and precise process control. Operators can quickly adjust settings, trace performance trends, and achieve consistently high results with minimal manual intervention.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rotocone Vacuum and Tray Dryer Category

Hot Air Tray Dryer

Price 250000 INR / Unit

Minimum Order Quantity : 1 Piece

Material : Stainless Steel

Voltage : 110215 Volt (v)

Color : Silver

Usage : Industrial

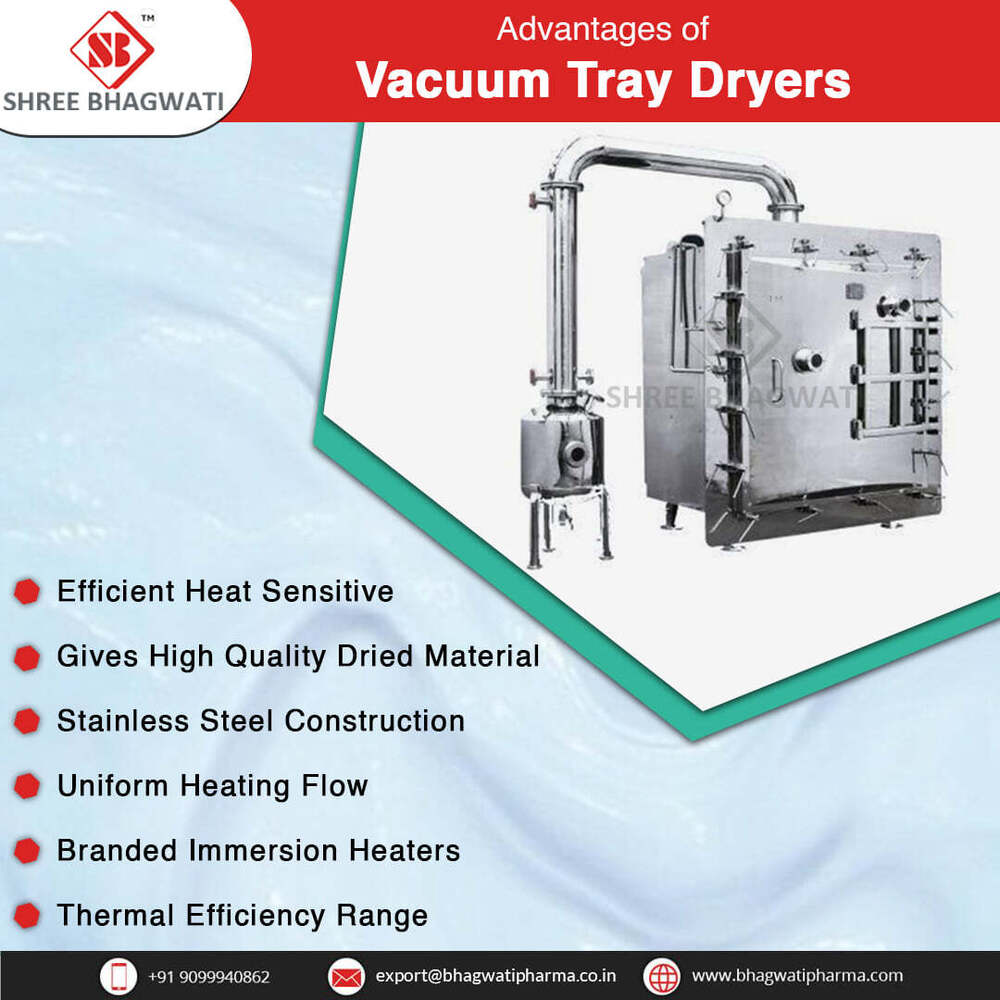

Vacuum Tray dryer

Price 500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Stainless Steel

Voltage : 220240 Volt (v)

Color : Silver

Usage : Industrial

Vacuum Tray Dryer - 12

Price 1500000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other, Stainless Steel 316 / 304

Voltage : 440 V

Rotocone Vacuum Dryer - Double Cone Vacuum Dryer

Price 2000000 INR / Unit

Minimum Order Quantity : 1 Unit

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free