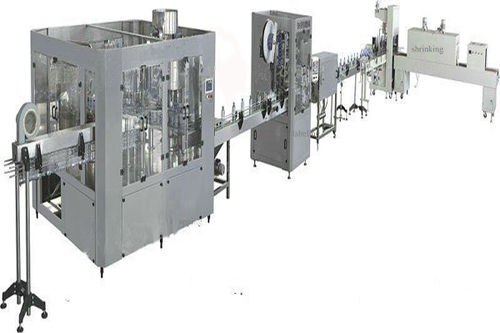

PE Film Shrink Wrapping Machine

PE Film Shrink Wrapping Machine Specification

- Type

- Wrapping Machines

- Material

- Stainless Stee

- Auxiliary Packaging Machine Type

- Other

- Capacity

- As per the client required Kg/hr

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Control

- Drive Type

- Electric

- Power

- As per the client required Watt (w)

- Voltage

- As per the client required Volt (v)

- Weight (kg)

- 1500 Kg Kilograms (kg)

- Dimension (L*W*H)

- L5500mm*W3200mm*H2100mm Millimeter (mm)

- Color

- Other

- Warranty

- 1 Year

PE Film Shrink Wrapping Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- India

- Payment Terms

- Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 1 Piece Per Week

- Delivery Time

- 4-6 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Packing only

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Central America, Africa, Asia

- Main Domestic Market

- All India

- Certifications

- ISO and CE Certified

About PE Film Shrink Wrapping Machine

Technical Specification:-

| Dimension for the whole unit: | L5500mm*W3200mm*H2100mm |

| Thermal shrinkage passage dimension: | L1800mm*W650mm*H450mm |

| Maximum package dimension: | L600mm*W400mm*H350mm |

| Packaging speed: | 7PCS/min |

| Transfer belt dimension: | 550mm |

| Sealing and cut time/temperature: | 0.5-1.5s 140oC-160oC |

| Operating power supply/power: | 380V 17kw |

| Packing format: | 2*3, 3*4, 3*5, 4*5, 4*6 |

| Applicable bottle: | Round or square |

| Packing material: | PE film |

| Thickness of film: | 0.06--0.12mm |

| Operating air pressure: | 0.6-0.8Mpa |

| Air consumption: | 0.5m3/minute |

| Total Weight: | 1500KG |

Advanced PLC Control System

The machines intelligent PLC control system streamlines packaging operations, allowing precise adjustments and monitoring. Operators can efficiently manage settings through its user-friendly computerized interface, optimizing productivity and minimizing errors. This technology ensures consistent wrapping quality across various batch sizes.

Customizable for Diverse Applications

With power, voltage, and production capacity tailored to client specifications, the PE Film Shrink Wrapping Machine fits seamlessly into different production lines. Its robust stainless steel construction and sizable frame accommodate high-volume operations, making it suitable for manufacturers, exporters, and distributors alike.

Automated Efficiency and Durability

Designed for automatic operation, the machine significantly reduces manual labor and enhances speed. The electric drive and heavy-duty build support continuous, reliable use while the stainless steel exterior guarantees longevity and resistance to wear. A one-year warranty underlines the manufacturers commitment to quality and customer satisfaction.

FAQs of PE Film Shrink Wrapping Machine:

Q: How does the PLC control system enhance the machines operation?

A: The PLC control system automates and regulates the wrapping process, offering precise control over parameters such as speed, temperature, and film tension. This results in reduced human intervention, improved consistency, and efficient troubleshooting.Q: What types of products can be shrink wrapped using this machine?

A: This wrapping machine is versatile and can accommodate a range of products, including boxes, bottles, cans, and other goods that benefit from protective PE film packaging. Its adjustable settings cater to various dimensions and weights as per client requirements.Q: When should I consider using this shrink wrapping machine in my production line?

A: This machine is ideal when you require high-speed, consistent, and protective packaging for products needing secure transportation or storage. It is especially beneficial for businesses scaling up production or aiming for higher packaging standards.Q: Where is this PE Film Shrink Wrapping Machine manufactured and supported?

A: The machine is manufactured, distributed, exported, and supported in India, ensuring easy access to after-sales service, spare parts, and technical assistance for Indian and global clients.Q: What is the process of shrink wrapping with this machine?

A: Products are automatically fed onto the conveyor, wrapped in heat-shrinkable PE film, and passed through a heated tunnel. The film shrinks tightly around the items, providing a secure and professional finish.Q: How user-friendly is the computerized interface for operators?

A: The machine features a modern computerized interface designed for ease of use. Operators can quickly learn to set parameters, monitor production, and manage maintenance through intuitive touch controls and clear displays.Q: What are the main benefits of using this wrapping machine for my business?

A: Key benefits include increased packaging speed, reduced labor costs, enhanced product protection, consistent packaging quality, and the flexibility to adapt to various product sizes. The automatic operation further boosts productivity and workplace safety.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Automatic Packaging Machine Category

Online Bottle Neck Trimming Machine

Minimum Order Quantity : 1 Piece

Computerized : Yes

Drive Type : Electric

Warranty : 1 year

Automatic Grade : Automatic

Automatic Carton Opening Machine

Minimum Order Quantity : 1 Piece

Computerized : Yes

Drive Type : Electric

Warranty : 1 Year

Automatic Grade : Automatic

Automatic Juice Production Line

Minimum Order Quantity : 1 Piece

Computerized : Yes

Drive Type : Electric

Warranty : 1 Year

Automatic Grade : Automatic

Semi Automatic Shrink Wrapping machine

Price 650000 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : No

Drive Type : Electric

Warranty : 1 year

Automatic Grade : SemiAutomatic

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free