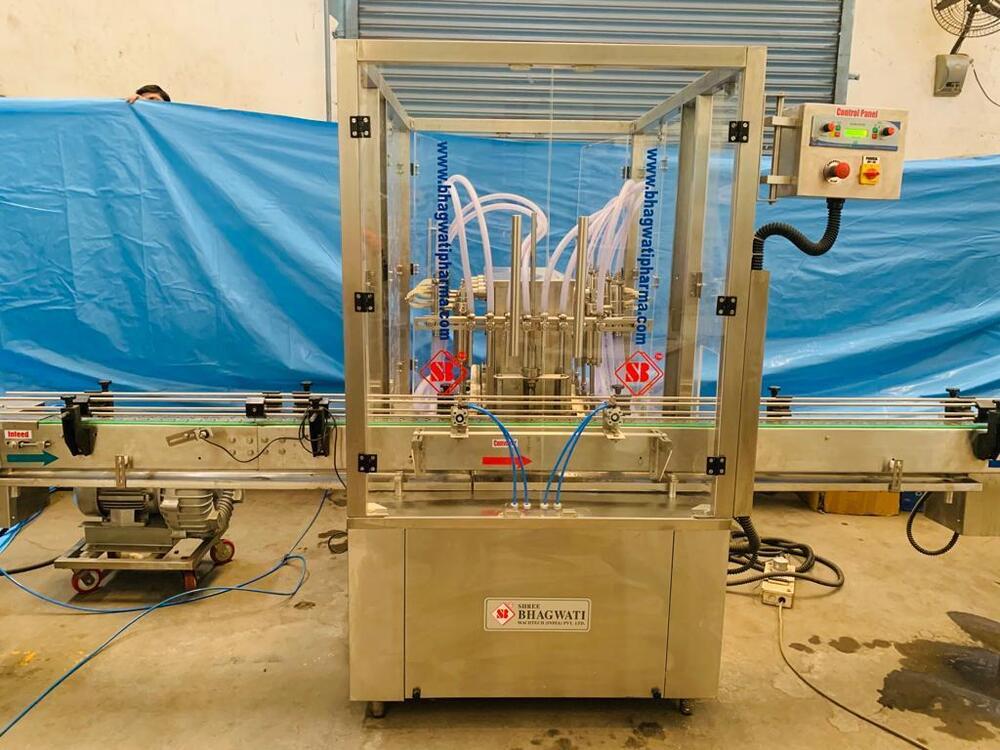

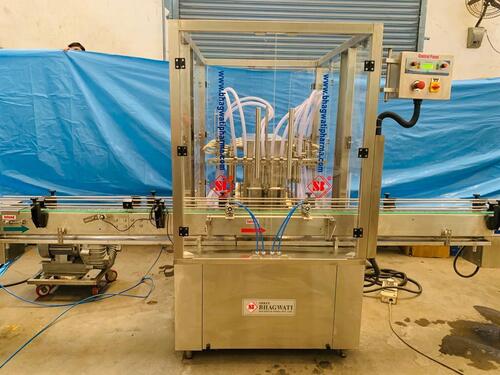

Milk Filling Machine

Price 1000000 INR/ Unit

MOQ : 1 Unit

Milk Filling Machine Specification

- Product Type

- Milk Filling Machine

- Material

- SS

- Computerized

- No

- Automatic Grade

- Automatic

- Control System

- Human Machine Interface

- Drive Type

- Electric

- Feature

- ECO Friendly

- Warranty

- 1 Year

Milk Filling Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 30 Units Per Month

- Delivery Time

- 8-10 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Packing Only

- Main Export Market(s)

- Australia, South America, Eastern Europe, Middle East, Western Europe, Central America, Asia, North America, Africa

- Main Domestic Market

- All India

- Certifications

- CE & ISO Certified

About Milk Filling Machine

Milk Filling Machine

- Liquid Filling machine can produce 50-200 bottles per minute by adding multiple heads to filler head Vinegar filling, perfume filling are used in liquid filling machine .

- Motor driven machine.

- SS304/316 contact Parts.

- Clean cut-off & dripp free filling with special nozzle designs.

- Foam free filling with diving nozzles for foaming products.

Advanced Automation for Streamlined Milk Filling

This Milk Filling Machine integrates cutting-edge automatic control, allowing consistent and high-speed filling operations. With a simple Human Machine Interface or PLC control system, operators can set desired parameters to match precise packaging requiements. Its reliability and user-friendly controls help minimize downtime and maximize production.

Versatile Capacity and Custom Voltage Solutions

Adaptable to different production demands, the machine can efficiently handle milk volumes from 100 mL to 2000 mL. Voltage can be tailored as per customer requirement, ensuring smooth integration into diverse industrial environments throughout India.

Robust Stainless Steel Build for Hygiene and Durability

Featuring a full stainless steel design, this milk filling machine prioritizes hygiene and long-term durability. Its easy-to-clean surfaces help maintain strict sanitary standards, making it ideal for dairy product handling.

FAQs of Milk Filling Machine:

Q: How does the Milk Filling Machine ensure accurate and consistent milk filling?

A: The machine utilizes an automated control system, either Human Machine Interface or PLC, paired with precise electric drive mechanisms. This combination allows it to fill bottles or containers from 100 mL to 2000 mL accurately, maintaining uniformity throughout production.Q: What materials are used in constructing the Milk Filling Machine?

A: This machine is crafted entirely from high-quality stainless steel (SS), a material known for its corrosion resistance and ease of cleaning, making it perfect for dairy industry applications where hygiene is paramount.Q: When does the warranty for the Milk Filling Machine become effective, and what does it cover?

A: The one-year warranty is activated from the date of purchase and covers manufacturing defects and functional issues not caused by operator error or misuse, providing peace of mind for distributors and users.Q: Where can this Milk Filling Machine be installed?

A: It is suitable for installation in dairy factories, milk processing plants, and packaging facilities across India. Its voltage can be customized as per the sites electrical requirements, ensuring compatibility with local standards.Q: What is the process of operating this Milk Filling Machine?

A: Operators simply set the desired fill quantity on the machines interface, load empty containers, and initiate the filling process. The automatic system manages the milk dispensing, ensuring consistent output and reducing manual intervention.Q: How does the Milk Filling Machine benefit dairy producers and packaging operations?

A: It increases productivity by automating the filling process, ensures hygiene through stainless steel construction, and reduces power consumption thanks to its eco-friendly electric design. Its versatility in capacity and control flexibility further enhances its value.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Liquid Filling Machine Category

8 Head Liquid Detergent Filling Machine

Price 800000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless steel

Control System : Human Machine Interface

Automatic Grade : Automatic

Volumetric Linear Bottle Filling Machine

Price 500000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Steel

Control System : Human Machine Interface

Automatic Grade : Automatic

Motor Oil Filling Machine

Price 2200000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : SS

Control System : Human Machine Interface

Automatic Grade : Automatic

Semi Automatic Toilet Cleaner - Acid Filling machine

Price 900000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Material : metal

Control System : PLC Control

Automatic Grade : SemiAutomatic

Let's talk business

Please take a moment to complete this form and a business representative will get back to you swiftly

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free