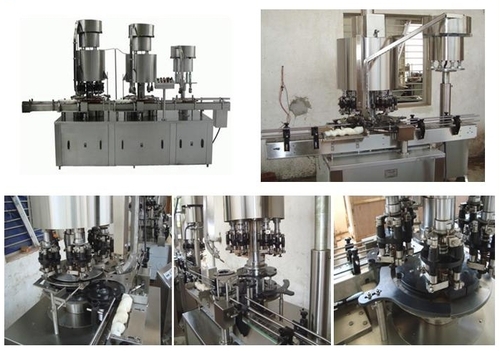

Semi Automatic Single head ROPP capping machine

Price 160000 INR/ Unit

Semi Automatic Single head ROPP capping machine Specification

- Type

- Sealing Machines

- Material

- Stainless Steal

- Auxiliary Packaging Machine Type

- Other

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Control System

- Human Machine Interface

- Drive Type

- Pneumatic

- Warranty

- 1

Semi Automatic Single head ROPP capping machine Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- India

- Supply Ability

- 30 Pieces Per Week

- Delivery Time

- 4-6 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Packing only

- Main Export Market(s)

- Western Europe, Australia, North America, Eastern Europe, Middle East, Central America, South America, Asia

- Main Domestic Market

- All India

- Certifications

- ISO and CE Certified

About Semi Automatic Single head ROPP capping machine

Operation

Require manually feeding& unloading container, where the body and the neck of the container arepositioned below the rotating head and sealing head is performing perfectoperation of capping with uniform torque.

Technical Specification

| Model | SBSC-40R |

| Output | Up to 08-10 BPM-Depending on operator speed |

| No. of sealing head | 1 Nos. |

| Electrical Motor | 1 HP / 440 Volts / 3 Phase / 50 Hz (Four wire) For Main Machine |

| Change parts required | Cap Die if cap diameter change. |

Precision Sealing for Bottled Packaging

This capping machine delivers consistent and secure sealing for bottles using ROPP caps. The pneumatic drive ensures high accuracy, making it ideal for pharmaceutical, cosmetic, and beverage sectors. The semi-automatic nature allows operators to efficiently manage the sealing process with minimal manual intervention, boosting productivity and ensuring compliance with industry standards.

User-Friendly Operation via Human Machine Interface

Operators benefit from an intuitive Human Machine Interface, which streamlines machine control and simplifies parameter adjustments. This enhances ease of use, minimizes training requirements, and reduces operational errors, making the machine accessible for users of various skill levels while sustaining maximum efficiency during production.

FAQs of Semi Automatic Single head ROPP capping machine:

Q: How does the Semi Automatic Single Head ROPP Capping Machine operate?

A: The machine utilizes a pneumatic drive system and is operated through a Human Machine Interface, enabling precise and semi-automatic placement and sealing of ROPP caps onto bottles with minimal operator intervention.Q: What materials are used in constructing the capping machine?

A: This machine is manufactured using premium stainless steel, which ensures durability, corrosion resistance, and compliance with sanitation requirements for bottling applications.Q: When is this capping machine typically used in the filling process?

A: The capping machine is employed after the bottles have been filled, serving as the final step to securely seal them, maintaining product integrity and preventing tampering or leakage.Q: Where can I source or purchase the Semi Automatic Single Head ROPP Capping Machine in India?

A: You can acquire this machine from authorized distributors, exporters, manufacturers, and suppliers located across India, who offer sales, installation, and service support.Q: What is the general process for using this sealing machine?

A: Bottles are loaded manually onto the machine. The operator selects control settings via the Human Machine Interface, after which the pneumatic system positions and seals each ROPP cap efficiently during each cycle.Q: What are the main benefits of using a semi-automatic ROPP capping machine?

A: Key advantages include improved sealing consistency, reduced manual labor, operator-friendly controls, robust stainless steel construction, and a one-year warranty for peace of mind.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Capping Machine Category

Flip Off Cap Sealing Machine

Price 350000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Silver

Warranty : 1 Year

Material : SS

Voltage : 220415 Volt (v)

Automatic Induction Cap Sealing Machine

Price 350000 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Warranty : 1 Year

Material : SS

Voltage : 220415 Volt (v)

Muti Head ROPP Capping machine

Price 1500000 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Warranty : As per customer requirement

Material : SS

Voltage : As per customer requirement Watt (w)

12 Head Aluminium vial Cap Sealing Machine

Price 1800000 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Warranty : 1 Year

Material : SS

Voltage : 110215 Volt (v)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free