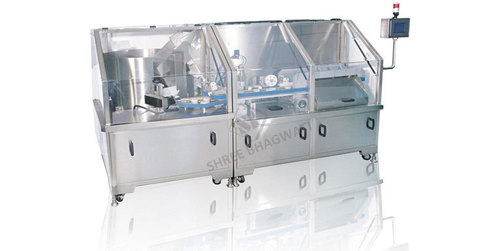

Shrink Sleeve Applicator

Price 1600000 INR/ Unit

MOQ : 1 Piece

Shrink Sleeve Applicator Specification

- Usage

- Industrial

- Features

- Good Quality

- Material

- SS

- Computerized

- No

- Automatic Grade

- Automatic

- Control System

- Human Machine Interface

- Drive Type

- Electric

- Voltage

- 220-415 Volt (v)

Shrink Sleeve Applicator Trade Information

- Minimum Order Quantity

- 1 Piece

- Delivery Time

- 10-15 Days

About Shrink Sleeve Applicator

Technical Specifications of Shrink Sleeve Labelling Machine

| Model | SB-SLEEVE-120 |

|---|---|

| Voltage | 220V/380V 50/60 HZ 3 PHASE |

| Bottle Diameter | 5595 / 95125 |

| Max. Speed | Up to 120 Bottle per minute |

| Power | 2.5KW |

| Label Insertion Length | 300MM |

| Range Of Label Thickness | 0.0350.08MM |

| Material | PVC/PET/OPS |

| Shrink Tunnel Capacity | 5KW17.5KW |

Efficient and Automated Operation

This Shrink Sleeve Applicator incorporates an electric drive system and HMI controls, enabling fully automatic operation. The intuitive interface simplifies configuration, reduces downtime, and enhances productivity in industrial settings. Built from high-quality stainless steel, it promises durability and consistent performance in demanding applications.

Versatile Industrial Compatibility

Engineered for use across a wide voltage range (220-415 Volt), the applicator adapts effortlessly to diverse industrial environments. Its robust structure ensures smooth integration into manufacturing and packaging lines, making it suitable for distributors, exporters, manufacturers, and suppliers in India pursuing reliable and scalable labeling solutions.

FAQs of Shrink Sleeve Applicator:

Q: How does the Shrink Sleeve Applicator operate with an electric drive and HMI control system?

A: The machine uses an electric drive for power and a Human Machine Interface (HMI) for control, allowing operators to easily monitor, configure, and manage the application process through a user-friendly interface.Q: What industrial benefits does the fully automatic grade provide?

A: Being fully automatic, the applicator increases labeling speed, minimizes manual intervention, and ensures accurate, consistent packaging, thus improving operational productivity and reducing labor costs.Q: When should a company opt for this shrink sleeve applicator over manual or semi-automatic models?

A: This model is ideal for high-volume, automated production lines where efficiency, quality, and integration with other automated equipment are critical requirements.Q: Where can this machine be implemented within the packaging process?

A: It is suitable for installation in industrial packaging units, particularly in sectors requiring consistent, high-speed application of shrink sleeves across a variety of products.Q: What is the standard process for applying shrink sleeves using this applicator?

A: Products are automatically fed into the machine, where the applicator precisely applies shrink sleeves. The sleeves are then shrunk onto the containers using heat, ensuring a secure and wrinkle-free fit.Q: How is the voltage range (220-415 Volt) advantageous in industrial settings?

A: The wide voltage compatibility enables seamless integration into different industrial facilities, accommodating various local electrical standards without requiring modifications.Q: What are the key benefits of using stainless steel (SS) as the material for this machine?

A: Stainless steel construction enhances the machines durability, resistance to corrosion, and ease of cleaning, making it ideal for rigorous industrial usage and compliance with hygiene standards.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Automatic Packaging Machine Category

Online Product Check Weigher

Price 850000 INR / Unit

Minimum Order Quantity : 1 Piece

Warranty : 1 year

Material : Stainless steel

Computerized : Yes

Type : Capping Machines

Automatic Tube Filling Sealing machine

Price 400000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Warranty : yes

Material : stainless steel

Computerized : Yes

Type : Pharmaceutical Packaging Machine

Automatic High Speed Unscrambler Machine

Minimum Order Quantity : 1 Piece

Warranty : 1 year

Material : Stainless steel

Computerized : Yes

Type : Other

Electronic Type Tablet Counting Filling Machine

Minimum Order Quantity : 1 Piece

Warranty : 1 Year

Material : SS

Computerized : No

Type : Tablet Counter

Let's talk business

Please take a moment to complete this form and a business representative will get back to you swiftly

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free