Lotion Manufacturing Plant

Lotion Manufacturing Plant Specification

- Type

- Pharmaceutical Packaging Machine

- Material

- Stainless steel

- Capacity

- As per the Client required Kg/hr

- Computerized

- Yes

- Control Mode

- Automatic

- Voltage

- As per the client required Volt (v)

- Power

- As per the client required Watt (w)

- Weight (kg)

- In kgs Kilograms (kg)

- Dimension (L*W*H)

- In inches Inch (in)

- Color

- stainless steel

- Warranty

- 1 year

Lotion Manufacturing Plant Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- India

- Supply Ability

- 30 Pieces Per Week

- Delivery Time

- 4-6 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box Packing Only

- Main Domestic Market

- All India

- Certifications

- ISO and CE Certified

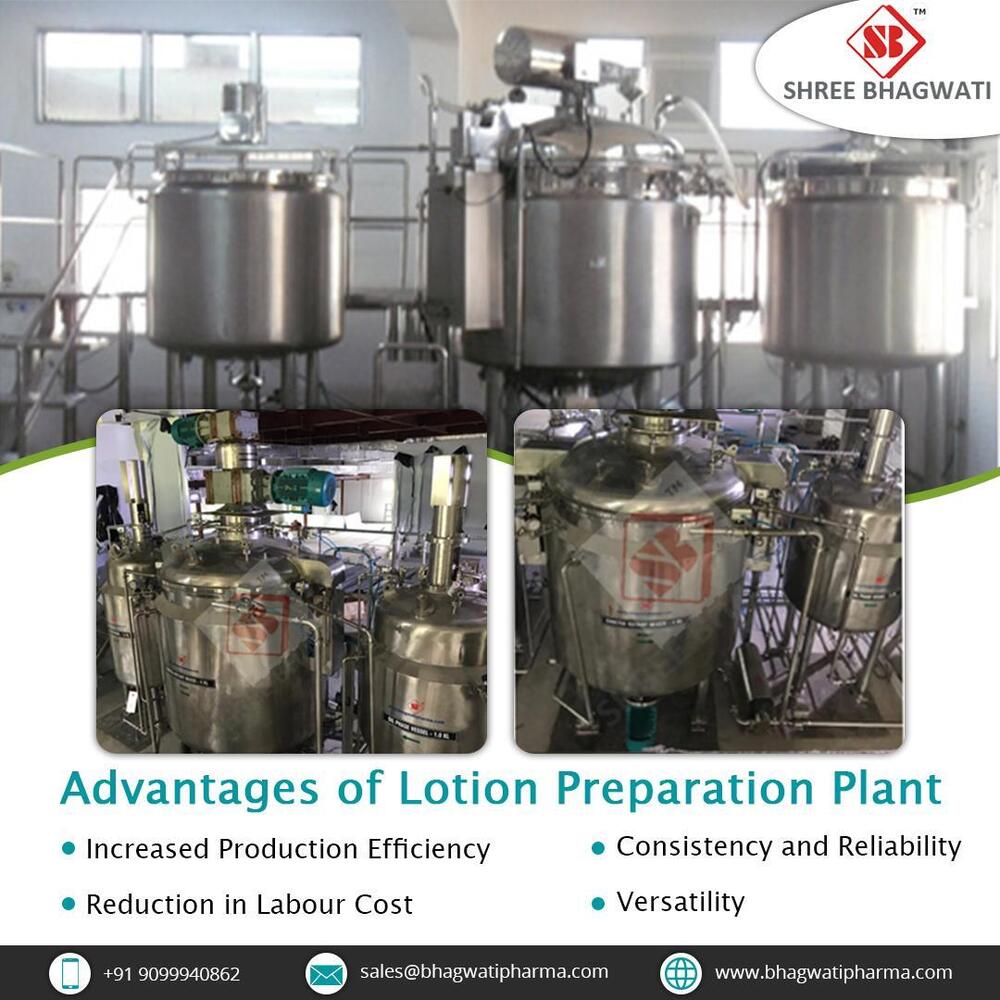

About Lotion Manufacturing Plant

Description:-

Shree Bhagwati is offering Below is a partial few lists of our Cream / Gel manufacturing plant, ointment manufacturing machine, Cream/Gels/Balm & Face Pack manufacturing equipment& manufacturing formulas for skin care, Hair Care products that we can manufacture for you on request.

Shree Bhagwati group is manufacturing and offering word class manufacturing plant and, Jar, Tube and bottle filling,capping, induction sealer, labeler and shrink sleeve applicator, shrink packing machine and carton box packing machines with wide range production output 3000 bottle per day to 200000 bottles per day.

Standard Features:-

- Capacity range from100-30000L

- Mild Steel /Stainless Steel construction

- One end welded and one end bolted

- Normal Temperature and Pressure inside mixer

- Gear Reducer Motor

- Gland Packing Seal+ Air Purge Seal

- Pneumatic Operated Outlet Valve

Customizable Design for Diverse Needs

The lotion manufacturing plant is designed to match every clients specifications for power, voltage, and capacity, making it versatile for varying operational scales. Whether you require a modest setup or a large-scale production facility, this equipment aligns with your business goals and technical preferences.

Advanced Automation and Computerized Control

With an automatic control mode and computerized interface, this plant optimizes both output quality and operator safety. It streamlines operational tasks, reduces error margins, and allows for precise programming, ensuring efficient, high-quality lotion production.

Superior Build Quality and Warranty Assurance

Crafted entirely from stainless steel, this lotion manufacturing plant delivers unmatched durability and hygiene. Enjoy peace of mind with a comprehensive 1-year warranty and the robust performance this plant provides, making it suitable for Indias demanding pharmaceutical sector.

FAQs of Lotion Manufacturing Plant:

Q: How is the capacity of the Lotion Manufacturing Plant determined for my business?

A: The capacity of the plant is completely customizable and set according to your specific production needs, measured in kilograms per hour. Consult with our technical team to specify the throughput that aligns with your operational requirements.Q: What steps are involved in the installation and setup process?

A: Once your requirements for power, voltage, and size are finalized, our technicians will assist with on-site installation and provide comprehensive guidance on setting up the automatic controls and computerized systems for optimal performance.Q: When can I expect delivery and commissioning of the plant in India?

A: Delivery timelines depend on customization details and location, but we strive for prompt dispatch and installation across India. For specific schedules, please contact our sales team with your order details.Q: Where can this lotion manufacturing plant be deployed?

A: The plant is suitable for pharmaceutical packaging units, cosmetics manufacturers, and third-party production facilities across India. Its adaptable dimensions allow flexibility in diverse industrial environments.Q: What are the main benefits of a computerized and automatic control mode?

A: Computerized and automatic controls ensure precise manufacturing, minimize human error, and offer streamlined data tracking for quality assurance. This results in consistent, high-quality output and reduced operational downtime.Q: How does the stainless steel construction benefit my production process?

A: Stainless steel material provides superior corrosion resistance, easier cleaning, and high durability, all vital for maintaining hygiene and complying with pharmaceutical standards.Q: What kind of warranty support is available for this plant?

A: The plant comes with a comprehensive 1-year warranty covering manufacturing defects and component failures, giving you dependable after-sales support and technical assistance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Lotion Manufacturing Plant Category

Ointment Plant with Inline Homogenizer

Price 2000000 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : Yes

Type : Pharmaceutical Packaging Machine

Warranty : 1 year

Power : As per the client required Watt (w)

Lotion Manufacturing Machine

Minimum Order Quantity : 1 Piece

Computerized : Yes

Type : Pharmaceutical Packaging Machine

Warranty : 1 year

Power : As per the client required Watt (w)

SS storage vessels

Minimum Order Quantity : 1 Piece

Computerized : Yes

Type : Pharmaceutical Packaging Machine

Warranty : 1 year

Power : As per the client required Watt (w)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS