Hot Air Tray Dryer

Price 250000 INR/ Unit

MOQ : 1 Piece

Hot Air Tray Dryer Specification

- Usage

- Industrial

- Material

- Stainless Steel

- Voltage

- 110-215 Volt (v)

- Product Type

- Hot Air Tray Dryer

- Color

- Silver

- Warranty

- 1 year

Hot Air Tray Dryer Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 30 Pieces Per Month

- Delivery Time

- 8 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Packing Only

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Middle East, Western Europe, Central America, Africa, Asia

- Main Domestic Market

- All India

- Certifications

- CE & ISO Certified

About Hot Air Tray Dryer

Hot Air Tray Dryer

Hot Air Tray Dryer Salient Features:

| | |||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||

Advanced PLC Control System

Our hot air tray dryer incorporates a PLC control system, allowing for precise temperature and process adjustments. This system enables automated operations, reduces manual intervention, and increases consistency in drying outcomes, making it ideal for industries requiring meticulous drying processes.

Versatile Tray Capacity

Available with a tray capacity ranging from 6 up to 240, this dryer accommodates both small batch and large-scale production. The flexible configuration helps manufacturers easily adapt to project demands, optimizing throughput without compromising drying efficiency.

FAQs of Hot Air Tray Dryer:

Q: How does the PLC control system enhance the operation of the hot air tray dryer?

A: The integrated PLC control system automates temperature regulation and timing, ensuring consistent drying cycles and reducing the need for manual monitoring, which improves accuracy and efficiency.Q: What is the benefit of using stainless steel in the construction of this dryer?

A: Stainless steel provides excellent durability, resistance to corrosion, and hygienic surfaces, making the dryer suitable for demanding industrial environments and applications involving food or chemicals.Q: When is the ideal time to use the hot air tray dryer in industrial processes?

A: The tray dryer is ideal for use during manufacturing stages that require thorough drying of materials, such as after washing or before packaging, ensuring moisture-free and commercially ready products.Q: Where can the hot air tray dryer be installed?

A: The dryer is designed for industrial settings and can be installed in factories, processing plants, or laboratories, as long as there is access to an appropriate electric power source and adequate ventilation.Q: What is the process involved in using the hot air tray dryer?

A: Material is loaded onto trays, which are placed into the chamber. Hot air circulates uniformly, removing moisture efficiently. The PLC system controls parameters, and the computerized interface allows monitoring and adjustments during operation.Q: What advantages does computerized control offer for drying operations?

A: Computerized control optimizes drying parameters, provides real-time monitoring, and facilitates data collection for process improvement, resulting in more consistent and high-quality output.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Rotocone Vacuum and Tray Dryer Category

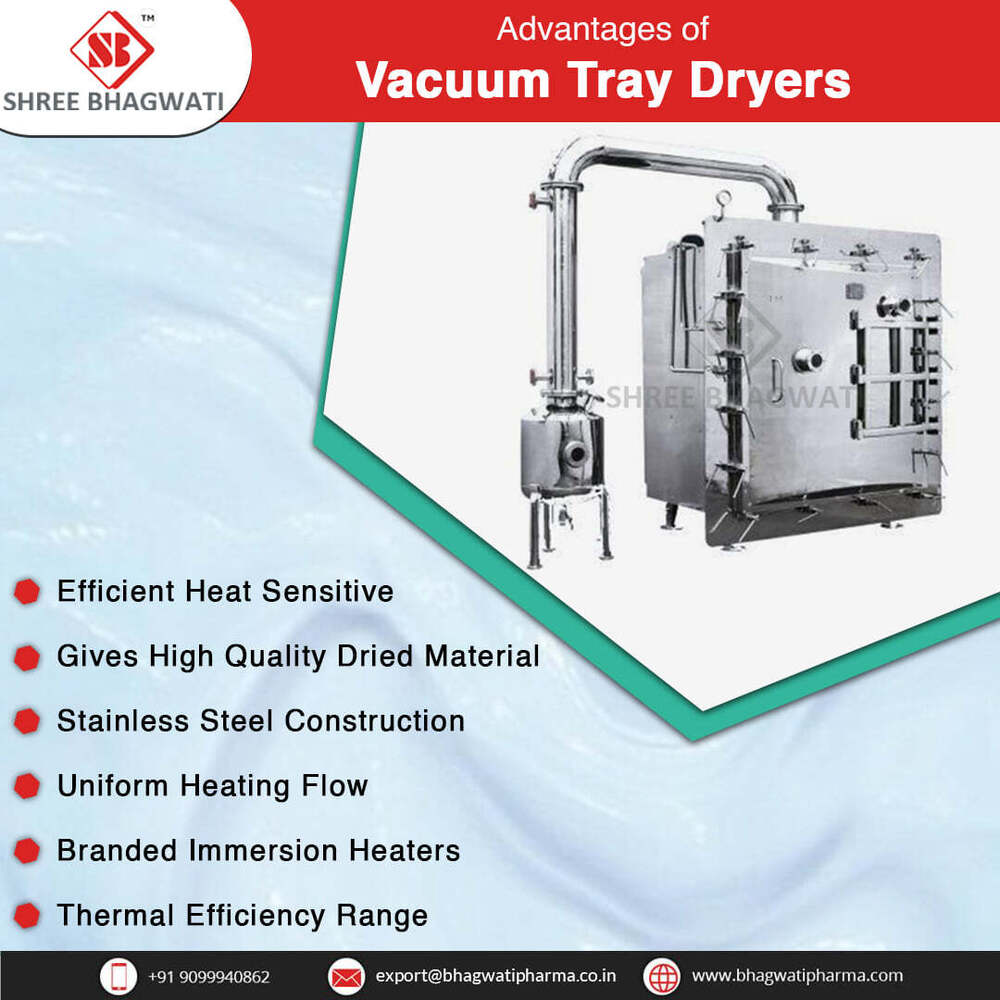

Vacuum Tray dryer

Price 500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : as per customer required Watt (w)

Material : stainless steal

Vacuum Tray Dryer - 12

Price 1500000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 440 V

Material : Other, Stainless Steel 316 / 304

Rotocone Vacuum Dryer - Double Cone Vacuum Dryer

Price 2000000 INR / Unit

Minimum Order Quantity : 1 Unit

Let's talk business

Please take a moment to complete this form and a business representative will get back to you swiftly

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free