Ointment Plant with Inline Homogenizer

Price 2000000 INR/ Unit

Ointment Plant with Inline Homogenizer Specification

- Type

- Pharmaceutical Packaging Machine

- Material

- Stainless steel

- Capacity

- As per the Client required Kg/hr

- Computerized

- Yes

- Control Mode

- Automatic

- Voltage

- As per the client required Watt (w)

- Power

- As per the client required Watt (w)

- Weight (kg)

- In kgs Kilograms (kg)

- Dimension (L*W*H)

- In inches Inch (in)

- Color

- stainless steel

- Warranty

- 1 year

Ointment Plant with Inline Homogenizer Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- India

- Supply Ability

- 30 Units Per Week

- Delivery Time

- 12-14 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Packing Only

- Main Domestic Market

- All India

- Certifications

- ISO and CE Certified

About Ointment Plant with Inline Homogenizer

Ointment Plant mainly consists of followingequipment's:-

- Manufacturing Vessel - Along with Baffles & Jacket

- Main Agitator Anchor type with Teflon scrapers

- Hydraulic Lifting Arrangement

- Inline Homogenizer

- Wax & Water Phase Vessel Baffles Jacket

- Agitator Propeller Type

- Storage Tank

Working Platform - Dimpled Sheet

Pipelines - Water Phase & Wax phase vessels are connected to the Main manufacturing vessel through individual pipelines. Inline conical filters are provided after each vessel bottom outlet.

Finished products are pumped out from the manufacturing vessel, through a third line by a lobe pump, into the storage tank. This line also has an inlineconical filter. The storage tank bottom outlet is connected to a metering pump.All connections like bends, tees, valves, inline sight glasses are ofTriclover/Din Standards.

Finished products are pumped outfrom the manufacturing vessel, through a third line by a lobe pump, into thestorage tank. This line also has an inline conical filter. The storage tankbottom outlet is connected to a metering pump. All connections like bends,tees, valves, inline sight glasses are of Triclover/Din Standards.

Advanced Inline Homogenization

The integrated inline homogenizer in the ointment plant delivers superior mixing for smooth and consistent ointment textures. This technology minimizes product variability, ensuring quality control in every batch. The result is a homogeneous blend that meets stringent pharmaceutical standards.

Automatic Computerized Operation

With fully automatic and computerized controls, operational complexity is dramatically reduced. The user-friendly interface streamlines production, lowers human error risk, and enhances overall workflow efficiencysupporting high-volume operations and scaling with your business needs.

Customized Design & Capacity

Built to suit specific client requirements, the machine accommodates various power, voltage, dimensions, and capacity options. This tailored approach ensures optimal integration into any production facility, maximizing productivity and space utilization without compromise.

FAQs of Ointment Plant with Inline Homogenizer:

Q: How does the inline homogenizer improve the ointment manufacturing process?

A: The inline homogenizer ensures a uniform dispersion of ingredients throughout the ointment, resulting in a consistent, high-quality product. It efficiently reduces particle size and eliminates lumps, meeting pharmaceutical standards for texture and stability.Q: What is the benefit of having an automatic, computerized control mode?

A: With automatic computerized controls, the machine offers precise process management, minimizes manual intervention, enhances safety, and maintains consistent quality across batches. This greatly streamlines production and reduces operator workload.Q: When should the Ointment Plant be serviced during its warranty period?

A: It is recommended to follow routine maintenance schedules outlined in the manual. On noticing any abnormal operation, you can reach out to your supplier or manufacturer within the 1-year warranty period for service or technical support to ensure optimal performance.Q: Where can this ointment plant be installed?

A: This machine can be installed in pharmaceutical manufacturing units, research labs, or industrial facilities across India. Its customizable size and features allow integration into diverse operational environments.Q: What is the process for customizing the capacity, power, and dimensions of the machine?

A: Customization is managed according to client specifications during the ordering process. Clients can discuss requirements with the distributor, exporter, manufacturer, or supplier to ensure the machine matches their unique production needs.Q: How is the stainless steel construction beneficial for pharmaceutical packaging?

A: Stainless steel is non-corrosive, hygienic, and easy to clean, making it the preferred material for pharmaceutical equipment. Its robust structure extends machine life and complies with GMP standards for safe drug production.Q: What usage advantages does this plant bring to pharmaceutical manufacturers?

A: Manufacturers benefit from reliable automated operation, precise ingredient blending, flexibility in machine configuration, and strong after-sales support, facilitating efficient high-volume ointment production.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

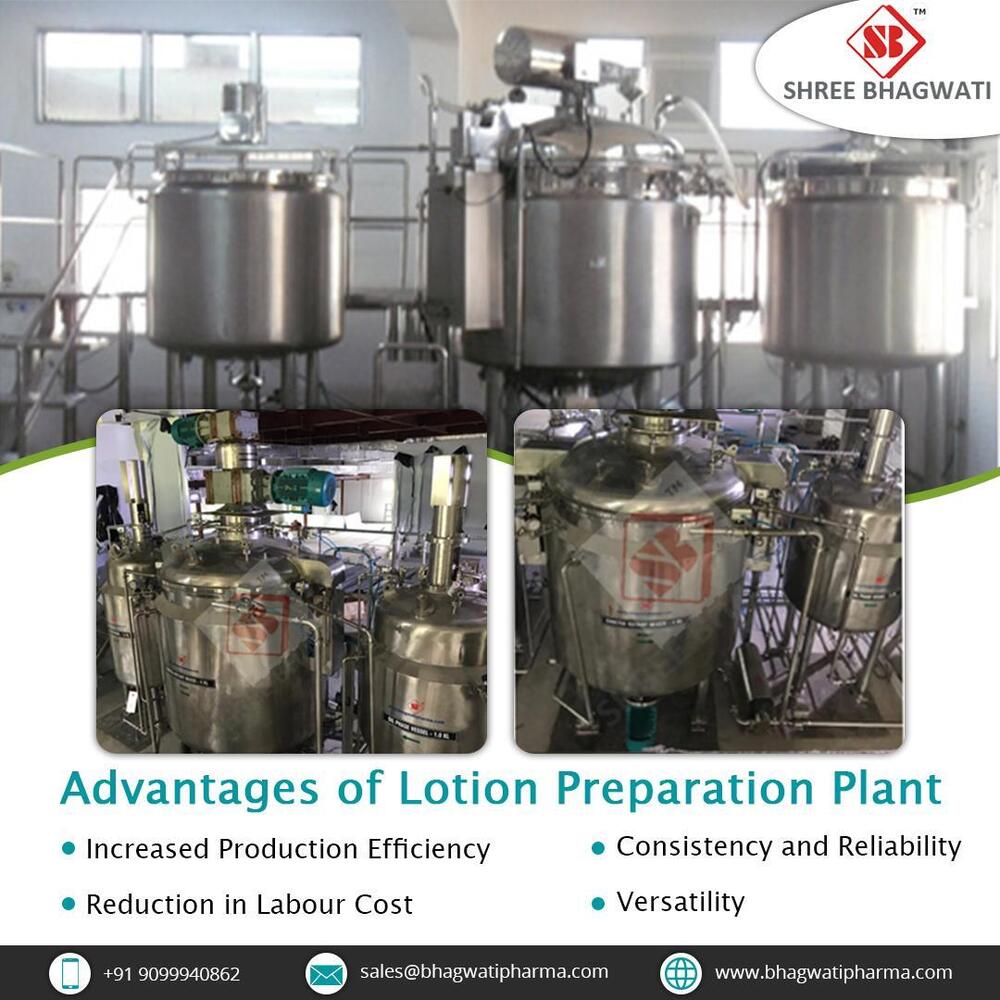

More Products in Lotion Manufacturing Plant Category

Lotion Manufacturing Plant

Minimum Order Quantity : 1 Piece

Computerized : Yes

Capacity : As per the Client required Kg/hr

Dimension (L*W*H) : In inches Inch (in)

Voltage : As per the client required Volt (v)

Weight (kg) : In kgs Kilograms (kg)

SS storage vessels

Minimum Order Quantity : 1 Piece

Computerized : Yes

Capacity : As per the Client required Kg/hr

Dimension (L*W*H) : In inches Inch (in)

Voltage : As per the client required Watt (w)

Weight (kg) : In kgs Kilograms (kg)

Lotion Manufacturing Machine

Minimum Order Quantity : 1 Piece

Computerized : Yes

Capacity : As per the Client required Kg/hr

Dimension (L*W*H) : In inches Inch (in)

Voltage : As per the client required Volt (v)

Weight (kg) : In kgs Kilograms (kg)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free