Induction Sealing machine

Price 350000 INR/ Unit

MOQ : 1 Unit

Induction Sealing machine Specification

- Usage

- Industrial

- Features

- Good Quality

- Material

- SS

- Computerized

- No

- Automatic Grade

- Automatic

- Control System

- Human Machine Interface

- Drive Type

- Electric

- Voltage

- 220-415 Volt (v)

- Color

- Silver

- Warranty

- 1 Year

Induction Sealing machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Delivery Time

- 5-10 Days

About Induction Sealing machine

Automatic Induction Sealing machine

Advantages of Induction Cap Sealing

- Tamper Proof: It is not possible, from production to the Consumer that the content of the product be manipulated without being clearly noticed.

- Product Freshness: The taste and aroma of the product remains intact due to the hermatic seal.

- Protection against Leakage: There is no spillage or loss of contents of the product.

- Sales Promotion: The foil on the inside can be used for advertising or promotional purposes.

- Maximum Filling Speeds: The sealing takes place without any direct contact which allows full potential of the filling plant to be utilsed. Minimum Effort: The wad is put in the cap by the manufacturers. Thus, the filling line requires only the Induction Cap Sealing equipment to be installed.

- Indirect Heating: Induction heating allows heat sensitive products such as creams, petroleum product, pesticides etc. to be sealed faster and safely than direct heating which would normally spoil or catch fire.

- IGBT Technology: IGBTs are more reliable and efficent at higher line speeds.

Advanced Induction Sealing Technology

Our induction sealing machine utilizes a sophisticated electric-driven system paired with a human machine interface for smooth operation. Made with top-grade stainless steel, it ensures durability and long-lasting performance. The automatic grade offers hands-free efficiency, making it perfect for high-volume industrial environments.

Reliable Performance and Support

Backed by a one-year warranty, this machine provides dependable service and customer support. The voltage flexibility between 220 and 415 volts allows integration into various industrial setups. As a trusted supplier in India, we offer expert guidance to help you select and maintain the right solution for your needs.

FAQs of Induction Sealing machine:

Q: How does the induction sealing machine operate?

A: The induction sealing machine uses electric power to heat a metallic liner placed on container closures, creating a secure and airtight seal. Its automatic system and human machine interface controller make the operation user-friendly and precise.Q: What industries can benefit from using this induction sealing machine?

A: This machine is designed for industrial usage, making it suitable for pharmaceuticals, food and beverage, chemicals, and cosmetic sectors where tamper-proof sealing and product integrity are essential.Q: When should I consider using an induction sealing machine for my production?

A: Induction sealing machines are ideal for operations requiring high-speed, consistent, and reliable lid sealing, particularly when packaging liquids or sensitive goods that benefit from leak-proof containment.Q: Where is this induction sealing machine available for purchase?

A: Our machines are available through authorized distributors, exporters, manufacturers, and suppliers across India. Contact us directly for information on local availability and support.Q: What is the installation process for this machine?

A: Installation is straightforward due to its automatic design and HMI control. Connect to a compatible power supply (220415 volts), position the machine in your production line, and follow the manufacturers setup guide to begin operation.Q: How does the warranty benefit users?

A: This induction sealing machine comes with a one-year warranty covering manufacturing defects, providing customers with peace of mind and support for any initial technical issues.Q: What advantages does the stainless steel construction offer?

A: Stainless steel ensures durability, corrosion resistance, and hygienic operation, which are critical factors for maintaining equipment longevity and compliance in industrial environments.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Automatic Packaging Machine Category

Pure Water Easy Operate Soft Drink Production Line

Minimum Order Quantity : 1 Piece

Control System : PLC Control

Computerized : Yes

Drive Type : Electric

Automatic Grade : Automatic

Stainless Steel Carbonated Beverage Bottling Equipment 15000 BPH Energy Saving

Price nan INR

Minimum Order Quantity : 1 Piece

Control System : PLC Control

Computerized : Yes

Drive Type : Electric

Automatic Grade : Automatic

Bottle Cartoning Machine

Minimum Order Quantity : 1 Piece

Control System : Human Machine Interface

Computerized : No

Drive Type : Electric

Automatic Grade : Automatic

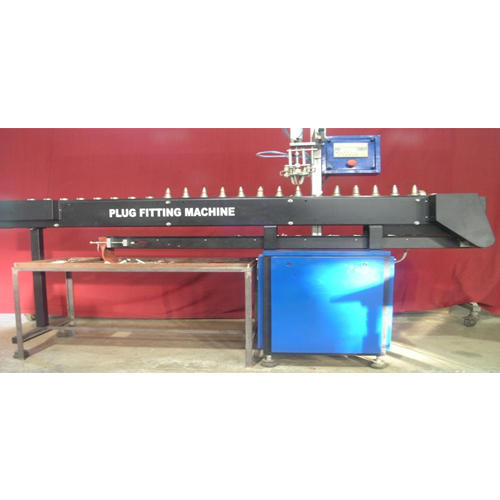

Plug Fitting Machine

Minimum Order Quantity : 1 Piece

Control System : PLC Control

Computerized : Yes

Drive Type : Electric

Automatic Grade : Automatic

Let's talk business

Please take a moment to complete this form and a business representative will get back to you swiftly

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free