Beverages Filling Machine

Beverages Filling Machine Specification

- Material

- Steel

- Application

- Beverage

- Computerized

- No

- Automatic Grade

- Automatic

- Drive Type

- Electric

- Voltage

- 220 Volt (v)

- Feature

- ECO Friendly

- Color

- Silver

- Warranty

- 1 Year

Beverages Filling Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 30 Pieces Per Month

- Delivery Time

- 8-10 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Packing Only

- Main Domestic Market

- All India

- Certifications

- CE & ISO Certified

About Beverages Filling Machine

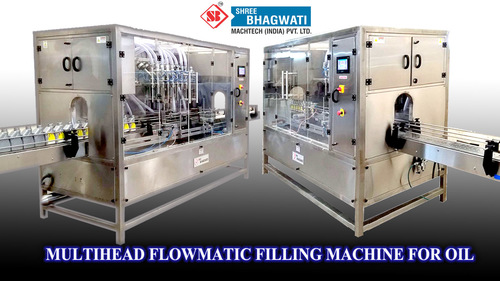

Beverages Filling Machine

| Bhagwati introduces filling machine for filling of all types of liquids. The filling machine comes with rotary filling with capping monoblock, volume adjustment block, a conveyor , filling nozzles, a no bottle no fill arrangement. | ||||||||

| Technical Specifications: |

||||||||

|

||||||||

|

Advanced Automation for Efficiency

Equipped with an intelligent PLC control system and computerized interface, this beverage filling machine automates the entire process, significantly reducing labor and minimizing errors. Its precision engineering ensures consistent product quality batch after batch, making it a dependable solution for beverage companies looking to scale production while maintaining standards.

Customizable Power and Versatile Filling

Adaptable to different operational needs, the machine supports a filling range from 200 ml up to 2000 ml, catering to a variety of bottle sizes and volumes. Clients can specify the required voltage to match their facilitys power standards, ensuring seamless integration with existing infrastructure and optimizing operational efficiency.

FAQs of Beverages Filling Machine:

Q: How does the automatic beverages filling machine work?

A: The machine operates by automatically dispensing precise amounts of beverages into containers, ranging from 200 ml to 2000 ml, controlled through a computerized PLC system. Operators simply set the required parameters, and the system handles the filling process efficiently and accurately.Q: What is the process for operating the filling machine?

A: To operate the machine, youll input your filling requirements into the PLC control panel, load the containers, and start the automatic cycle. The stainless steel construction ensures hygiene, while computerized controls provide consistent results without manual intervention.Q: When should I consider using this filling machine for my beverage line?

A: Consider using this filling machine when you need reliable, fast, and hygienic filling processes, especially if your production demands vary from 200 ml to 2000 ml per container and require automation to boost productivity.Q: Where can the beverages filling machine be installed?

A: The machine can be installed in beverage production facilities, bottling plants, or any industrial environment. The electric drive and voltage configuration can be customized as per customer requirements, making it suitable for businesses across India.Q: What are the main benefits of using this automatic filling machine?

A: Benefits include improved efficiency with automated operations, reduced labor costs, accurate and hygienic filling, robust stainless steel construction, and the added security of a 1-year warranty. The PLC control maximizes precision and minimizes product wastage.Q: How does the PLC control system contribute to efficiency?

A: The PLC control system allows for exact parameter setting and monitoring, minimizing human error and ensuring each fill volume is accurate. This results in faster production cycles and consistent quality, critical for beverage manufacturers.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Liquid Filling Machine Category

Milk Filling Machine

Price 1000000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Product Type : Other

Computerized : No

Control System : Human Machine Interface

4 Head Viscous Lotion Filling Machine

Price 1200000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Product Type : Lotion Filling Machine

Computerized : No

Control System : Human Machine Interface

Gel Filling Machine

Price 1200000 INR / Unit

Minimum Order Quantity : 1 Piece

Automatic Grade : Automatic

Product Type : Gel Filling Machine

Computerized : No

Control System : Human Machine Interface

Lubricant Oil Filling Machine

Price 1600000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Product Type : Lubricant Oil Filling Machine

Computerized : No

Control System : Human Machine Interface

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free